Low-temperature thermocompression bonding method

A thermocompression bonding, low temperature technology, applied in the manufacture of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problems of high temperature and high pressure, achieve convenient operation, reduce thermal stress and thermal deformation, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

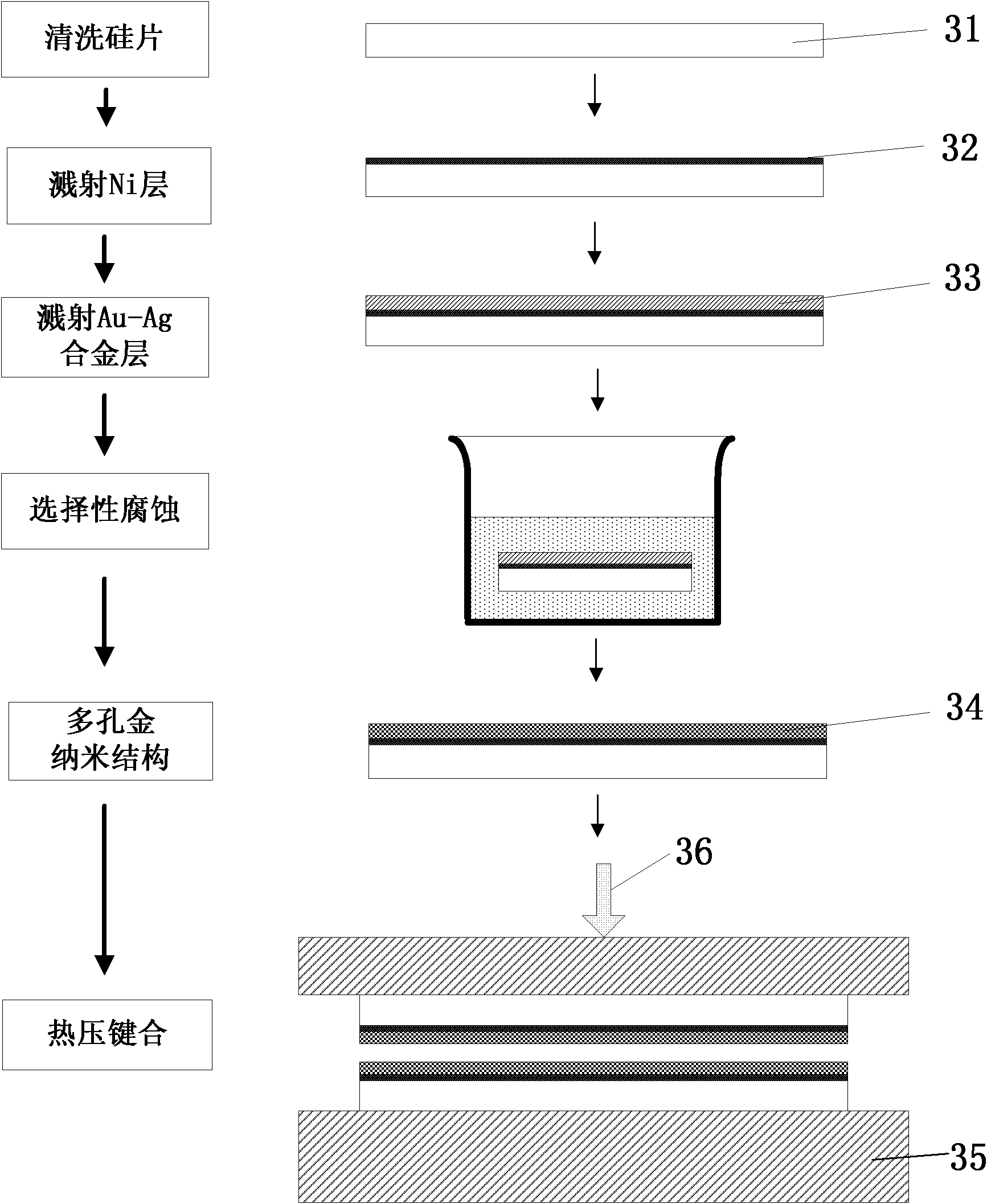

[0020] 1. Use standard RCA process to clean silicon wafer 31, and then deposit Ni layer 32 (30nm) and Au-Ag alloy layer 33 (3μm) on the silicon wafer through sputtering process;

[0021] 2. Put the silicon wafer into 75% HNO 3 In the solution, etch at room temperature for 20 minutes to etch the Ag in the Au-Ag alloy, then wash with deionized water and dry with nitrogen to obtain a porous gold nanostructure layer 34 with a hole size of 20-30 nm on the surface of the silicon wafer;

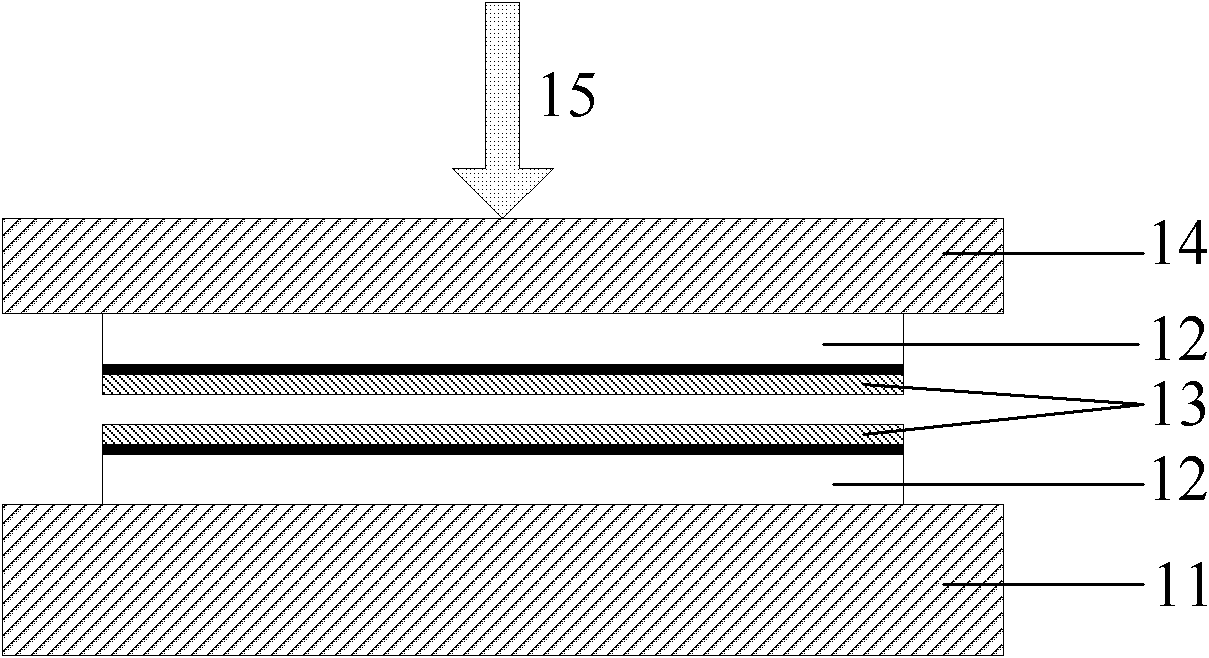

[0022] 3. Place the two silicon wafers with the porous gold nanostructure layer 34 face to face on the hot plate 35, raise the temperature of the hot plate to 150°C, and then apply a pressure of 1 MPa, heat preservation and pressure for 30 minutes, to complete the thermocompression bonding.

Embodiment 2

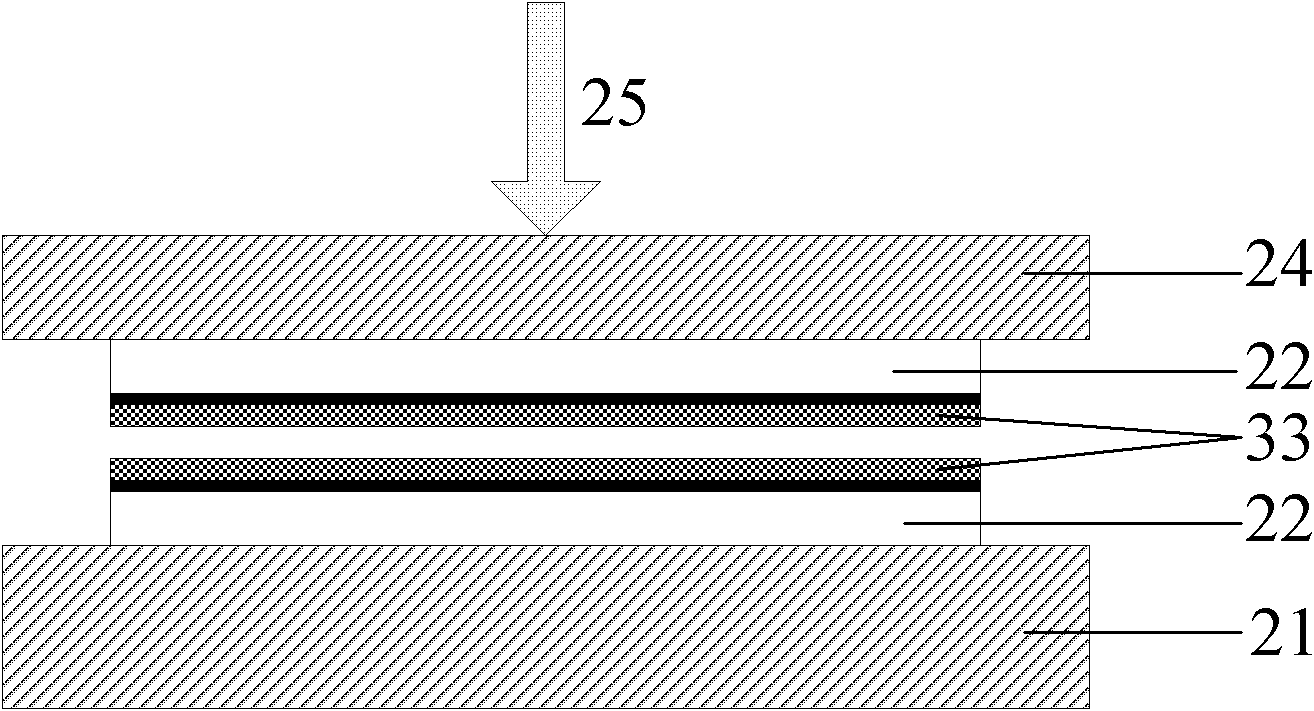

[0024] The process flow of this embodiment is basically the same as that of embodiment 1, except that the alloy layer is changed to a Cu-Al alloy, and a 5% HCl solution is used for corrosion. The bonding temperature is 220°C and the pressure is 5MPa.

Embodiment 3

[0026] 1. Clean the glass sheet 41, and then deposit the Ni layer 42 (30nm) and Cu layer 43 (1μm) on the glass surface through a sputtering process;

[0027] 2. Put the glass sheet with the Cu layer sputtered in a 5% HCl solution for 1 minute to remove surface oxides, then rinse with deionized water, and then put it in the ammonium chloride zinc plating solution. The Zn layer 44 is electroplated on the layer, and the electroplating time is 10 minutes. After electroplating, the glass sheet was cleaned with deionized water, dried with nitrogen, and then placed in an annealing furnace for heat treatment. The annealing temperature was 150°C and the holding time was 2h. The metal Zn and Cu were atomically diffused to obtain Cu- with a thickness of 5μm. Zn alloy layer 45;

[0028] 3. Put the glass sheet with the Cu-Zn alloy layer into 8% NaOH solution and etch for 10 hours to corrode the Zn in the Cu-Zn alloy, then clean it with deionized water and dry it with nitrogen to obtain a hole ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Hole size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com