Preparation method of lithium ion battery ferric metasilicate lithium positive electrode material

A lithium ion battery, lithium iron silicate technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of unfavorable lithium iron silicate electrochemical performance, unfavorable battery volume energy density, large crystal grains and particles of materials, etc. Achieving the effect of excellent microstructure, excellent electrochemical performance and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The steps of the preparation method of the lithium-ion battery lithium iron silicate cathode material of the present embodiment are as follows: the basic raw material Li 2 CO 3 , FeC 2 o 4 2H 2 O, SiO 2 Mix in a molar ratio of 1:1:1, then add carbon source compound sucrose whose mass is 10% of the mass of the basic raw material and heat conduction agent acetylene black with a mass of 0.5% of the mass of the basic raw material, fully grind and mix with ethanol as a dispersant, and dry it in Press it into a block with a thickness of 1.5cm under a pressure of 10MPa, then place it in a crucible filled with activated carbon, then place the crucible in a microwave oven, and sinter at low heat for 5min to obtain a carbon-coated lithium iron silicate cathode material.

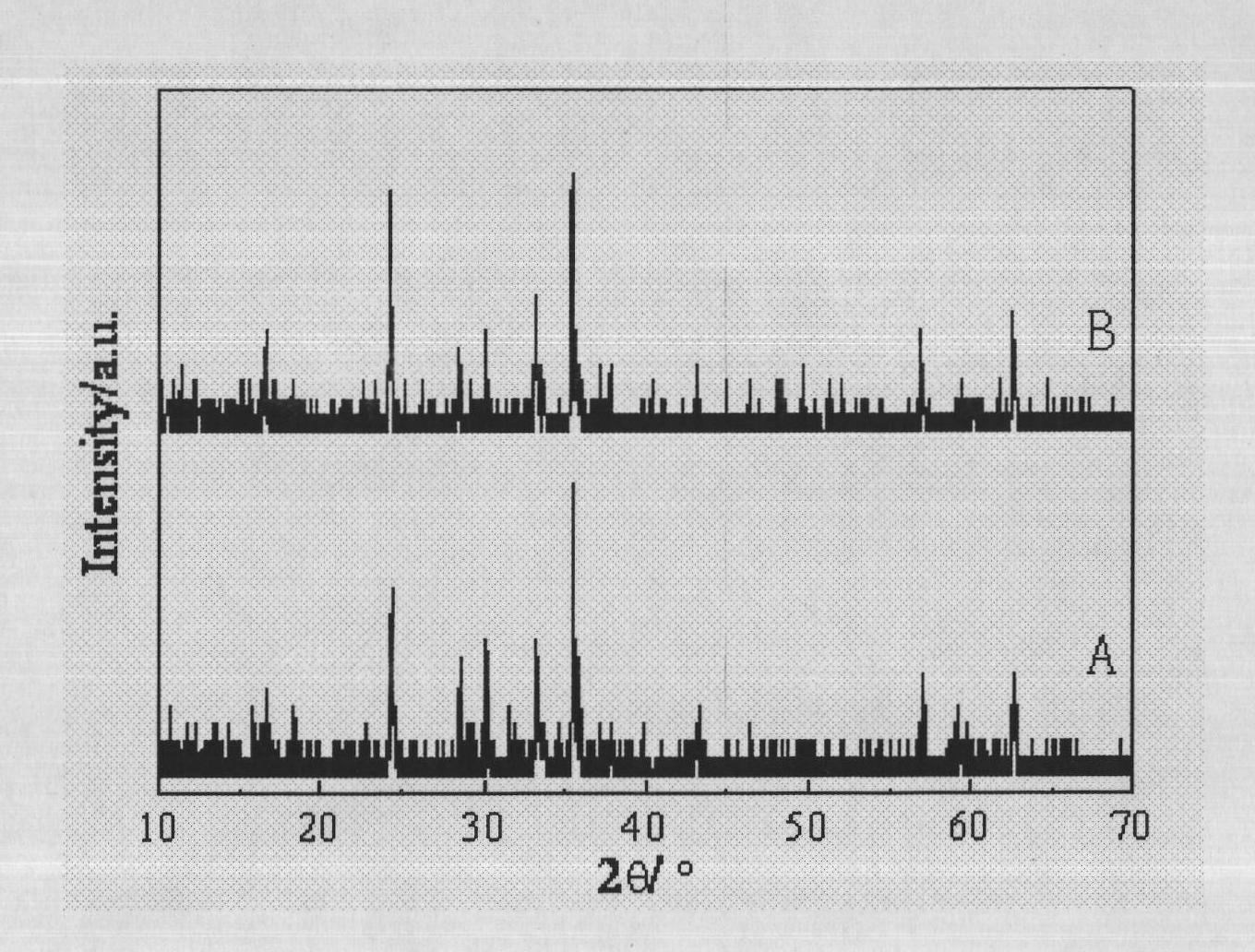

[0023] Such as figure 1 As shown in the curve A, the carbon-coated lithium iron silicate positive electrode material obtained in this embodiment is a single lithium iron silicate phase, and the crystallizat...

Embodiment 2

[0028] The steps of the preparation method of lithium iron silicate cathode material for lithium ion battery of the present embodiment are as follows: the basic raw materials LiOH, FeC 2 o 4 2H 2 O, SiO 2 Mix at a molar ratio of 2:1:1, then add 10% of the coating glucose as the mass of the basic raw material and 0.5% of the heat conduction agent activated carbon as the mass of the basic raw material, fully grind and mix with ethanol as a dispersant, and dry it at 10MPa Press it into a block with a thickness of 1.3 cm, place it in a crucible filled with activated carbon, place the crucible in a microwave oven, and sinter at low heat for 7 minutes to obtain a carbon-coated lithium iron silicate cathode material.

[0029] Such as figure 1 As shown in the curve B, the carbon-coated lithium iron silicate positive electrode material obtained in this embodiment is a single lithium iron silicate phase, and the crystallization performance of the product is good.

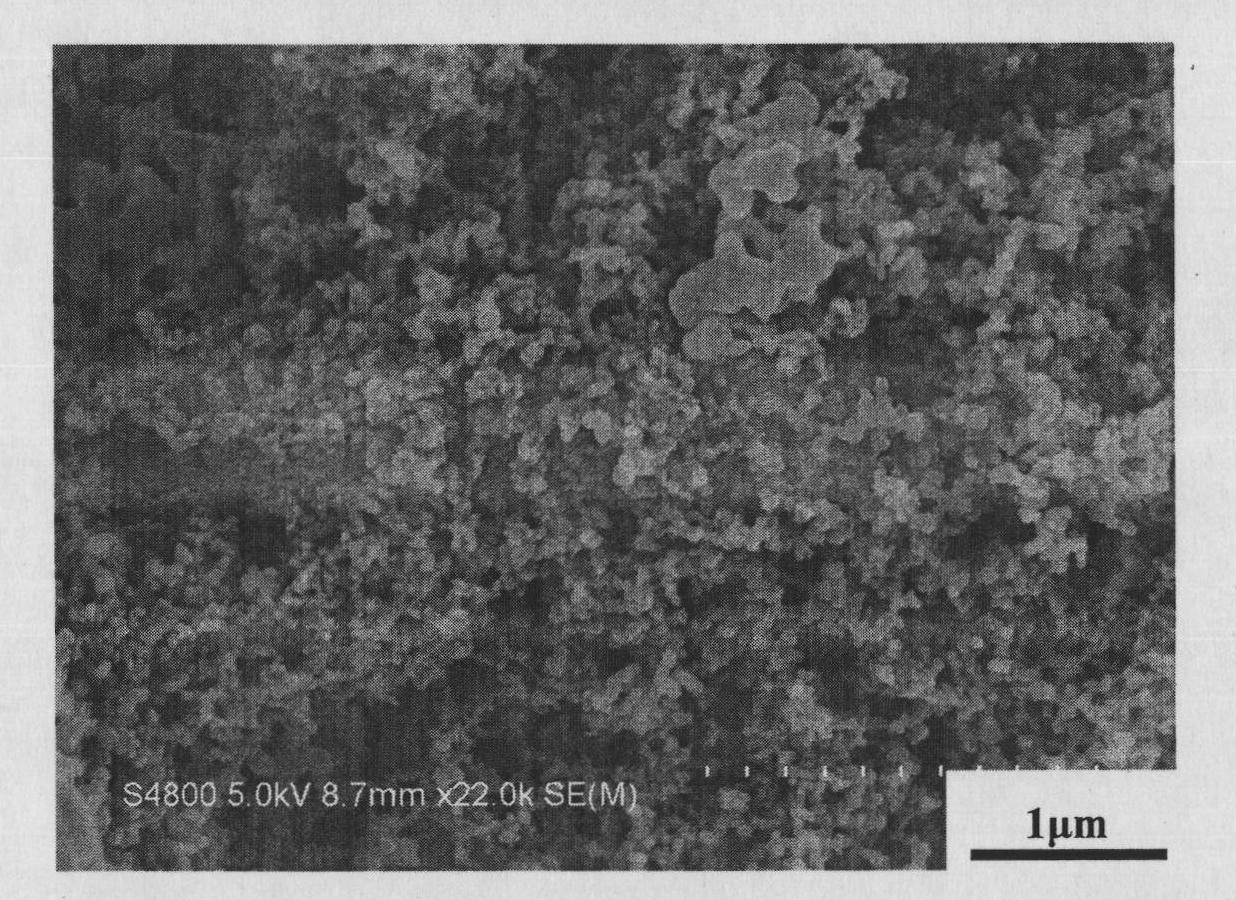

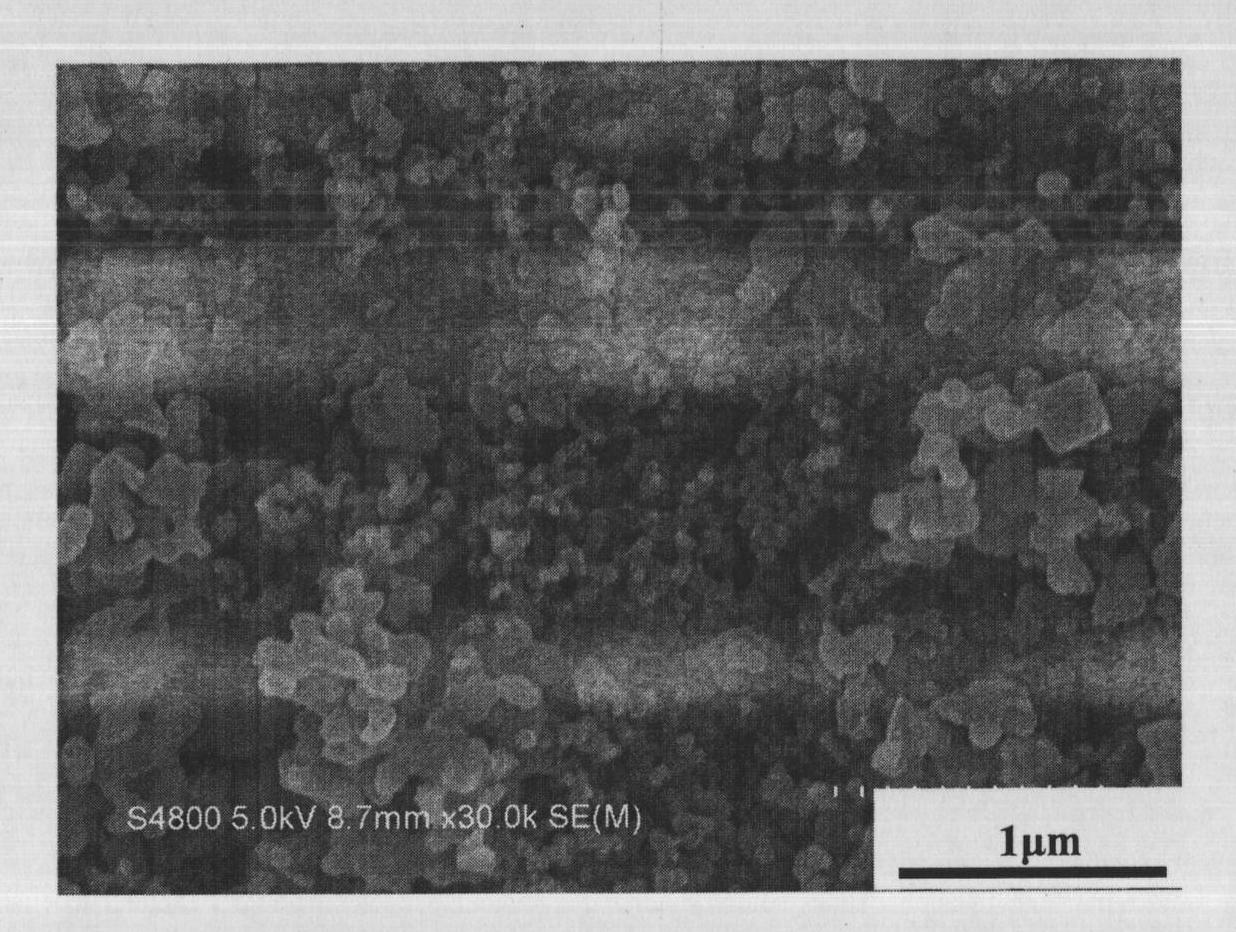

[0030] Such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com