Method for preparing eriocalyxin B

A kind of technology of eriophyllin and echinococcinus, which is applied in the field of pharmacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

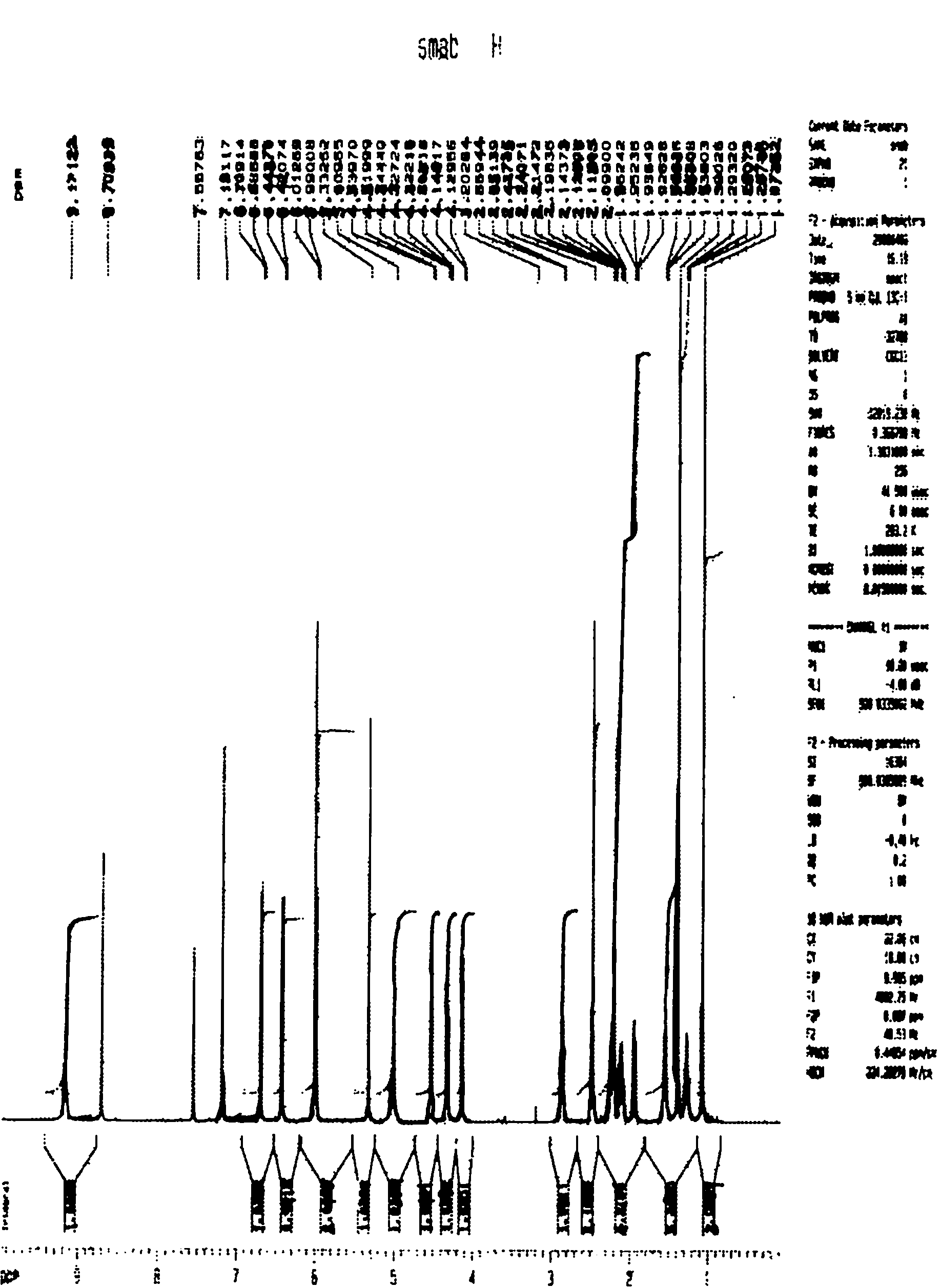

Image

Examples

Embodiment 1

[0018] 1. The preparation of the crude product of Eriophyllin:

[0019] Take 1 kg of the above-ground part of Calyx spp., put it in a 10-liter percolation tank after crushing, extract 3 times by diafiltration at room temperature with 10 liters of 95% ethanol (3 times share 20 liters), and combine the percolation extracts (about 15 liters). liter), concentrated in a spherical concentrator to obtain 67.8 grams of extract, added 120mL of water and stirred evenly, and the aqueous phase was extracted with the same volume of ethyl acetate (V:V=1:1, extracted three times) to obtain ethyl acetate Part 62.7 grams; this extract is dissolved in 95% ethanol, after filtering, put on the MCI column to remove the pigment, flush the column with 90% ethanol, and wash the column with acetone after the fraction containing echinoceline is washed. After concentration of the fraction containing calyxin, 58.8 grams of the crude extract of calyx sp.

[0020] 2, the preparation of calyxin B:

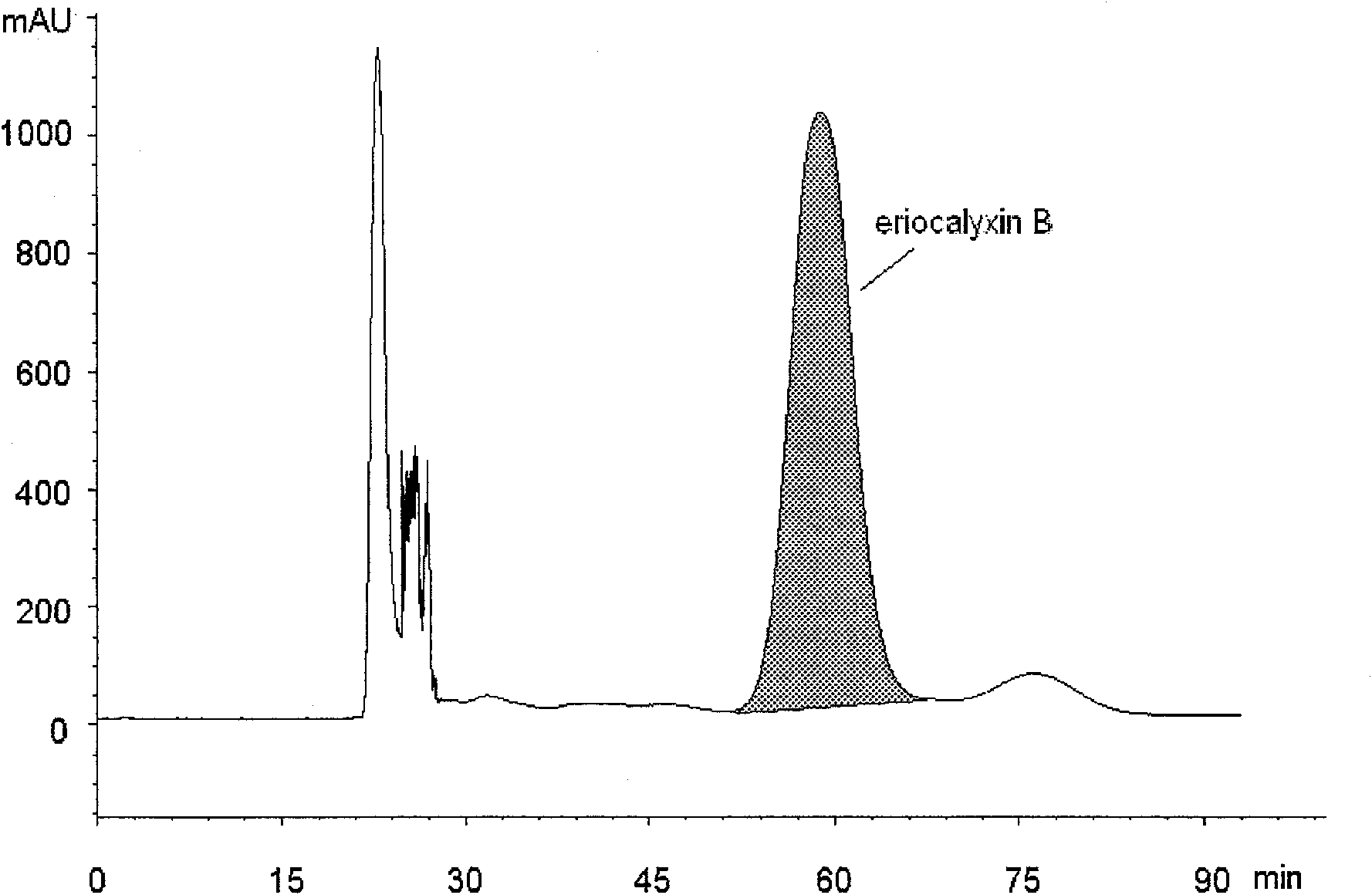

[0021...

Embodiment 2

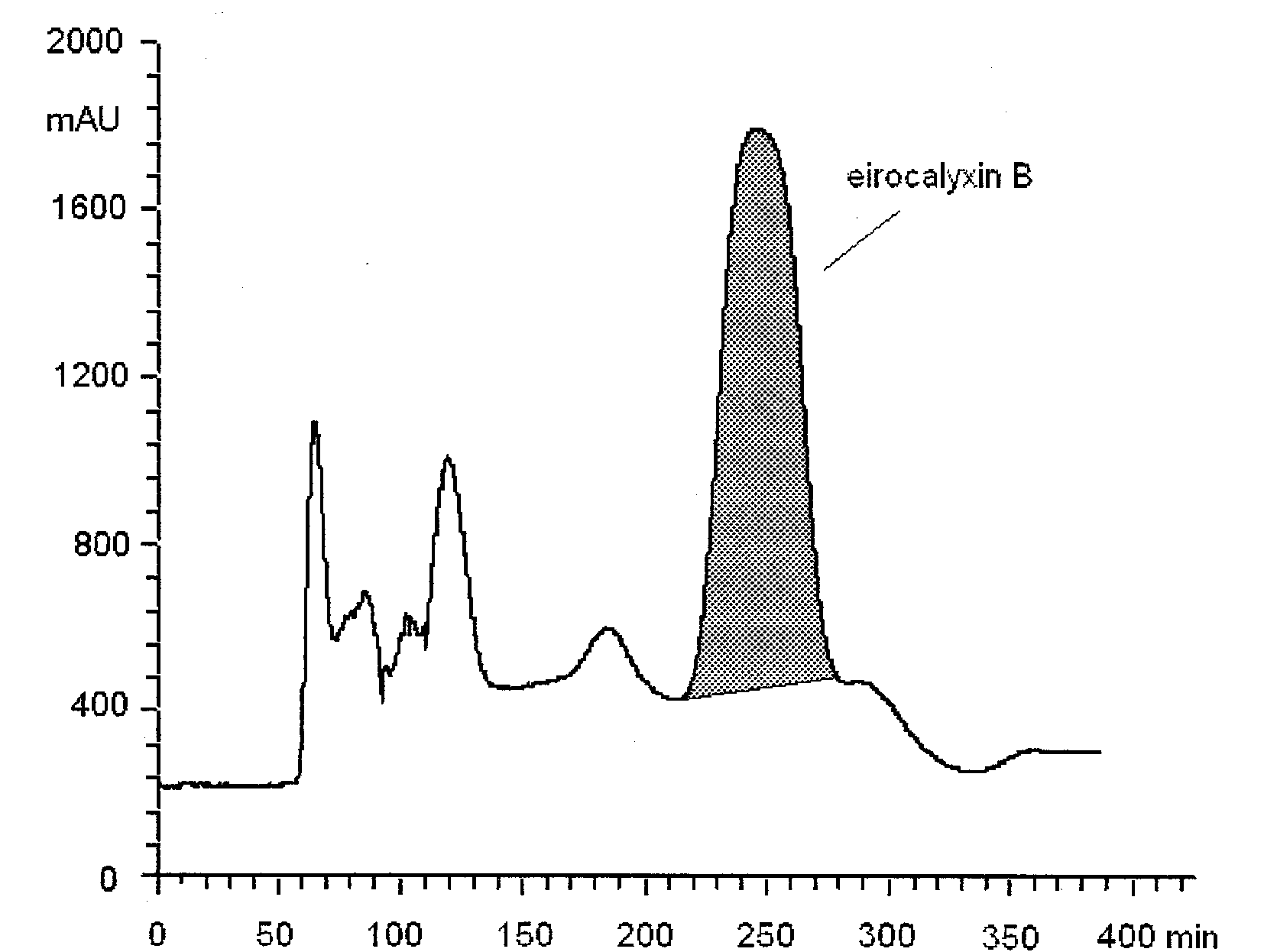

[0025] A semi-preparative TBE-300B high-speed countercurrent chromatograph is used, equipped with a plunger pump, injection valve, ultraviolet detector and recorder, and the column capacity of multi-layer wound polytetrafluoroethylene is about 260mL. The solvent system was n-hexane / ethyl acetate / methanol / water 5:5:5:5 for the separation and preparation of echinacetin monomer. Firstly, the above-mentioned solvent system was arranged in a separatory funnel, shaken evenly and allowed to stand to separate into layers. After equilibrating for a period of time, separate the upper phase and the lower phase, and take the upper phase as the stationary phase and the lower phase as the mobile phase. Take 500 mg of the crude extract of Calyx sphaericus and dissolve it in the mixture of 5 mL of the upper phase and 5 mL of the lower phase for use. First fill the entire column with the stationary phase; adjust the speed of the main engine to 800rpm, and pump the mobile phase into the column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com