Treatment method realizing polymer-bearing produced wastewater resource utilization

A treatment method and technology for water resources, applied in mining wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. effect, realizing the effect of resource utilization and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

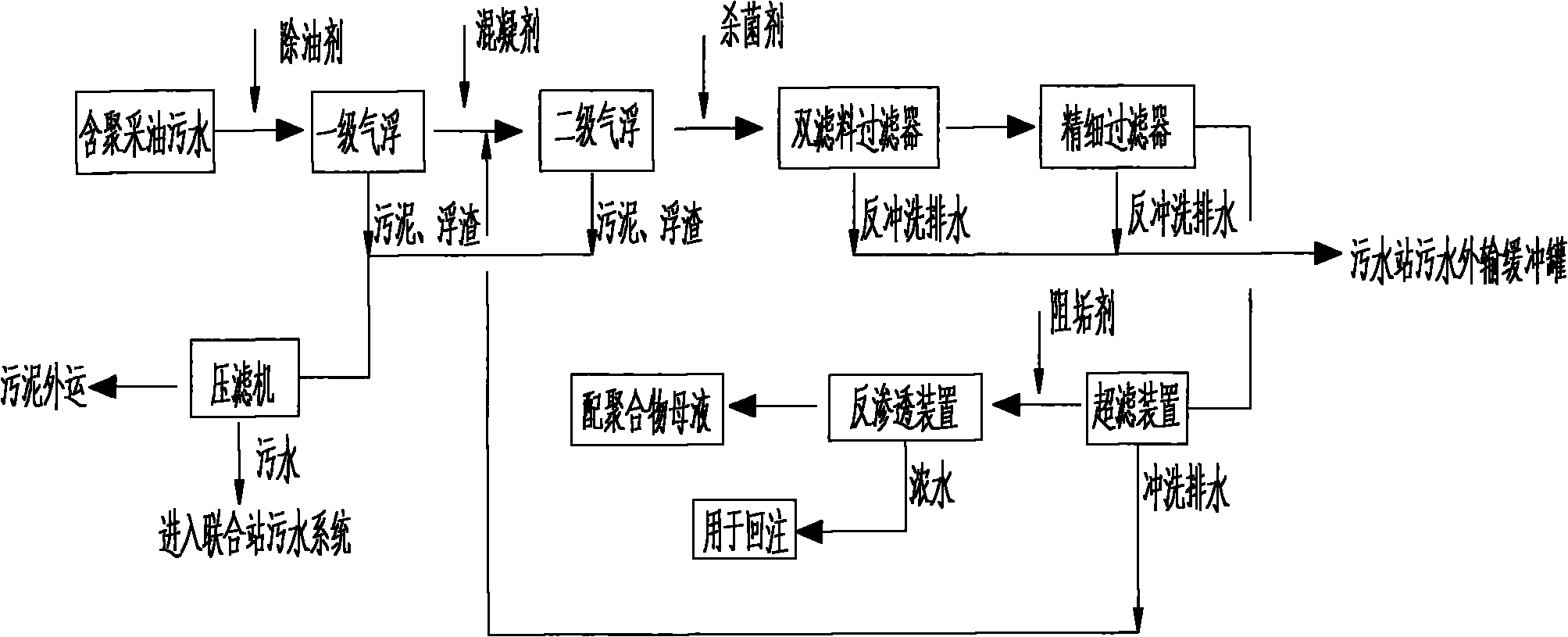

[0011] Embodiment 1, combining figure 1 In the middle (part), the pretreatment stage adopts the treatment process of two-stage air flotation + double filter material filter + fine filter, and the chemicals added mainly include degreasing agent, coagulant, fungicide, lye, etc. The amount of dosing is based on the water intake of 120m 3 Calculation per hour, degreasing agent is added to the inlet of the first-stage air flotation. , such as: inorganic salt coagulant (aluminum sulfate), inorganic polymer salt (polyaluminum chloride), organic polymer coagulant (polyacrylamide), the dosage is 300-500mg / L, continuous dosage Add; Dosing lye (NaOH) at the inlet of the two-stage filter backwash pump, the commonly used volume concentration is 5%-10%, the dosage is 2.0-3.0mg / L, intermittent dosing, 1 time / month. Dosing fungicides at the inlet of the double filter material filter, commonly used fungicides include chlorine dioxide, quaternary ammonium salts, glutaraldehyde, halogenated ph...

Embodiment 2

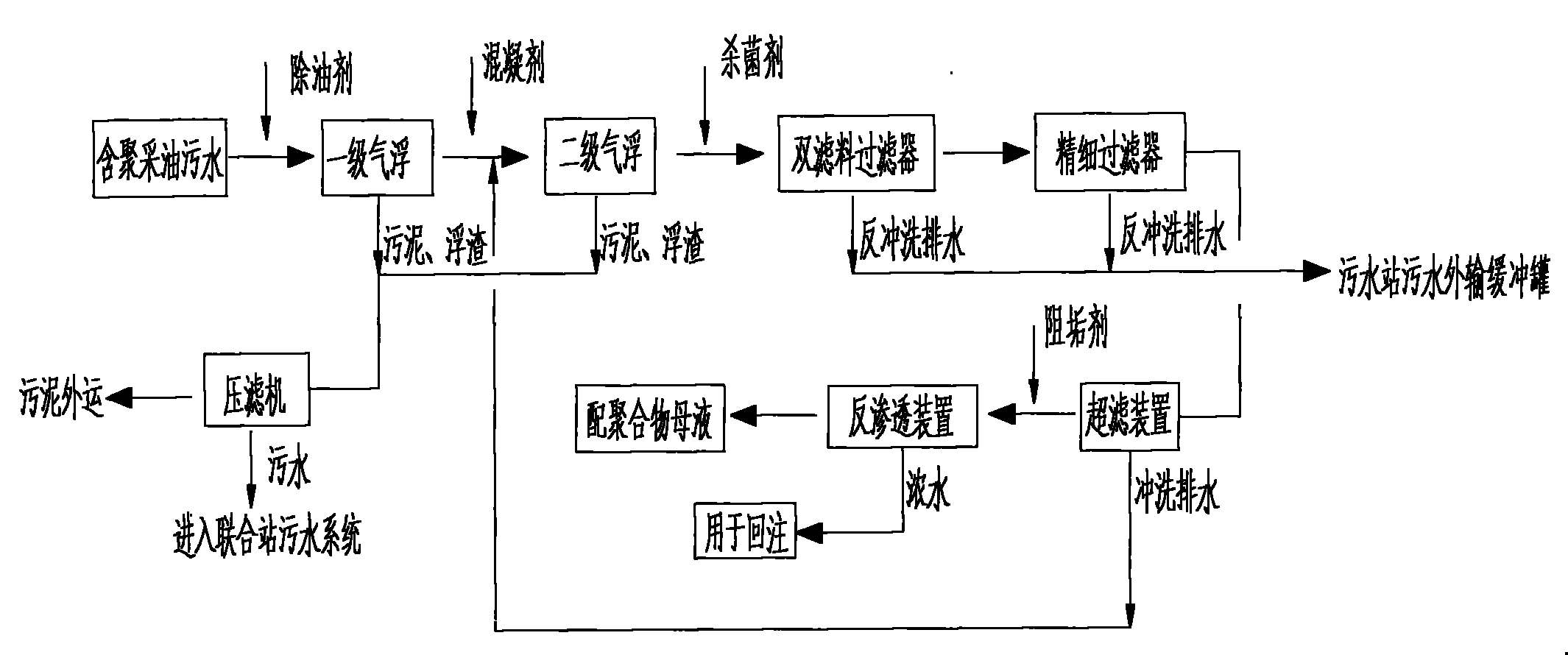

[0013] Example 2, combined with figure 2 (All), on the basis of Example 1, the reuse of filter backwash water and ultrafiltration concentrated water is considered in the auxiliary system, and the filter backwash water is discharged to the secondary air flotation equipment and circulated in the system Treatment reduces the cost of water production and sewage discharge, and considers the disposal of pretreated sludge and scum.

[0014] In the technical solutions of the above two embodiments, many specific examples can be combined after arbitrarily selecting the medicament and the limited dosage, all of which can better achieve the purpose of the present invention.

Embodiment 3

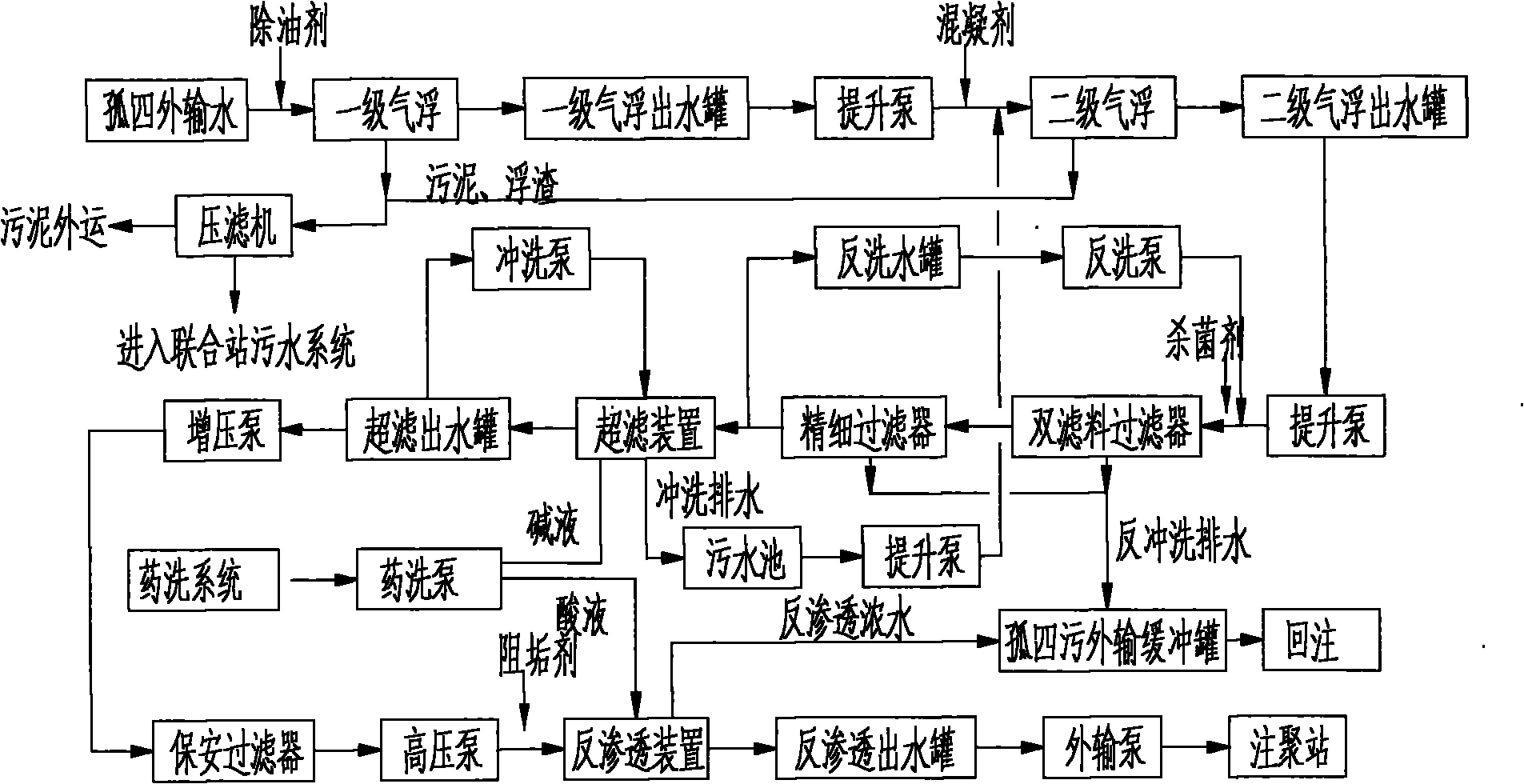

[0015] Example 3, combined with figure 2 , the advanced treatment and comprehensive utilization pilot project of the isolated four pollutants, the complete process flow has been given in the accompanying drawings, combined with the medicament and dosage given in the above Example 1, it constitutes a more complete treatment method, no longer Do a text description. The project processing scale: product water 1000m 3 / d (for preparing polymer mother liquor), concentrated water 1000m 3 / d (for reinjection) to reach full capacity.

[0016] The input amount of the present invention is relative to the amount of sewage treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com