Rubber-metal bonding enhancer for steel wire radial tyre and preparation method thereof

A radial tire and metal bonding technology, which is applied in the field of rubber additives, can solve the problems of affecting the physical and chemical properties and use performance of products, insufficient reactivity of weak organic acids, and affecting the bonding performance of products, so as to solve the problem of unstable synthesis reaction , Solve the loss of acid water solubility, the effect of normal and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

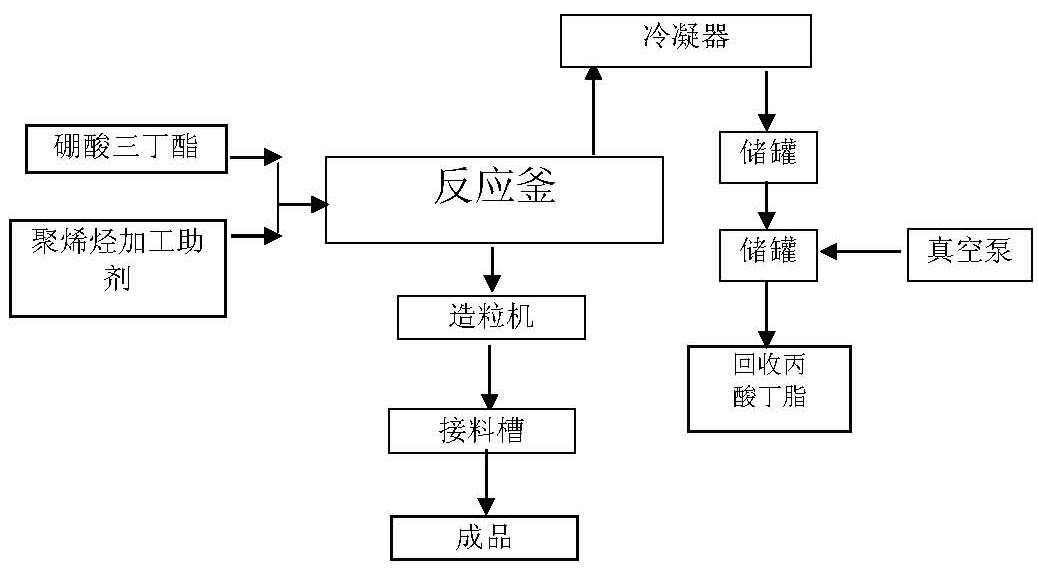

Method used

Image

Examples

Embodiment 1

[0077] According to the proportioning preparation under the item of embodiment 1 in table 1, the low-cobalt boroacylated metal compound salt is prepared as follows:

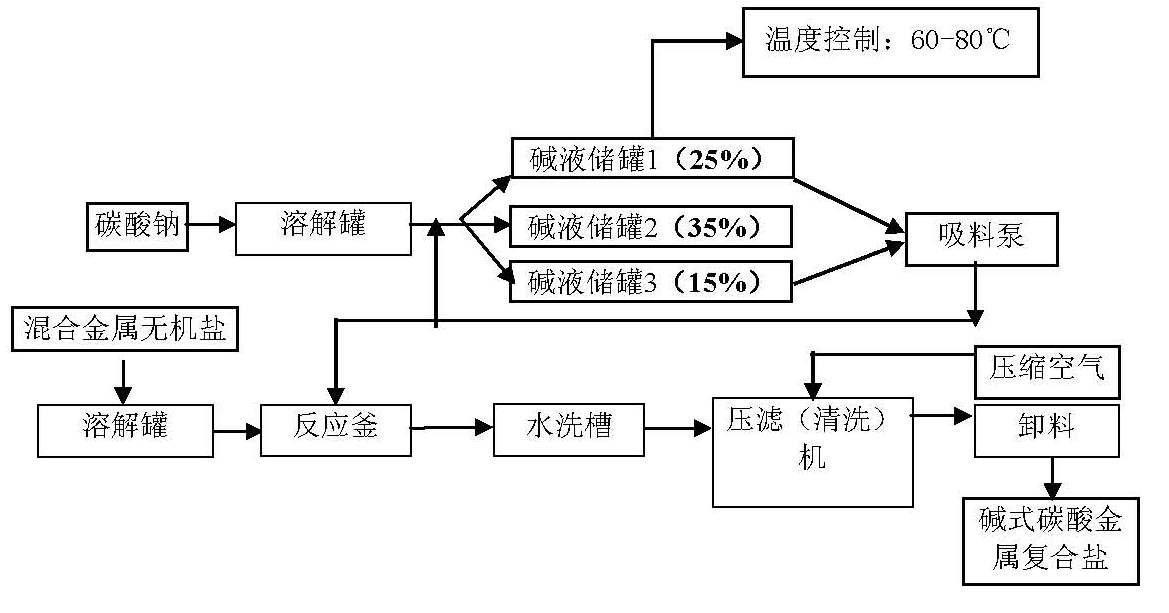

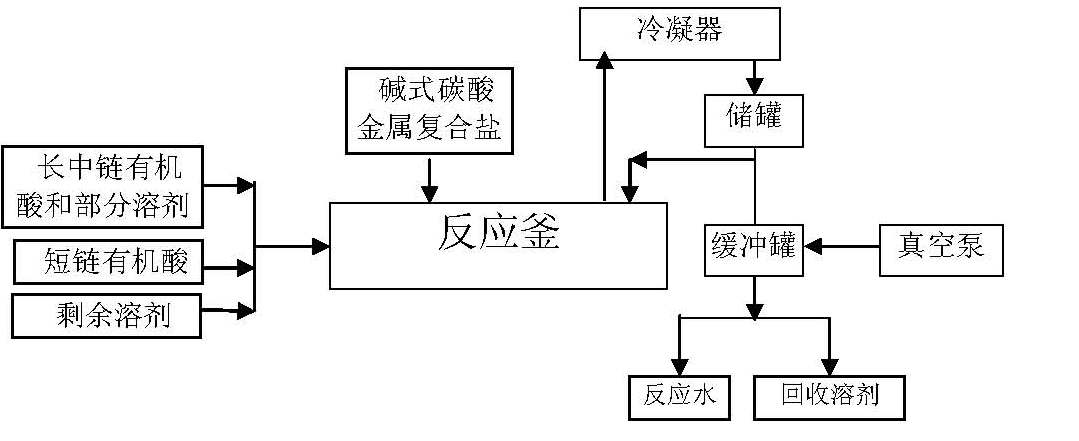

[0078] (1) Production of basic metal carbonate compound salt by temperature gradient method and concentration step method

[0079] A. Dissolve sodium carbonate at 80°C into solutions with concentrations of 15%, 25%, and 35%, respectively.

[0080] Put into the different storage tanks of heat preservation for standby, the temperature of sodium carbonate solution is kept between 60-80 ℃ in the reaction process;

[0081] B. Dissolve cobalt sulfate, nickel sulfate, copper sulfate and zinc sulfate in water into a solution with a concentration of 35%, place it in a reaction kettle, heat up at a rate of 5°C / h under continuous stirring, and start adding at 55°C The pump atomizes the sodium carbonate solution with a concentration of 25%, and gradually raises the temperature to 70°C at a rate of 5°C / h, and controls the pH...

Embodiment 2

[0088] Prepare raw materials according to the proportioning under embodiment 2 in table 1, metal adopts sulfate, low cobalt boroacylated metal compound salt

[0089] Prepare as follows:

[0090] (1) Production of basic metal carbonate compound salt by temperature gradient method and concentration step method

[0091] A. Dissolve sodium carbonate at 75°C into solutions with concentrations of 15%, 25%, and 35%, respectively.

[0092] Put into the different storage tanks of heat preservation for standby, the temperature of sodium carbonate solution is kept between 60-80 ℃ in the reaction process;

[0093] B. Dissolve cobalt sulfate, nickel sulfate, copper sulfate and zinc sulfate in water into a solution with a concentration of 25%. The pump atomizes the sodium carbonate solution with a concentration of 25%, and gradually raises the temperature to 70°C at a rate of 5°C / h, and controls the pH to 7.0. When the pH value reaches 7.0, add a 35% sodium carbonate solution atomized by...

Embodiment 3

[0100] According to the proportioning preparation under embodiment 3 item in table 1, metal adopts chloride salt, low cobalt boroacylated metal compound salt

[0101] The preparation method is the same as in Example 1.

[0102] The physical and chemical index test results of the product obtained in this embodiment are shown in Table 2, the use index test results are shown in Table 3, and the cost analysis is shown in Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com