Production technique of high-activity plating-grade copper oxide

A technology of electroplating grade copper oxide and production process, applied in copper oxide/copper hydroxide and other directions, can solve problems such as environmental pollution, low copper oxide activity, activity verification, etc., and achieve low impurity content, high activity, and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

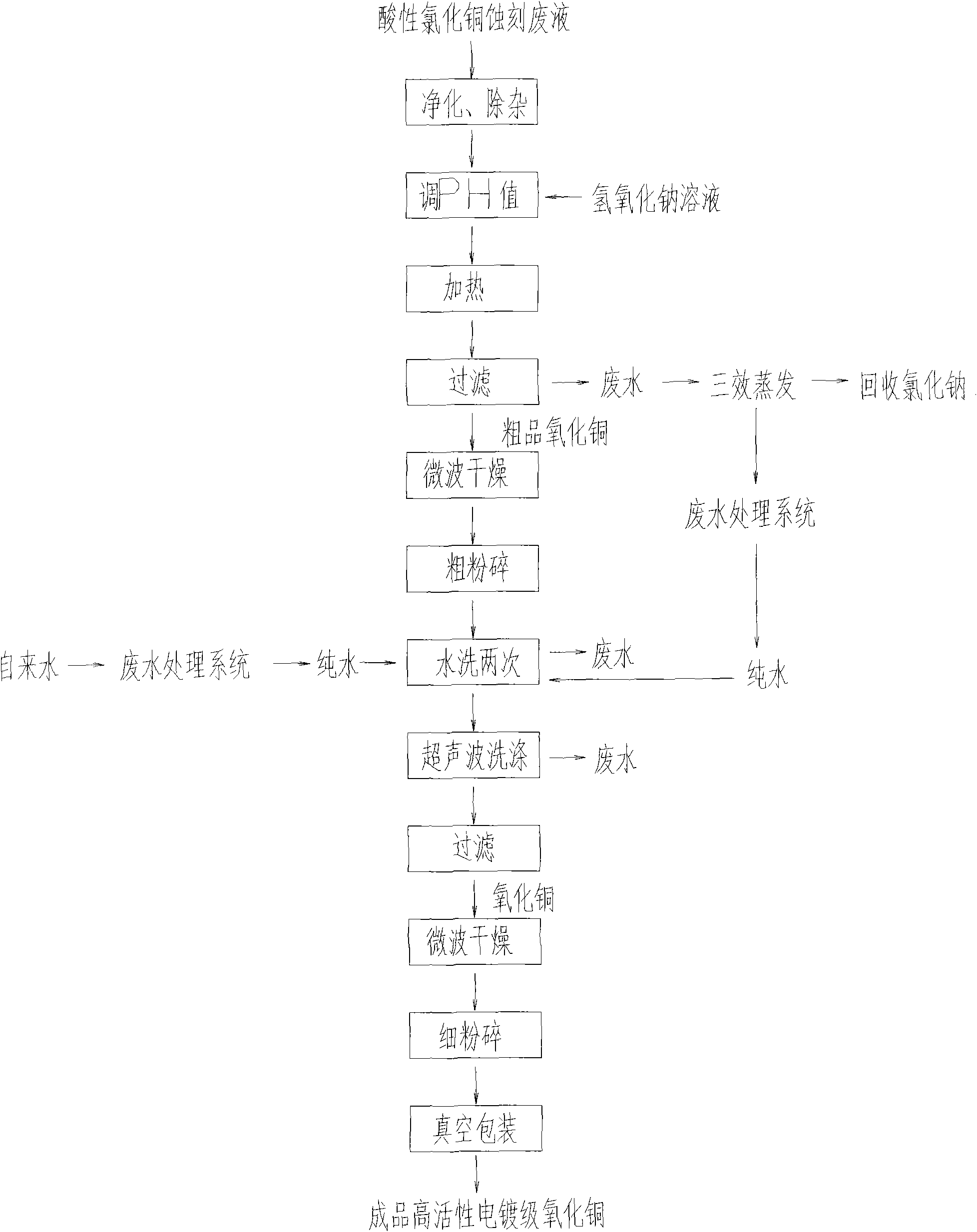

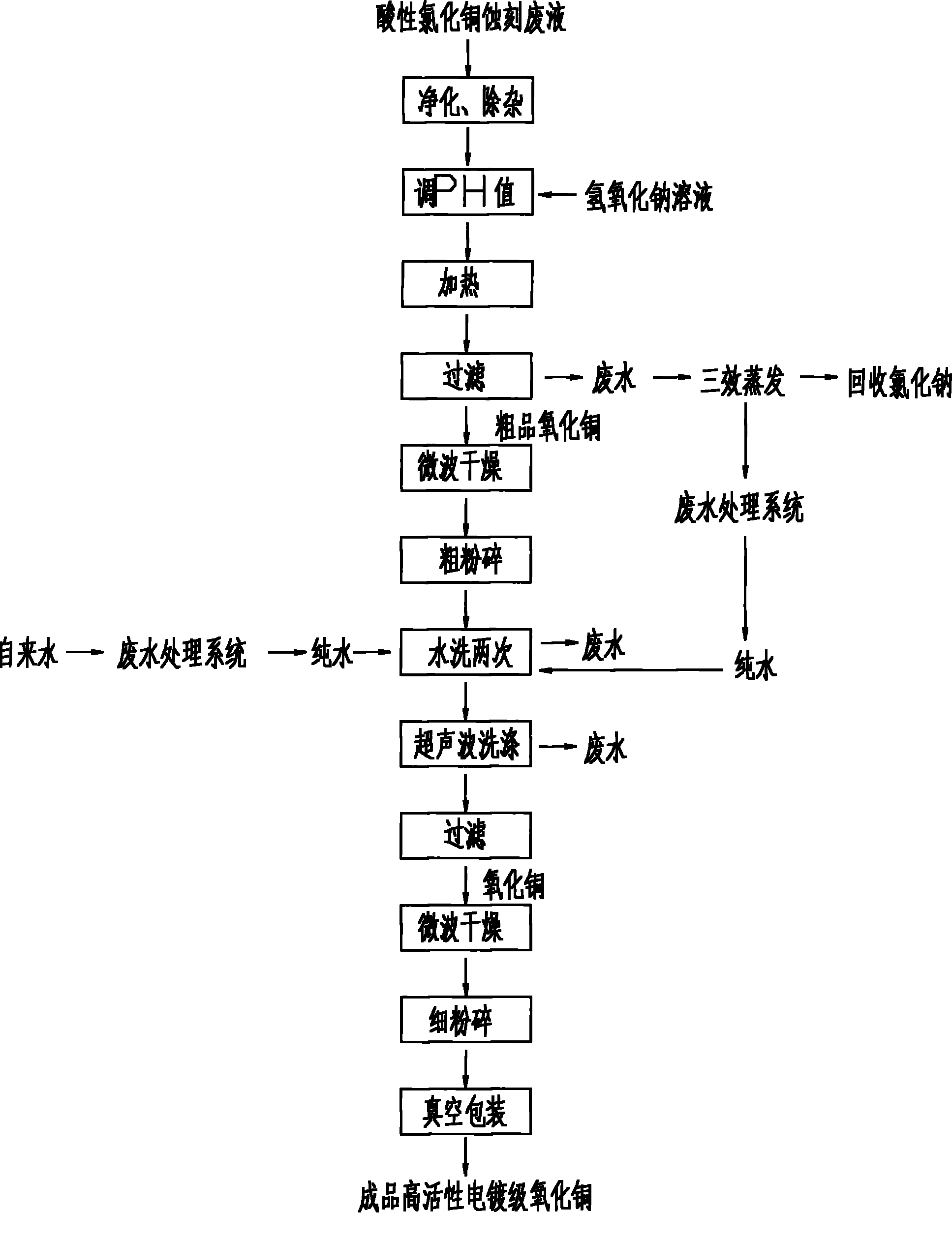

Method used

Image

Examples

Embodiment 1

[0031] The production process with acid copper chloride etching waste liquid and sodium hydroxide as main raw materials is as follows:

[0032] 1. Add 500kg of acidic copper chloride etching waste solution with a copper content of 10% in a 2m3 reactor, add 30% sodium hydroxide solution under stirring, adjust the pH value to 9-13, and open the steam valve to heat , when the temperature reaches 80°C, stop heating and keep it warm for 30-60 minutes; the reactions that occur mainly include:

[0033] h + +OH-=H 2 o

[0034] Cu 2+ +2OH-=Cu(OH) 2

[0035] Cu(OH) 2 =CuO+H 2 o

[0036] 2. Pump the reacted material into the plate and frame filter press for pressure filtration to obtain copper oxide filter cake, and the separated filtrate enters the wastewater treatment system; the process of pressure filtration is a solid-liquid separation process, the purpose is to make the oxidation The separation of copper and liquid is a general process without special requirements; apply t...

Embodiment 2

[0044] The production process with acidic copper sulfate etching waste liquid and potassium hydroxide as main raw materials is as follows:

[0045] 1. At 2m 3 Add 1000KG acidic copper sulfate etching waste liquid with a copper content of 4% to the reaction kettle, add 50% potassium hydroxide solution under stirring, adjust the pH value to 9-13, open the steam valve to heat, when the temperature reaches 100 ℃, stop heating and keep warm for 30-60 minutes, the main reactions are:

[0046] h + +OH - =H 2 o

[0047] Cu 2+ +2OH - =Cu(OH) 2

[0048] Cu(OH) 2 =CuO+H 2 o

[0049] 2. Same as step 2 in Example 1;

[0050] 3. The dried copper oxide enters the pulverizer and pulverizes to 100 mesh;

[0051]4. Transfer the pulverized copper oxide to No. 1 washing bucket, add about 1-2T of pure water, and wash for 20 minutes under stirring;

[0052] 5. Transfer the centrifuged copper oxide into No. 2 washing bucket and repeat the above steps;

[0053] 6. The copper oxide wash...

Embodiment 3

[0057] The production process with acidic copper nitrate etching waste liquid and sodium hydroxide as main raw materials is as follows:

[0058] 1. At 2m 3 Add 800KG acidic copper nitrate etching waste liquid with a copper content of 2% to the reaction kettle, add 10% sodium hydroxide solution under stirring, adjust the pH value to 9-13, open the steam valve to heat, when the temperature reaches 60 ℃, stop heating and keep warm for 30-60 minutes, the main reactions are:

[0059] h + +OH - =H 2 o

[0060] Cu 2+ +2OH - =Cu(OH) 2

[0061] Cu(OH) 2 =CuO+H 2 o

[0062] 2. Same as step 2 in Example 1;

[0063] 3. The dried copper oxide enters the pulverizer and pulverizes to 500 mesh;

[0064] 4. Transfer the pulverized copper oxide to No. 1 washing bucket, add about 1-2T of pure water, and wash for 40 minutes under stirring;

[0065] 5. Transfer the centrifuged copper oxide into No. 2 washing bucket and repeat the above steps;

[0066] 6. The copper oxide washed twic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com