MoO3 and ordered mesoporous carbon composite electrode material and preparation method thereof

A composite electrode and mesoporous carbon technology, which is applied in carbon-silicon compound conductors, cable/conductor manufacturing, circuits, etc., can solve the problems of phase change, collapse of pore structure, and agglomeration of metal oxide particles, and achieves low equipment requirements. The preparation process is simple and the effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

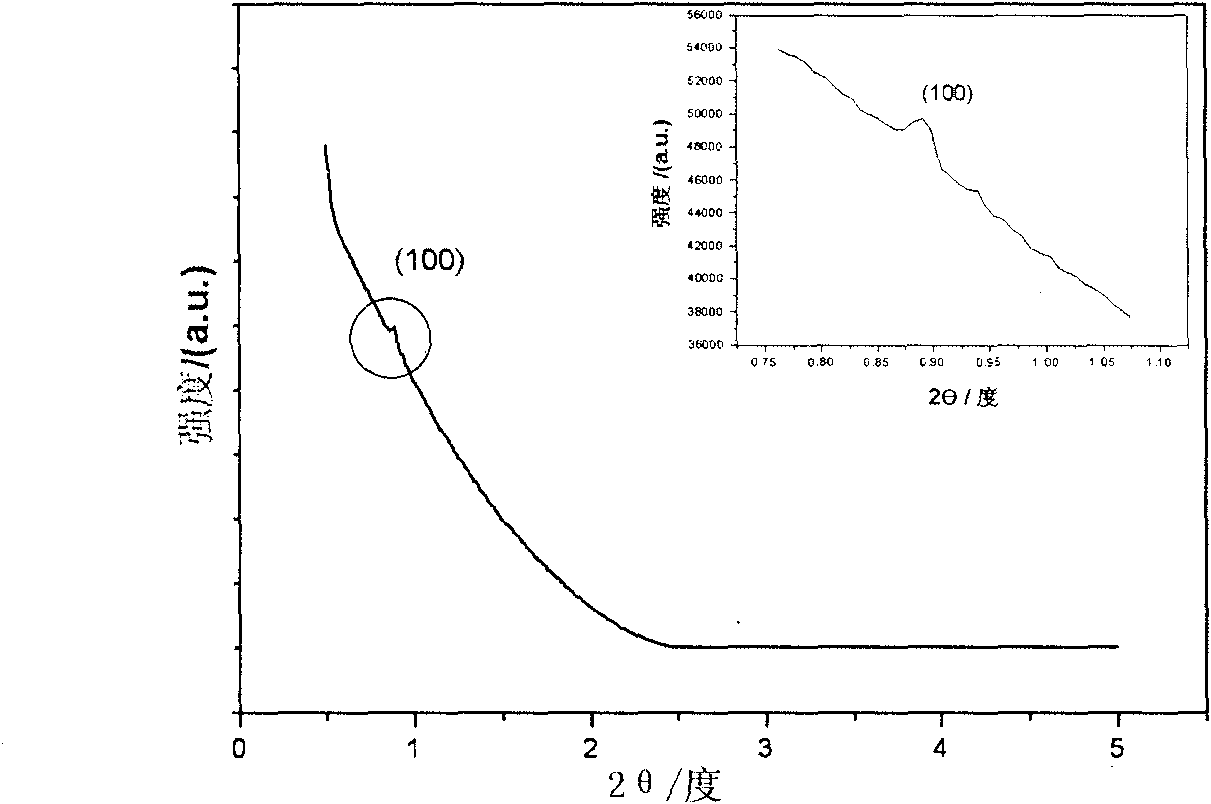

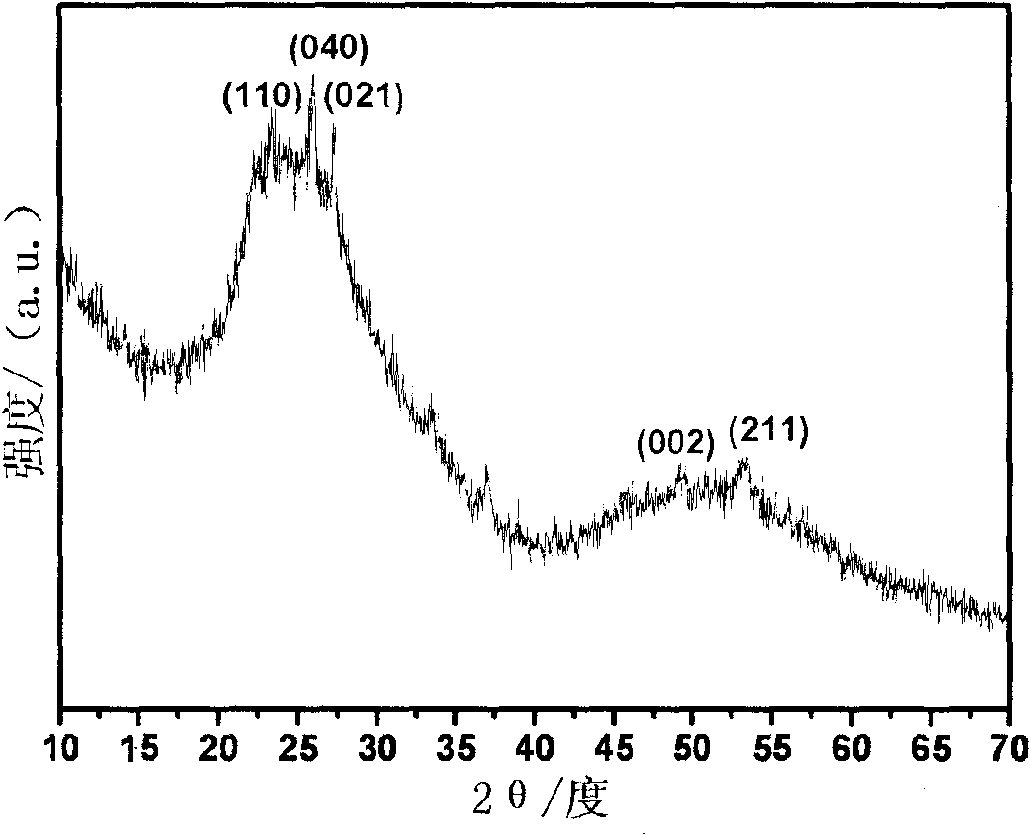

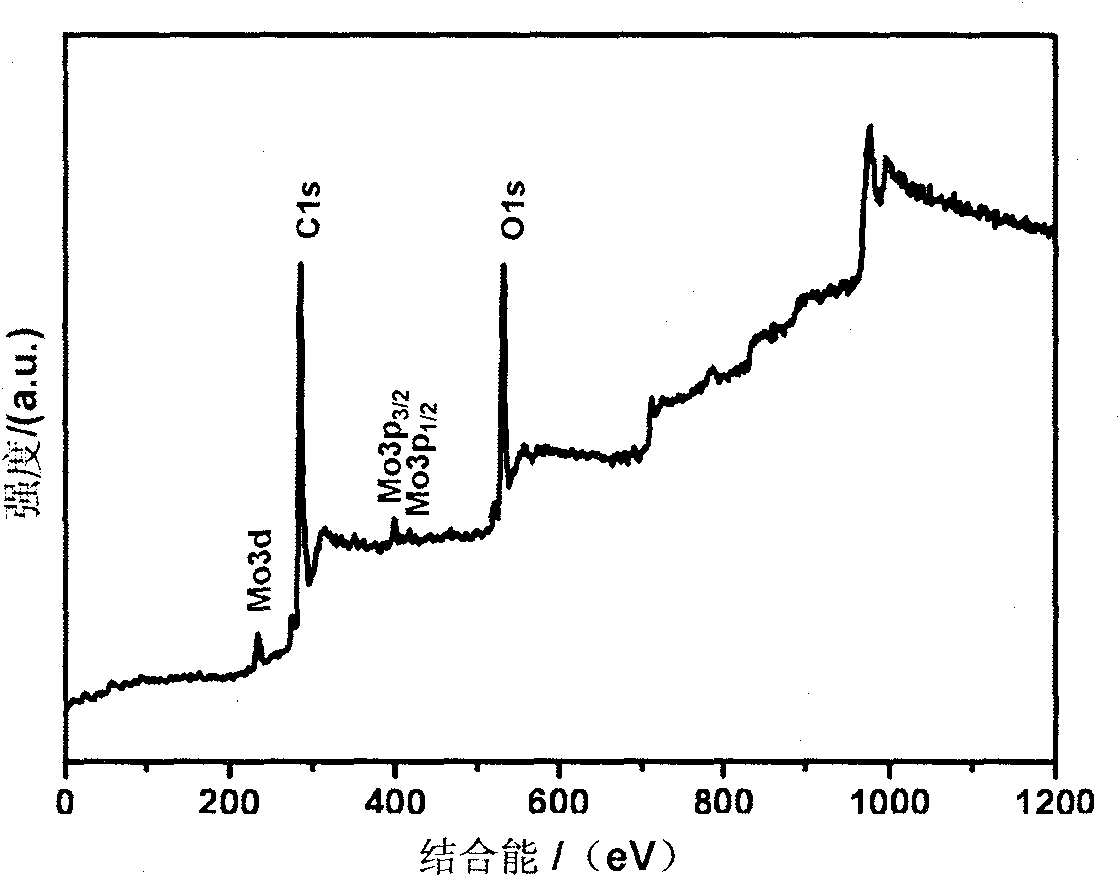

[0030] MoO 3 Prepare the composite electrode material with ordered mesoporous carbon, the steps are:

[0031] (1) Synthesis of ordered mesoporous carbon CMK-3: 1g of mesoporous silica SBA-15 was added to sulfuric acid-containing sucrose aqueous solution (configured according to 1.25g sucrose, 0.2g sulfuric acid and 5g water), and stirred for 2-4h. The mixture was placed in a drying oven and kept at 50°C for 12h, then the temperature was raised to 160°C for 6h. Add 0.75g of sucrose, 0.1g of sulfuric acid and 5g of water to the above partially polymerized silica sample, stir evenly, and perform the same treatment in a drying oven at 50°C and 160°C respectively. Then, under a nitrogen protective atmosphere, the temperature was raised to 900°C at a rate of 250°C / h for 6 hours to complete the entire carbonization process. The obtained silica / carbon composite product was impregnated with 10 wt% hydrofluoric acid solution to remove the template. The final product is filtered, wash...

Embodiment 2~ Embodiment 4

[0036] Example number

[0037] According to the above experimental parameters with reference to the method of Example 1 to obtain MoO 3 Composite electrode materials with ordered mesoporous carbons.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com