Method for preparing titanium dioxide ultraviolet photoelectric detector

An electrical detector, titanium dioxide technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of high responsivity, large dark current, high UV-visible suppression ratio, and achieve the effect of simple process, easy integration and industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

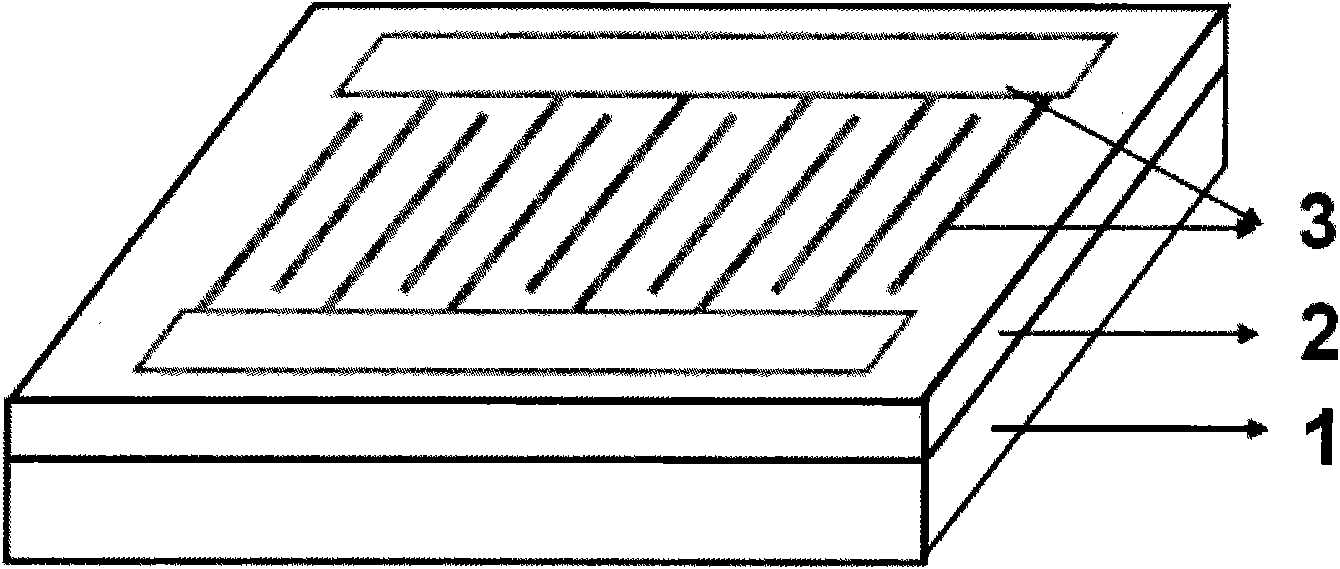

[0031] High-performance TiO prepared by the present invention 2 MSM-based UV photodetectors, interdigital electrode materials can be selected from metals with high work functions such as Au, Pt and Ni; insulating substrates can be selected from quartz glass, sapphire, and silicon wafers grown with silicon oxide or silicon nitride insulating layers . If it is made on a silicon wafer substrate, it can be compatible with the mature Si process, which is conducive to optoelectronic integration and easy to industrialize. The following uses quartz glass as the substrate and Au as the metal electrode to illustrate the preparation and implementation process of the detector of the present invention.

[0032] The specific steps are given below:

[0033] (1) Substrate treatment

[0034] Quartz glass (thickness 0.5mm, diameter 1inch) was selected as the insulating substrate, and the substrate was placed in toluene, acetone, ethanol and deionized water in sequence for ultrasonic cleaning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com