Method for commixing vulcanized rubber powder produced by utilizing waste rubber and rubber plastic material

A technology for vulcanized rubber powder and waste rubber, which is applied in the field of resource utilization of waste rubber. It can solve the problems of not being able to effectively improve and improve the performance of products, the compatibility of vulcanized rubber powder and the blending system, and the inability to improve vulcanization. Issues such as the amount of rubber powder blending, to achieve excellent physical and chemical properties, increase the use value, low temperature and other performance improvements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

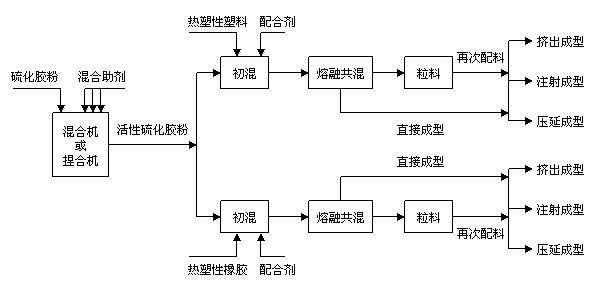

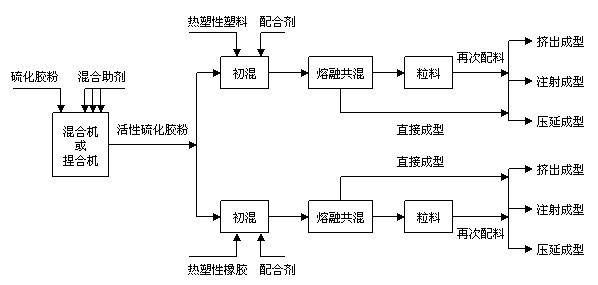

Image

Examples

Embodiment 1

[0020] Example 1: Preparation and blending application of reactive vulcanized rubber powder blended with thermoplastics

[0021] Step 1. Waste tire vulcanized rubber powder with a particle size below 150 microns (that is, passing through a 100-mesh sieve) is put into the mixer (or kneader), and compound additives are added according to the following ratio: active dispersant: n-butyl xanthogen Sodium acid, 1.0%, disproportionated rosin, polymerized rosin, each 0.5%; Compatibility modifier: piperylene petroleum resin, 1.0%, xylene-formaldehyde resin, 0.5%, stearic acid amide, oleic acid amide, 0.5% each. Stir for 5-10 minutes to mix evenly.

[0022] Step 2: Blending with thermoplastics, the ratio of ingredients: polystyrene / PS, 20%; linear low density polyethylene / LLDPE, 20%; chlorinated polyethylene / CPE, 10%; active vulcanized rubber powder, 50% %; processing compound species and dosage, composite antioxidant 1010, 0.3%.

[0023] Step 3: Melting and blending with an extruder...

Embodiment 2

[0025] Example 2: Preparation and blending application of active vulcanized rubber powder blended with thermoplastic rubber

[0026] Step 1. Waste tire vulcanized rubber powder with a particle size below 150 microns (that is, passing through a 100-mesh sieve) is put into the mixer (or kneader), and compound additives are added according to the following ratio: active dispersant: n-butyl xanthogen Zinc acid, 1.0%, hydrogenated rosin, maleic rosin, each 0.5%; Compatibility modifier: Bicyclic

[0027] Pentadiene petroleum resin, 1.0%, xylene-formaldehyde resin, 0.5%, stearic acid amide, erucic acid amide, each 0.5%. Stir for 5-10 minutes to mix evenly.

[0028] Step 2. Blending with thermoplastic rubber. Ratio of ingredients: styrene-butadiene-styrene block copolymer / SBS, 60%; active vulcanized rubber powder, 40%; compounding agent type and dosage, compound antioxidant Agent 1010, 0.3%.

[0029] Step 3: Melting and blending with an open mill to make flakes, and directly calend...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com