Preparation method of rare earth ion-doped Lu2O3 light-emitting film

A technology of rare earth ions and light-emitting films, applied in light-emitting materials, chemical instruments and methods, etc., can solve problems such as non-uniform capillary stress, uneven pore size distribution, and film cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

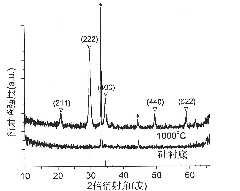

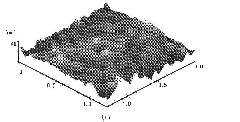

Image

Examples

Embodiment 1

[0031] 5g LuCl 3 ·6H 2 O powder was added into 50ml of absolute ethanol, and stirred at 100°C for 2h to completely dissolve the powder to obtain a transparent solution. Thereafter, 2.5 g of polyethylene glycol (molecular weight 6000), 6.5 g of citric acid and 6 ml of water were added and stirred at room temperature for 2 h to obtain a transparent sol. According to the concentration requirement, add 0.7ml Eu(NO 3 ) 3 The solution (0.916mol / L) was added to the sol and stirred for about half an hour to obtain the required precursor sol.

[0032] The Si single wafer used to grow thin films needs to be ultrasonically cleaned with ethanol and deionized water for 20 minutes, and then soaked in a mixture of concentrated sulfuric acid and concentrated phosphoric acid (volume ratio: 3:1) for 24 hours to remove impurities on the surface of the silicon wafer. . The pre-configured sol was dropped onto the surface of the Si substrate, and the colloid was evenly coated on the substrate ...

Embodiment 2

[0042] 5g LuCl 3 ·6H 2 O powder was added into 40ml of absolute ethanol, and stirred at 100°C for 2h to completely dissolve the powder to obtain a transparent solution. Thereafter, 2.5 g of polyethylene glycol (molecular weight 6000), 6.5 g of citric acid and 5 ml of water were added and stirred at room temperature for 2 h to obtain a transparent sol. According to the concentration requirement, add 2.6ml Tb(NO 3 ) 3 The solution (0.048mol / L) was added to the sol and stirred for about half an hour to obtain the required precursor sol.

[0043] The Si single wafer used to grow thin films needs to be ultrasonically cleaned with ethanol and deionized water for 20 minutes, and then soaked in a mixture of concentrated sulfuric acid and concentrated phosphoric acid (volume ratio: 3:1) for 24 hours to remove impurities on the surface of the silicon wafer. . The pre-configured sol was dropped onto the surface of the Si substrate, and the colloid was evenly coated on the substrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com