Modified bismaleimide resin as well as preparation method and application thereof

A technology of bismaleimide resin and bismaleimide, which is applied in the direction of plastic/resin/wax insulators, organic insulators, adhesives, etc., can solve problems such as poor paving properties, and achieve low curing temperature and excellent mechanical properties Performance, low viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation modified bismaleimide resin provided by the present invention can specifically carry out by following two methods:

[0022] 1. Melt copolymerization method:

[0023] (1) The reaction vessel is equipped with a reflux condensing device, a thermometer and heating equipment. Add ethynyl aniline to the reaction vessel, heat to 80-120°C, then add or not add a specified amount of thermoplastic toughening agent according to actual needs, keep stirring until the toughening agent is completely dissolved.

[0024] (2) Keep the temperature of the reaction system between 80 and 120°C, add a specified amount of bismaleimide, react at a constant temperature until the resin system is completely dissolved and uniform, and then keep the temperature for 0 to 4 hours to obtain the final modified bismaleimide imide resin.

[0025] 2. Solution copolymerization method:

[0026] (1) The reaction vessel is equipped with a reflux condensing device, a thermometer and heating eq...

Embodiment 1

[0030] The 500ml three-necked bottle is equipped with a reflux condenser, a thermometer and a mechanical stirrer. First add 80g of 4-ethynylaniline, heat to 90°C, then add 40g of polyarylethersulfone with a number average molecular weight of 25,000, and stir at constant temperature until the reaction system is completely dissolved.

[0031] Raise the temperature of the reaction system to 120°C, add 147g of N,N'-diphenylmethane type bismaleimide, react at a constant temperature until the resin system is completely dissolved and uniform, and then keep the temperature for 60 minutes to obtain the modified bismaleimide provided by the present invention imide resin. The resin is a brown-red viscous liquid at room temperature.

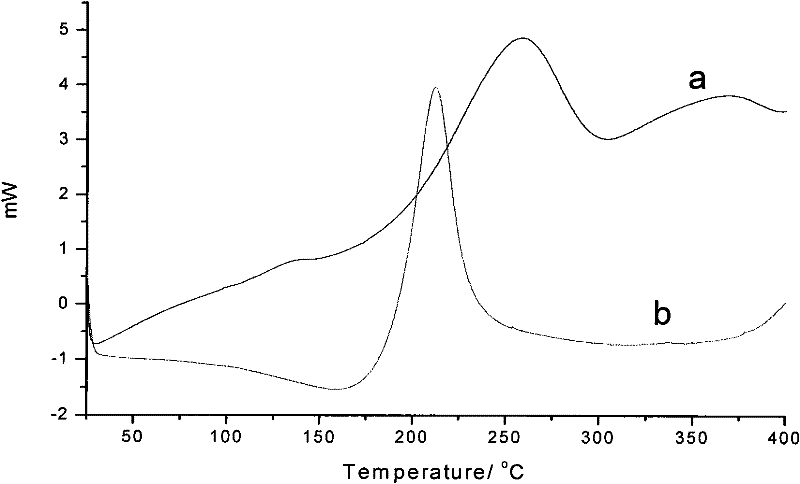

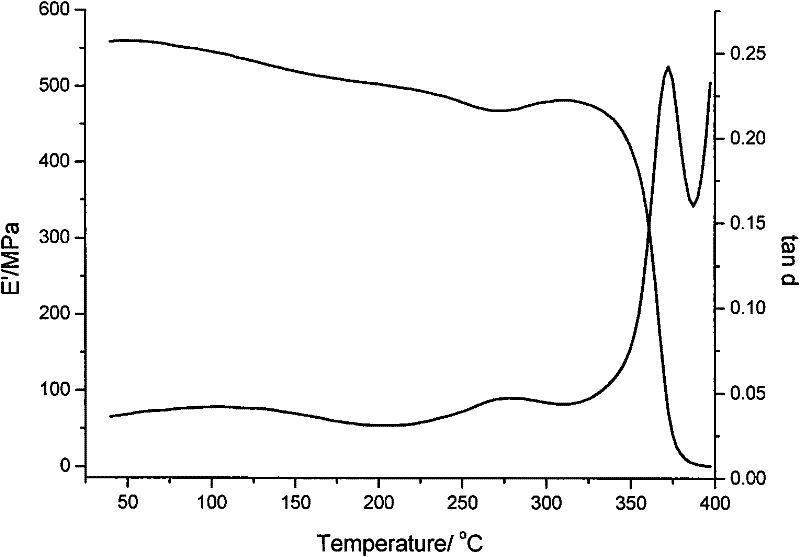

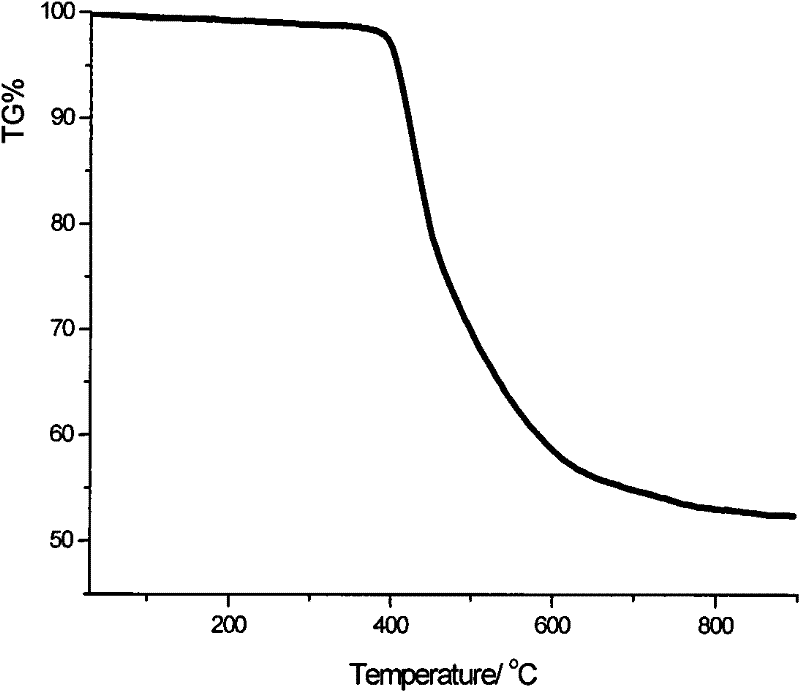

[0032] Characterize the curing behavior of gained modified bismaleimide resin with differential calorimetry scanner (DSC), test atmosphere is N 2 , the heating rate is 10°C / min. figure 1 is the DSC curve of the modified bismaleimide resin. Depend on figur...

Embodiment 2

[0039] The 500ml three-necked bottle is equipped with a reflux condenser, a thermometer and a mechanical stirrer. First add 200g of toluene, then add 20g of 3-ethynylaniline, stir well and heat to toluene reflux temperature. 10 g of polyaryletherketone with a number average molecular weight of 80,000 was added, and the mixture was refluxed until completely dissolved.

[0040] Add 40g of N,N'-diphenyl ether type bismaleimide, reflux reaction until the bismaleimide is completely dissolved, and the resin system is transparent and uniform, then reflux reaction for 6 hours. The solvent in the reaction system was distilled off under reduced pressure, the distillation termination temperature was 90° C., and the vacuum degree was ≥0.096 Mpa to obtain the modified bismaleimide resin provided by the present invention. The resin is a brown-red viscous liquid at room temperature.

[0041] Characterize the curing behavior of gained modified bismaleimide resin with differential calorimetr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com