Microbial strain capable of hydrolyzing 3-hydroxybutyronitrile

A technology of hydroxybutyronitrile and microorganisms, which is applied in the field of microorganisms, can solve problems such as insoluble in water, influence research, and high price, and achieve high industrial production potential, mild reaction conditions, and less hydrolysis by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

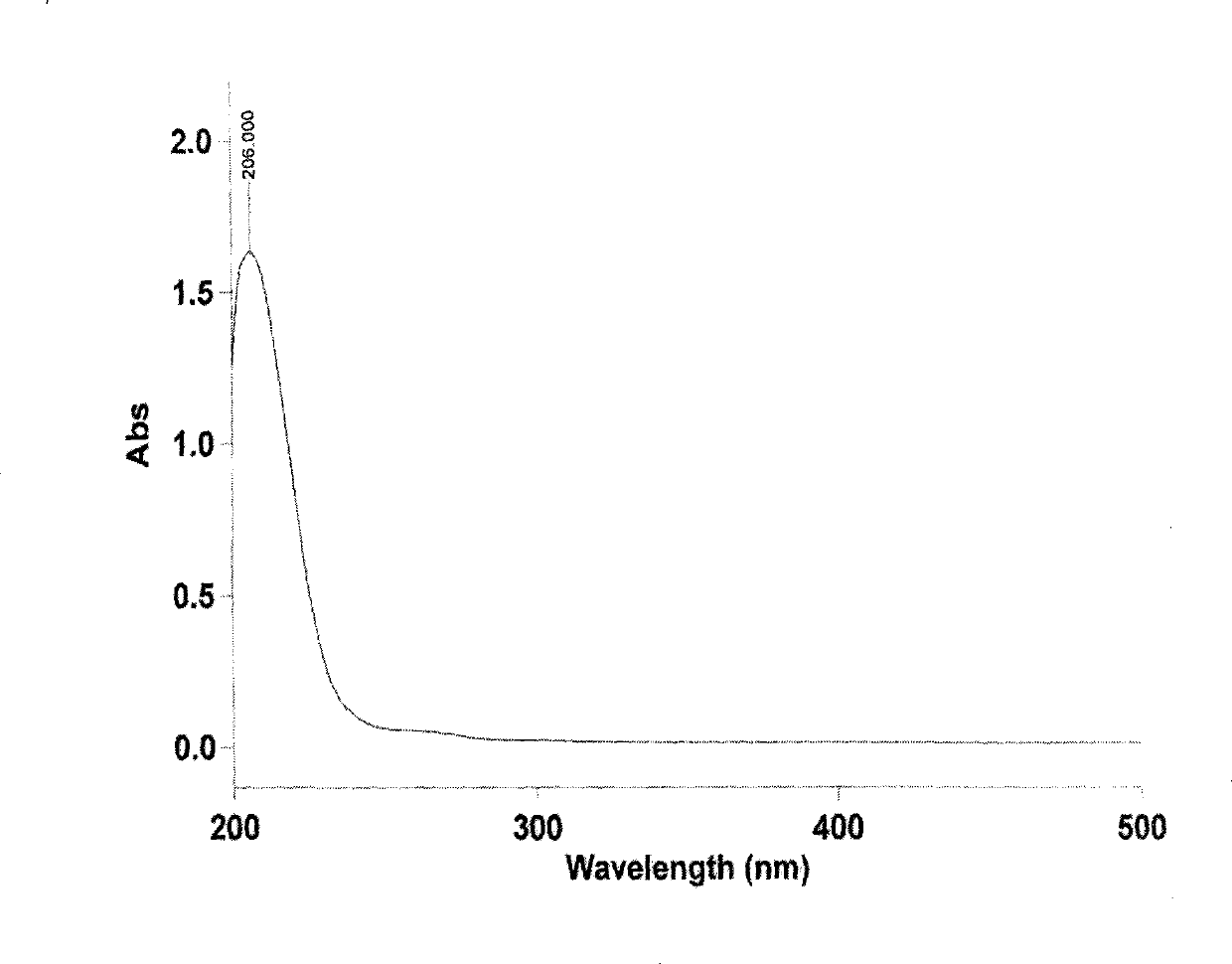

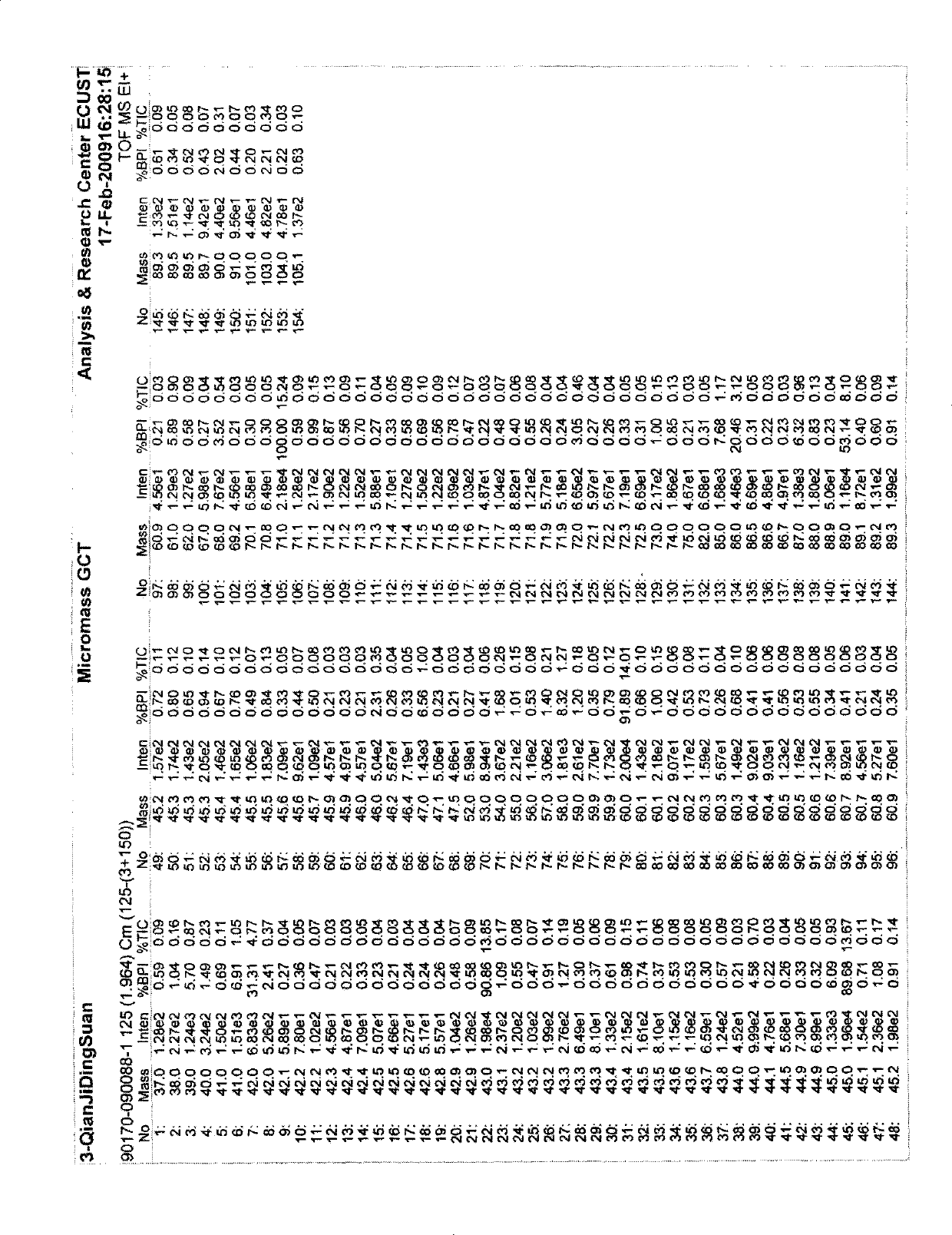

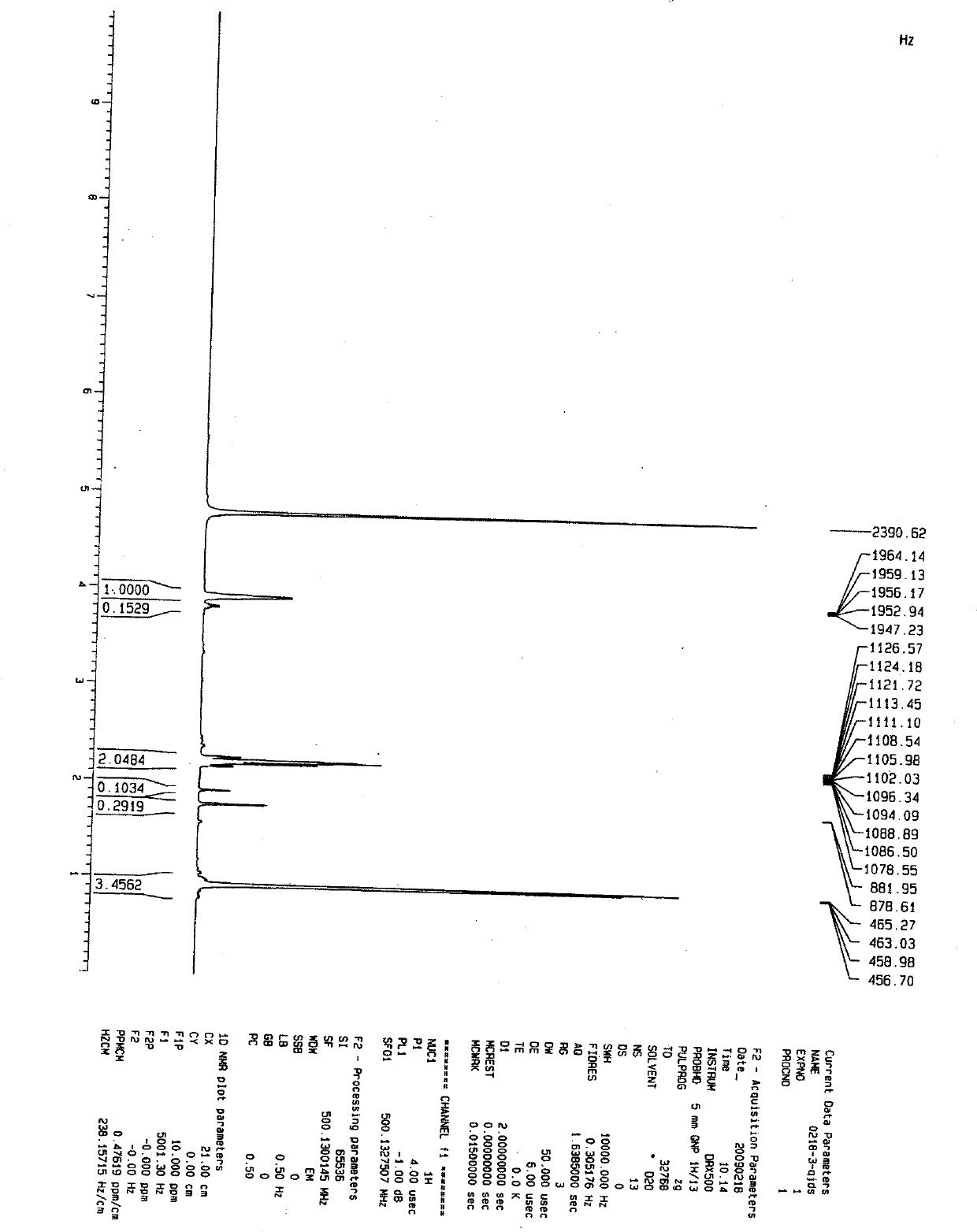

Image

Examples

Embodiment 1

[0045] Example 1 , Preparation of slant medium

[0046] The slant medium was prepared according to the formula shown in Table 1 to obtain slant medium 1-5.

[0047] Table 1, slant medium formula (wt%)

[0048]

Embodiment 2

[0049] Example 2 , Preparation of fermentation medium

[0050] Fermentation media were prepared according to the formulations shown in Table 2 to obtain fermentation media 1-5.

[0051] Table 2, fermentation medium formula (wt%)

[0052]

Embodiment 3

[0053] Example 3 , Arthrobacter nitroguajacolicus CGMCC No.2405 fermentation culture

[0054] Arthrobacter nitroguajacolicus CGMCC No.2405 was respectively inoculated onto the slant medium 1-5 prepared in Example 1, and cultured at 28°C for 3-4 days to obtain the culture slant 1-5.

[0055] Then, Arthrobacter nitroguajacolicus CGMCC No.2405 was picked from the culture slope 1-5 and inoculated into the fermentation medium 1-5 prepared in Example 2, and cultured at 28° C. and 220 rpm for 4 days to obtain fermentation broth 1-5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com