Method for preparing air purifying fabric by biomimetic synthesis low-temperature in-site secondary growth process

A low-temperature in-situ, secondary growth technology, applied in the direction of plant fibers, animal fibers, textiles and paper, can solve the problems of flexible substrates easy to photooxidative degradation, flexible substrates are not resistant to high temperature, low catalytic efficiency, etc., to achieve The effect of avoiding the reduction of agglomeration efficiency, strong oxidation ability, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

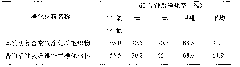

Embodiment 1

[0030] (1) Preparation of antioxidant finishing solution

[0031] Mix 500ml of absolute ethanol, 0.5g of ammonium chloride, 200ml of distilled water and 100ml of acetone evenly, and then add 20ml of 3-glycidyl propyl ether methoxysilane dropwise to obtain a biomimetic protection and anti-oxidation finishing solution;

[0032] (2) Protective finishing of wool fabric against photooxidation

[0033] Soak the wool fabric in the above finishing solution, keep stirring at room temperature for 4 hours at 200rpm, take it out, rinse with distilled water and ethanol, and dry at 100°C;

[0034] (3) Surface pretreatment of wool fabric after anti-photooxidation protection

[0035] The wool fabric after the above treatment is immersed in the pretreatment solution for 5min, then rinse the fabric with deionized water to remove excess electrolyte, and dry; the pretreatment solution is dimethyldiallyl chloride with a mass fraction of 1%. ammonium chloride, 0.5% polystyrene, 20% sodium chlorid...

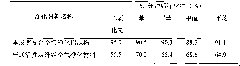

Embodiment 2

[0045] (1) Preparation of antioxidant finishing solution

[0046] Mix 600ml of absolute ethanol, 2g of octyltrimethoxysilane, 500ml of distilled water and 200ml of acetone evenly, then add 50ml of silane dropwise to obtain a biomimetic protection and anti-oxidation finishing solution;

[0047] (2) Protective finishing of cotton fabric against photooxidation

[0048]Soak the cotton fabric in the above finishing solution, keep stirring at room temperature for 8 hours at 400rpm, take it out, rinse it with distilled water and ethanol, and dry it at 130°C;

[0049] (3) Cotton fabric surface pretreatment after anti-photooxidation protection

[0050] The cotton fabric after the above treatment is immersed in the pretreatment solution for 15min, then rinse the fabric with deionized water to remove excess electrolyte, and dry; the pretreatment solution is 3% dimethyl diallyl chloride ammonium chloride, 1% polystyrene, 30% sodium chloride, and the rest is water;

[0051] (4) Preparat...

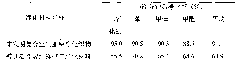

Embodiment 3

[0060] (1) Preparation of antioxidant finishing solution

[0061] Mix 700ml of absolute ethanol, 2.5g of ammonium hydrogen phosphate, 400ml of distilled water and 200ml of acetone evenly, and then add 50ml of phenyltrimethoxysilane drop by drop to configure a biomimetic protection and anti-oxidation finishing solution;

[0062] (2) Protective finishing of linen fabric against photooxidation

[0063] Soak the linen fabric in the above finishing solution, keep stirring at room temperature for 5 hours at 300rpm, take it out, rinse it with distilled water and ethanol, and dry it at 120°C;

[0064] (3) Surface pretreatment of linen fabric after anti-photooxidation protection

[0065] The linen fabric after above-mentioned treatment is soaked in the pretreatment solution 15min, then rinses the fabric with deionized water to remove excess electrolyte, and dries; The pretreatment solution is dimethyldiallyl chloride with a mass fraction of 3%. ammonium chloride, 0.5-1% polystyrene, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com