Glove box protective argon arc welding method

A glove box and argon arc welding technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of no uniform standard for argon arc welding process parameters, low qualified rate of welding finished products, and inability to weld in batches, etc., to achieve Improved anti-oxidation effect, high welding efficiency, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A glove box protected argon arc welding method, specifically comprising the following steps:

[0025] (1) Turn on the power, open the argon valve in the pipeline, turn on the micro oxygen meter and dew point meter, press the cleaning button, wait until the oxygen content reaches 50PPM, and the water content reaches -50, turn off the cleaning button, open the cycle button, and enter the dehydration and dewatering oxygen state;

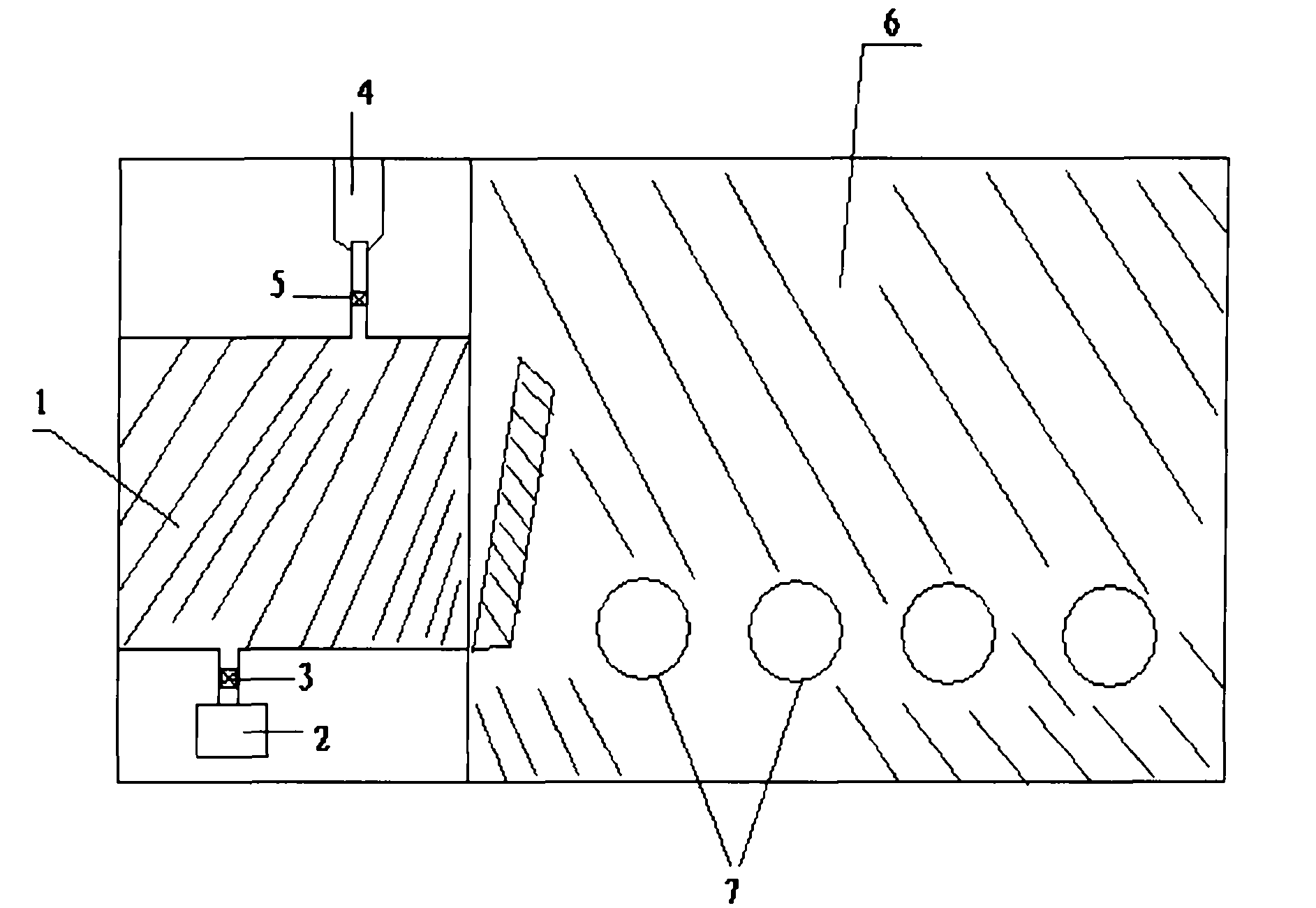

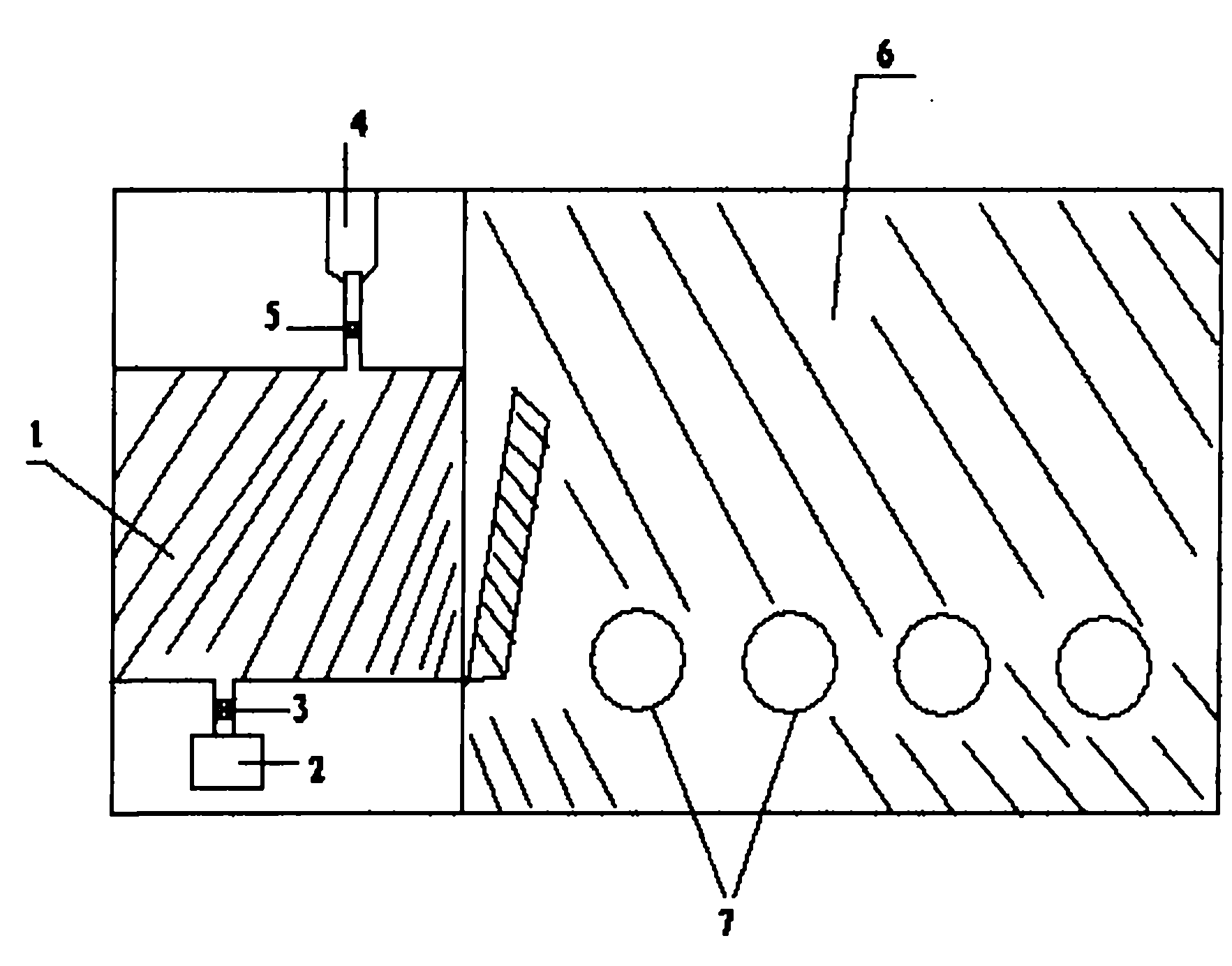

[0026] (2) Open the outer door of the transition chamber (1), place the workpiece to be welded on the stage of the transition chamber (1), close the outer door of the transition chamber (1), and open the exhaust valve (3) of the vacuum pump (2). Vacuum until the pressure gauge reaches zero, close the pumping valve (3), open the inflation valve (5) of the argon cylinder (4), and fill the transition chamber (1) and glove box (6) with argon until the pressure gauge is full , close the inflation valve (5), open the exhaust valve (3) again to evacuat...

Embodiment 2

[0030] A glove box protected argon arc welding method, specifically comprising the following steps:

[0031] (1) Turn on the power, open the argon valve in the pipeline, turn on the micro oxygen meter and dew point meter, press the cleaning button, wait until the oxygen content reaches 10PPM, and the water content enters -60, turn off the cleaning button, open the cycle button, and enter the dehydration and dewatering oxygen state;

[0032] (2) Open the outer door of the transition chamber (1), place the workpiece to be welded on the stage of the transition chamber (1), close the outer door of the transition chamber (1), and open the exhaust valve (3) of the vacuum pump (2). Vacuum until the pressure gauge reaches zero, close the pumping valve (3), open the inflation valve (5) of the argon cylinder (4), and fill the transition chamber (1) and glove box (6) with argon until the pressure gauge is full , close the inflation valve (5), open the exhaust valve (3) again to evacuate t...

Embodiment 3

[0036] A glove box protected argon arc welding method, specifically comprising the following steps:

[0037] (1) Turn on the power, open the nitrogen valve of the pipeline, turn on the micro oxygen meter and dew point meter, press the cleaning button, wait until the oxygen content reaches 20PPM, and the water content enters -40, turn off the cleaning button, open the cycle button, and enter the water removal and oxygen removal state;

[0038] (2) Open the outer door of the transition chamber (1), place the workpiece to be welded on the stage of the transition chamber (1), close the outer door of the transition chamber (1), and open the exhaust valve (3) of the vacuum pump (2). Vacuum until the pressure gauge reaches zero, close the pumping valve (3), open the inflation valve (5) of the argon gas cylinder (4), and fill the transition chamber (1) and the glove box (6) with nitrogen until the pressure gauge is full. Close the inflation valve (5), open the exhaust valve (3) again...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com