Method for preparing modified betaine type amphoteric surfactant used for tertiary oil recovery

A surfactant and surface active technology, applied in the direction of sulfonate preparation, chemical instruments and methods, drilling compositions, etc., can solve the problem of affecting the surface tension of the solution, the active agent molecules cannot be closely arranged, salt resistance, and high temperature resistance Unsatisfactory performance and other problems, to achieve the effect of high interface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

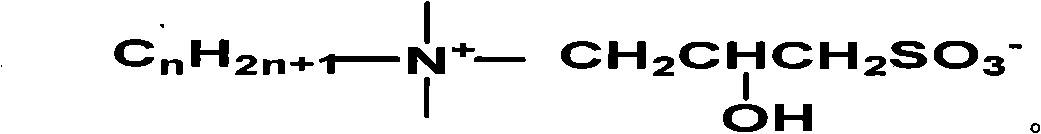

[0013] The preparation method of the alkylhydroxy sultaine type amphoteric surfactant for tertiary oil recovery of the present invention is to use sodium bisulfite, epichlorohydrin, and long-chain alkyl tertiary amine as raw materials, through ring-opening reaction, quaternary The ammonification reaction makes the alkyl hydroxy sultaine type amphoteric surfactant, and the preparation steps are as follows:

[0014] (1) Preparation of 3-chloro-2-hydroxypropanesulfonate sodium: NaHSO 3 Dissolve in water, and slowly add equimolar epichlorohydrin to it when the temperature rises to 40°C. After the addition was completed and the reaction was continued for 7 hours, white crystals were precipitated by cooling, which were spin-dried with a rotary evaporator to obtain 3-chloro-2-hydroxypropanesulfonate sodium crystals;

[0015] (2) Salt formation: the 3-chloro-2-hydroxypropanesulfonate sodium prepared in step (1) and the long-chain alkyl tertiary amine are dissolved in methanol at a ra...

Embodiment 1

[0022] Fully dissolve 0.3 mol of sodium bisulfite in 50 mL of distilled water. When the temperature rises to 40°C, slowly drop in equimolar epichlorohydrin with a dropping funnel, and finish the reaction after 7 hours of reaction. The ring opening reaction produces sodium 3-chloro-2-hydroxy-propanesulfonate.

[0023] Add 1-1.5Ml of long-chain alkyl tertiary amine and 60ML of methanol solvent into the flask containing the above product, heat to reflux at 90°C for 8h, and end the reaction to obtain the target product. Three experiments were performed in parallel, and the obtained products could make the oil-water interfacial tension reach ultra-low.

Embodiment 2

[0025] Get prepared alkyl hydroxy sultaine surfactant 0.4g, water 99.6g, carry out interfacial tension measurement experiment with Shengli Gudong crude oil, Gudao crude oil and Shengtuo crude oil respectively, from the experimental result, the active agent of research and development Good universality, oil-water interfacial tension can reach ultra-low (10 -3 mM / m), has good heat and salt resistance, calcium and magnesium resistance. The water used in the experiment was Gudong Dongsanlian injection water (its salinity is 10428mg / L, and the concentration of calcium and magnesium ions is 330mg / L). (The salinity is 8618mg / L, the concentration of calcium and magnesium ions is 189mg / L), the crude oil is the crude oil of 2N3 well; ), the crude oil is crude oil from well 5-5; Shengtuo six station water (its salinity is 17435mg / L; calcium and magnesium ion concentration is 475mg / L), crude oil is crude oil from well 2-4-N251.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com