Method for preparing nanometer light adsorption material based on plant thylakoid structure

A light-absorbing material and plant-based technology, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of not being able to apply chloroplasts, not being able to obtain replicas of thylakoid structures, etc., to achieve high nano-layered structures and low cost low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Wash the fresh spinach leaves, remove the midrib, and put them in a refrigerator at 0-4°C to pre-cool. Configure the extract, weigh 60g sorbitol, 6.06g Tris, 1g MgCl 2 ·6H 2 O, 0.6g NaCl, 0.77g EDTA-Na 2 , 0.4g sodium erythorbate, add 1000ml distilled water, stir until completely dissolved. Adjust the pH to 7-8 with HCl. Take 10-20g of cooled spinach leaves, shred them, put them into a mortar, pour in the extract, grind them by hand for 1-2 minutes, and filter after grinding. Put the filtrate into a pre-cooled centrifuge tube and centrifuge for 2-4 minutes. The supernatant was poured off, and the precipitate was chloroplast.

[0026] (2) Preparing the precursor solution titanium tetrachloride alcohol solution, the preparation is specifically: under the condition of ice-water bath, anhydrous ethanol and titanium tetrachloride are mixed, the volume ratio is 44:4, and magnetically stirred for 10 minutes.

[0027] (3) The chloroplast extracted in the first step is...

Embodiment 2

[0034] (1) Wash fresh lettuce leaves, remove the midrib, pour the extract, grind and filter to obtain chloroplasts.

[0035] (2) Preparing the precursor solution titanium tetrachloride alcohol solution, the preparation is specifically: under the condition of ice-water bath, anhydrous ethanol and titanium tetrachloride are mixed with a volume ratio of 44:1, and magnetically stirred for 10 minutes.

[0036] (3) The chloroplast extracted in the first step is placed in the extraction solution prepared in the second step for ultrasonic treatment. The ultrasonic frequency is 40KHz, the ultrasonic power is 100W, and the time is 1 hour.

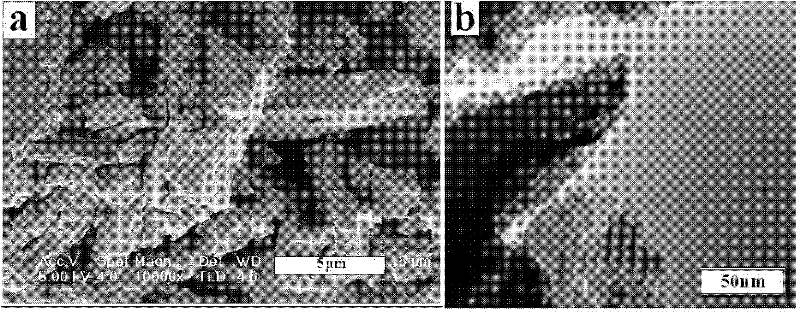

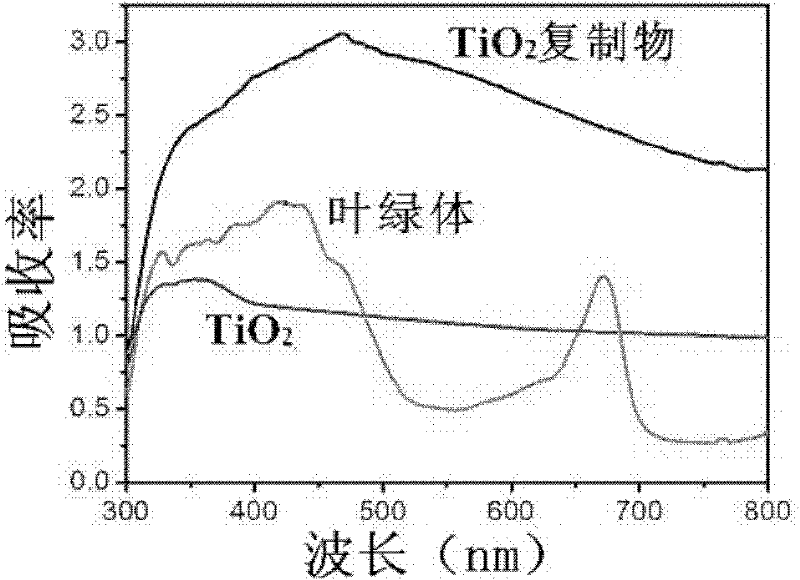

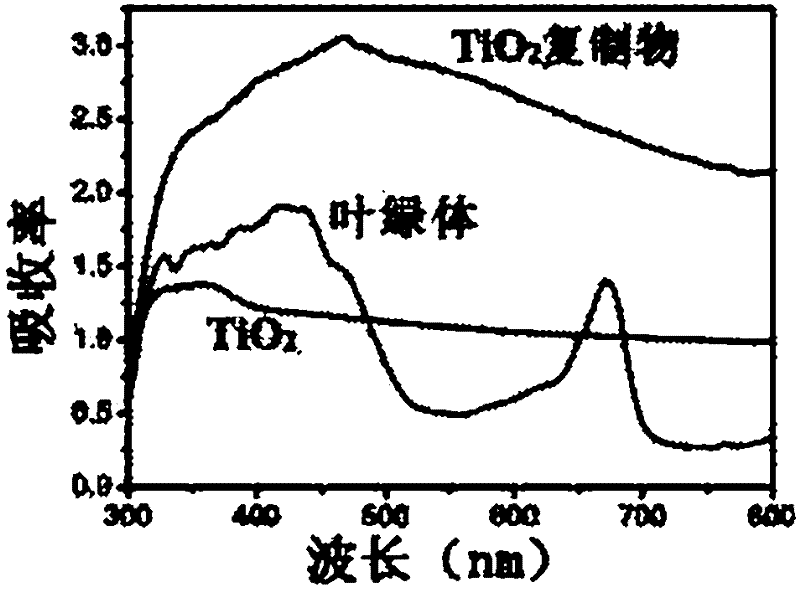

[0037] (4) After the sonication is finished, the sample is taken out and centrifuged. The supernatant liquid is poured off, and the precipitation is the viscous system in which the alcohol solution of titanium tetrachloride is immersed in the chloroplast. Roasting at 500°C, removing the biological template, yields titanium dioxide with a plant thyl...

Embodiment 3

[0039](1) Wash the fresh sycamore leaves, remove the midrib, pour the extract, grind and filter to obtain chloroplasts.

[0040] (2) Preparing the precursor solution titanium tetrachloride alcohol solution, the preparation is specifically: under the condition of ice-water bath, anhydrous ethanol and titanium tetrachloride are mixed with a volume ratio of 44:10, and magnetically stirred for 10 minutes.

[0041] (3) The chloroplast extracted in the first step is placed in the extraction solution prepared in the second step for ultrasonic treatment. The ultrasonic frequency is 60KHz, the ultrasonic power is 200W, and the time is 2 hours.

[0042] (4) After the sonication is finished, the sample is taken out and centrifuged. The supernatant liquid is poured off, the precipitate is the alcohol solution of titanium tetrachloride immersed in the viscous system of chloroplasts and roasted at 600°C, and the biological template is removed to obtain titanium dioxide with plant thylakoid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| mesopore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com