Continuous cropping resisting biological organic and inorganic compound fertilizer and production method thereof

A bio-organic-inorganic, compound fertilizer technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve problems such as not very obvious effects, and achieve the effects of inhibiting the occurrence of soil-borne diseases, improving utilization, and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

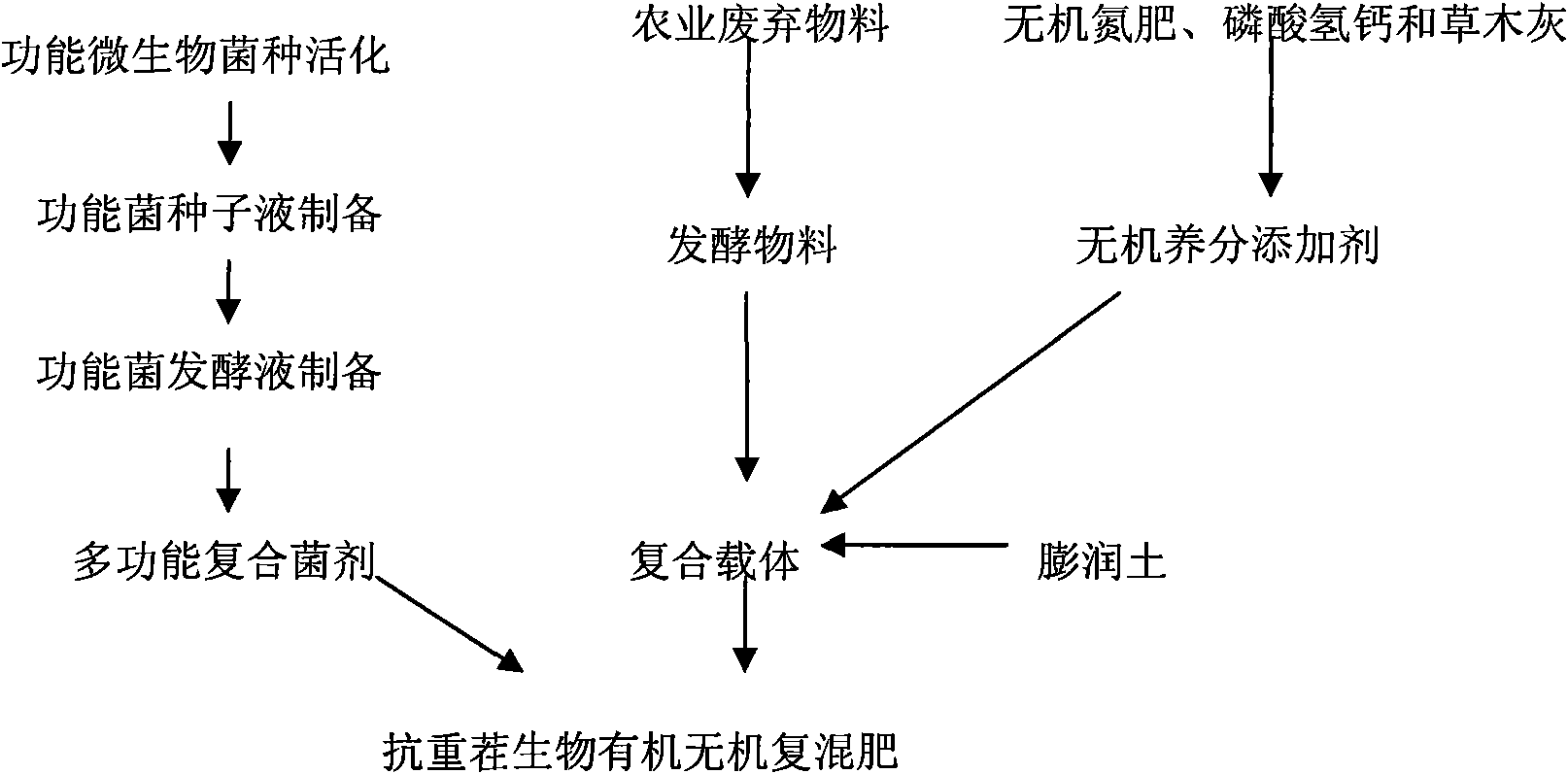

Method used

Image

Examples

Embodiment 1

[0028] The preparation of embodiment 1 compound fertilizer

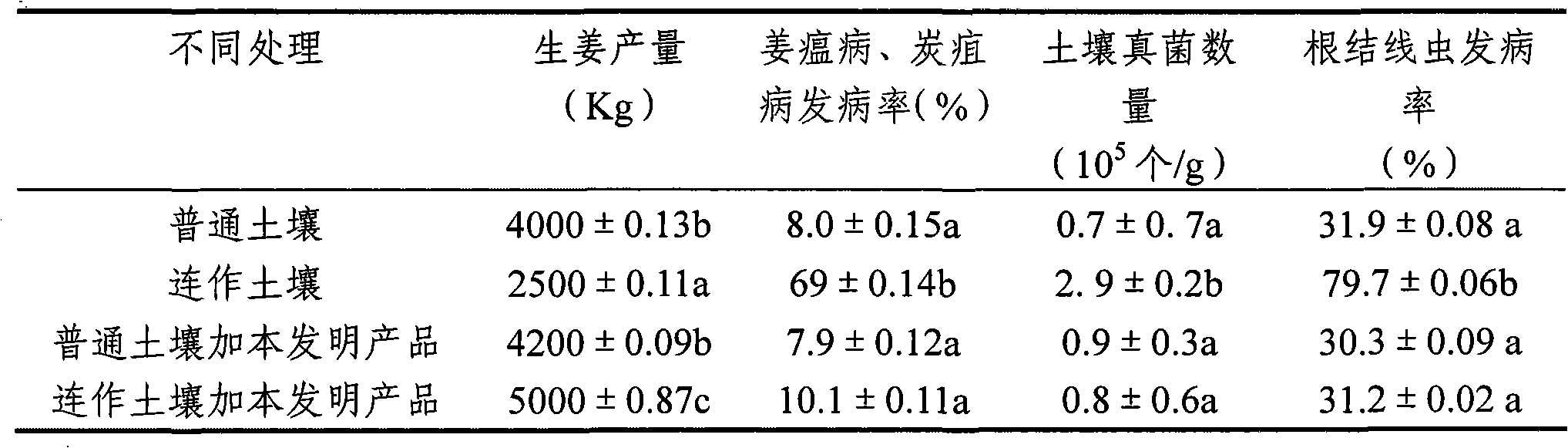

[0029] First, mix cow dung and wheat straw (crushed to 1-2cm) in a weight ratio of 1:2, and ferment aerobically at 60-70°C for about 15 days, and overturn the fermented material 4-5 times every 2-3 days After 15 days, the material began to cool down, and the material was deodorized, sterilized and dried at 60° C. to obtain a fermented material. and inorganic nitrogen fertilizer (urea), calcium hydrogen phosphate and plant ash are mixed according to the mass ratio of 35:20:40 to obtain the inorganic nutrient additive, and then the agricultural waste fermentation material, the inorganic nutrient additive and bentonite are mixed according to the mass ratio of 60:30:10 Mixing and crushing, wherein the fermented agricultural waste material and inorganic nutrient additives are crushed to 180-200 mesh to obtain a composite carrier. Mix the Bacillus subtilis bacteria liquid, Burkholderia bacteria liquid and Bacillus megater...

Embodiment 2

[0030] The preparation of embodiment 2 compound fertilizer

[0031] First, mix corn stalks and livestock bedding in a weight ratio of 1:1, and ferment aerobically at 60-70°C for about 15 days. In the middle, the fermentation materials are turned over 4-5 times every 2-3 days, and the materials start to cool down after 15 days. , the material is deodorized, sterilized and dried at 60°C to obtain a fermented material, and inorganic nitrogen fertilizer, calcium hydrogen phosphate and plant ash are mixed in a mass ratio of 30:25:35 to obtain an inorganic nutrient additive, and then The agricultural waste fermented material, inorganic nutrient additive and bentonite are mixed and crushed at a mass ratio of 55:35:5, wherein the agricultural waste fermented material and the inorganic nutrient additive are crushed to 180-200 mesh to obtain a composite carrier. Mix the Bacillus subtilis liquid, the Burkholderia bacteria liquid and the Bacillus megaterium liquid in a volume ratio of 15:...

Embodiment 3

[0032] The preparation of embodiment 3 compound fertilizer

[0033] First, the agricultural organic waste materials are fermented, deodorized, sterilized, and dried at high temperature, and the fermented materials mainly include farmland and orchard residues, livestock and poultry excrement, corral litter, and agricultural product processing waste. Aerobic fermentation at 60-70°C for about 15 days, during which the fermented material was turned over 4-5 times every 2-3 days, and the temperature of the material began to drop after 15 days, and the material was deodorized, sterilized and dried at 60°C. The fermentation material is obtained, and the inorganic nitrogen fertilizer, calcium hydrogen phosphate and plant ash are mixed in a mass ratio of 40:15:35 to obtain an inorganic nutrient additive, and then the agricultural waste fermentation material, the inorganic nutrient additive and bentonite are mixed in a mass ratio of 65:25 : 10 mixed and pulverized, wherein the fermented...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com