Method for removing heavy metals in excess sludge by bioleaching-similar Fenton oxidative coupling

A technology of biological leaching and excess sludge, which is applied in biological sludge treatment, oxidation treatment of sludge, chemical instruments and methods, etc., can solve the problems of difficult application, high operating cost of sludge treatment, and long biological leaching period. , to achieve the effect of short process flow, low content of toxic and harmful substances and pathogens in sludge, and good dewatering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

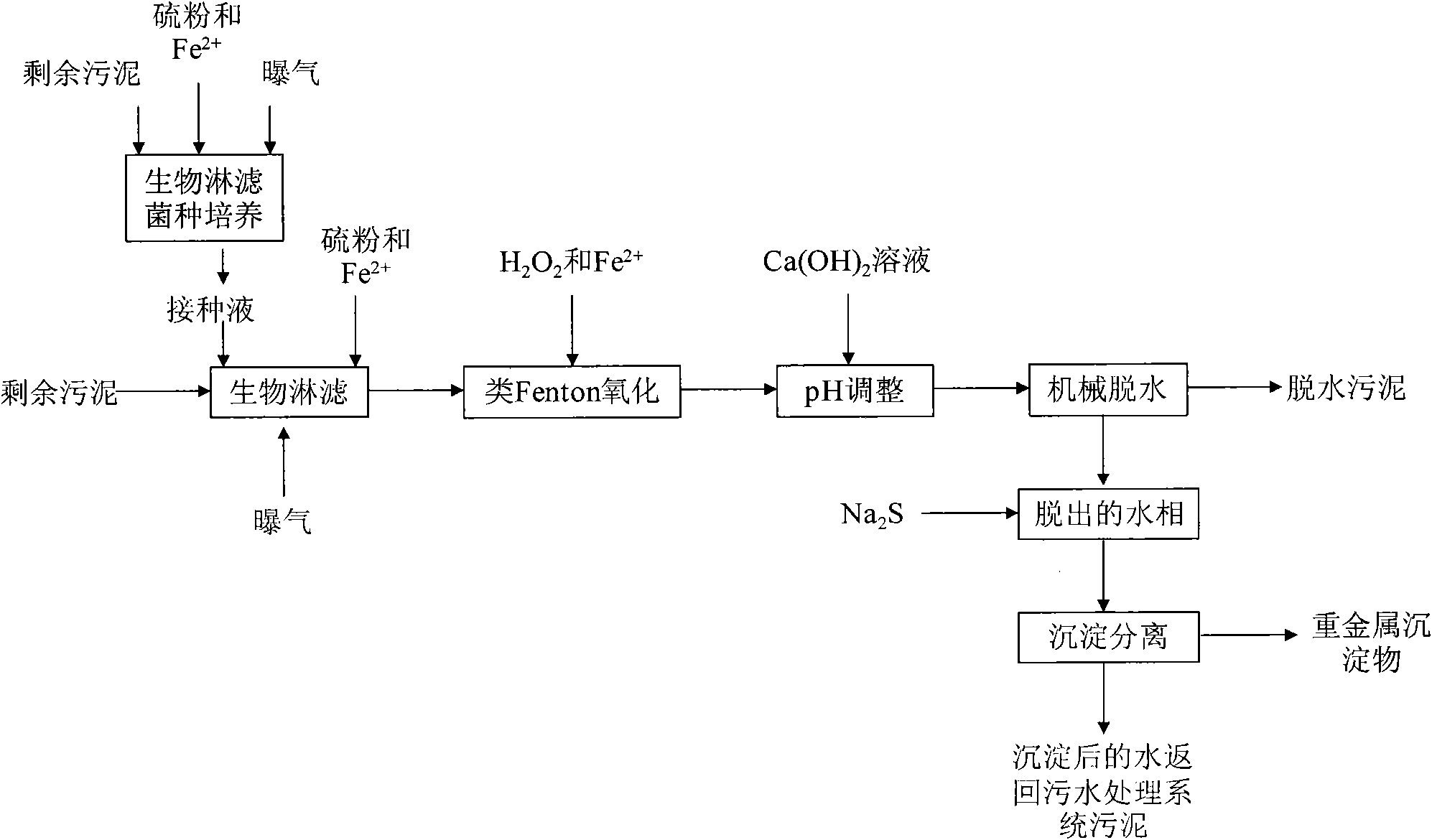

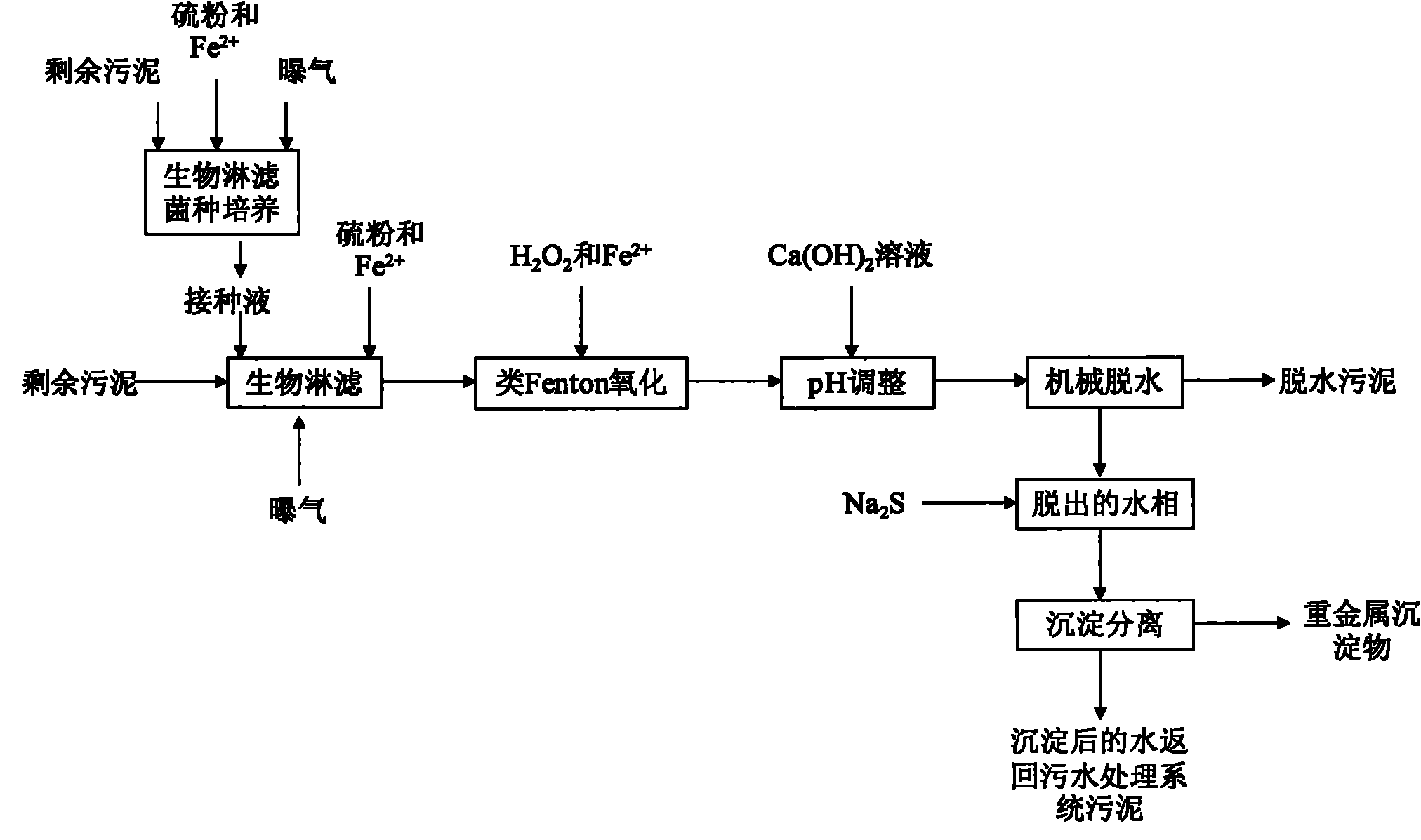

[0022] This process is used for batch treatment of sludge in the laboratory. The treated sludge is the residual sludge produced by the oxidation ditch process to treat urban domestic sewage. The main characteristics of the sludge are: pH, 6.83; total solid content, 14461mg / L; volatile solid content, 10048mg / L; copper content, 421mg / L kg dry sludge; zinc content, 1512mg / kg dry sludge; lead content, 177mg / kg dry sludge; cadmium content, 13.7mg / kg dry sludge; chromium content, 258mg / kg dry sludge: arsenic content, 2.3 mg / kg dry sludge; nickel content, 59.9mg / kg dry sludge. Specific processing steps refer to figure 1 :

[0023] (1) Sludge bioleaching inoculum cultivation: The inoculum cultivation and domestication process uses concentrated sludge with a solid content of 2% from the oxidation ditch process. Take 100mL of sludge in a 250mL Erlenmeyer flask, add 10g / L of S powder and 10g / L of FeSO 4 ·7H 2 O, shake culture at 180r / min at 28°C until the pH of the sludge drops belo...

Embodiment 2

[0029] This process is used to expand the pilot scale treatment of sludge. The treated sludge is A 2 The remaining concentrated sludge after treatment of urban domestic sewage by / O process, the main characteristics of the sludge are: pH, 7.10; total solid content, 25660mg / L; volatile solid content, 20185mg / L; copper content, 299mg / kg dry sludge ; Zinc content, 2108mg / kg dry sludge; Lead content, 87.7mg / kg dry sludge; Cadmium content, 5.7mg / kg dry sludge; Chromium content, 48.5mg / kg dry sludge; Nickel content, 47.4mg / kg kg of dry sludge. Specific processing steps refer to figure 1 :

[0030] (1) Sludge bioleaching inoculum culture: In 5L sludge with a solid content of 2.5%, add sulfur powder and FeSO at 10 and 20g / L respectively 4 ·7H 2 O is used as an energy source for leaching bacteria, air is blown from the bottom of the reactor at 0.5 L / (min·L sludge), and the domesticated sludge is cultivated at 28 °C and 180 r / min under agitation until the pH of the sludge drops to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com