Preparation method of manganese dioxide one-dimensional nanomaterial

A nanomaterial, manganese dioxide technology, applied in the field of simple preparation of manganese dioxide one-dimensional nanomaterials, can solve the problems of limited commercial production, high cost, environmental pollution, etc., achieve low cost, easy mass production, and easy access to raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

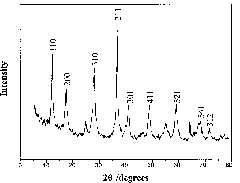

[0018] In a 100 ml beaker, add 30 ml of distilled or deionized water, and dissolve 2 mmol of potassium permanganate in water to obtain solution a. In addition, 20 ml of distilled water or deionized water was added into a 100 ml beaker, and 3 mmol of manganese acetate was dissolved in water to obtain solution b. Solution a and solution b were mixed, stirred, and transferred to a stainless steel hydrothermal reaction kettle with a polytetrafluoroethylene liner with a volume of 100 ml. The kettle was sealed and placed in a thermostat at 100°C for 12 hours. After natural cooling, the product was washed by suction filtration, washed with distilled water or deionized water and absolute ethanol until the pH was neutral, and dried in a normal pressure oven at 50°C for 12 hours to obtain MnO 2 One-dimensional nanomaterials. Its XRD spectrum is as figure 1 As shown, the analytical XRD spectrum shows that the prepared sample has a good crystal structure, and the crystal structure is α-...

Embodiment 2

[0021] In a 100 ml beaker, add 30 ml of distilled or deionized water, and dissolve 5 mmol of potassium permanganate in water to obtain solution a. In addition, 20 ml of distilled water or deionized water was added into a 100 ml beaker, and 7.5 mmol of manganese acetate was dissolved in water to obtain solution b. Solution a and solution b were mixed, stirred, and transferred to a stainless steel hydrothermal reaction kettle with a polytetrafluoroethylene liner with a volume of 100 ml. The kettle was sealed and put into a thermostat at 140° C. for 8 hours. After natural cooling, the solid-liquid separation method was adopted by centrifugal washing, washed with distilled water or deionized water until the pH was neutral, and then vacuum-dried at 80°C for 10 hours to obtain MnO 2 One-dimensional nanomaterials.

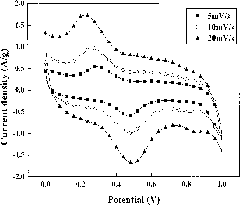

[0022] MnO prepared by 2 Active material, acetylene black AB as conductive agent, polyvinylidene fluoride PVDF as binder, MnO 2 The mass ratio of AB:PVDF is 80:10:10 t...

Embodiment 3

[0027] In a 100 ml beaker, add 30 ml of distilled or deionized water, and dissolve 7.5 mmol of potassium permanganate in water to obtain solution a. In addition, 20 milliliters of distilled water or deionized water was added into a 100 milliliter beaker, and 11.25 millimoles of manganese acetate was dissolved in water to obtain solution b. Solution a and solution b were mixed, stirred, and transferred to a stainless steel hydrothermal reaction kettle with a polytetrafluoroethylene liner with a volume of 100 ml. The kettle was sealed and put into a thermostat at 150° C. for 6 hours. After natural cooling, adopt the method of centrifugal washing and solid-liquid separation, wash with distilled water or deionized water until the pH is neutral, and then vacuum dry at 100°C for 6 hours to obtain MnO 2 One-dimensional nanomaterials.

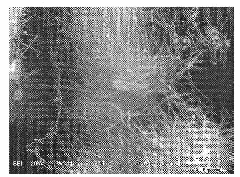

[0028] The as-prepared material was observed with a LEO1525 scanning electron microscope. Figure 5 shown. From Figure 5 It can be seen that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com