Metal-base film thermocouple and preparation method thereof

A production method and technology of thermocouples, applied in thermoelectric device components, manufacturing/processing of thermoelectric devices, thermometers using electric/magnetic elements directly sensitive to heat, etc., can solve the problem of affecting measurement accuracy, consistency and reliability Poor performance, large insulation layer thickness and other problems, to achieve the effect of improving consistency and reliability, reliable design basis, and improving insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

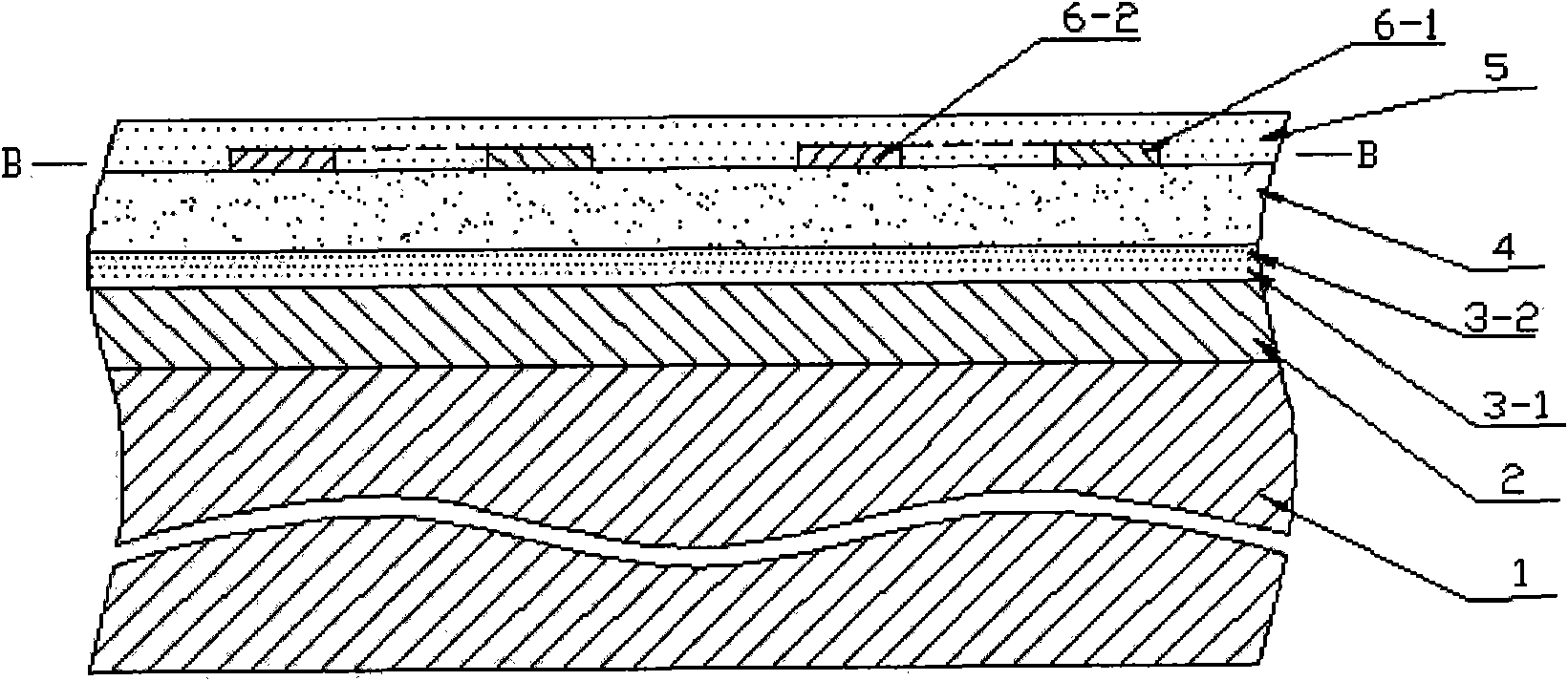

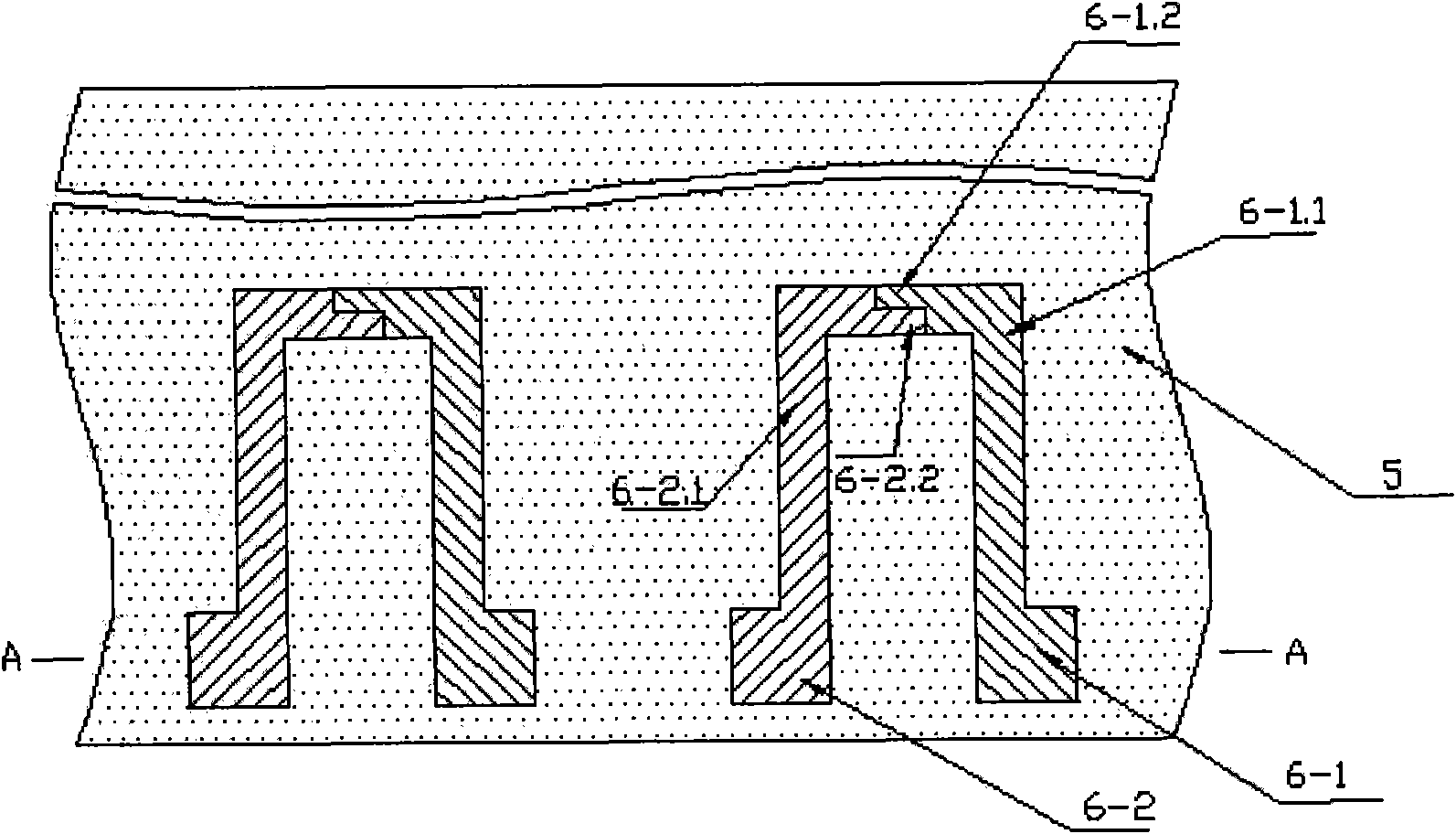

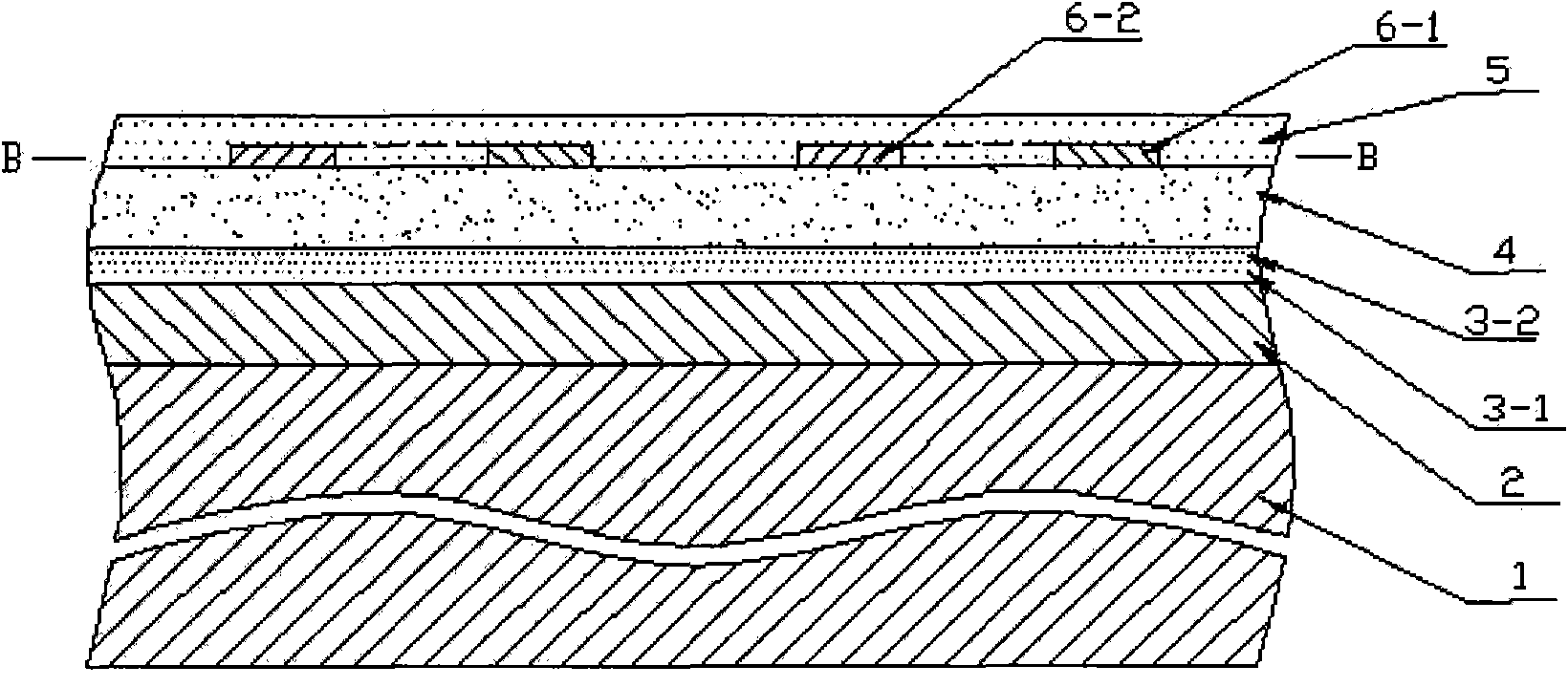

[0020] Take the K-type NiCr-NiSi thermocouple film sensor prepared on a nickel (Ni)-based alloy substrate as an example:

[0021] 1) A nickel (Ni)-based alloy of (length×width×thickness) 30×95×5 mm was used as the substrate 1 to be tested, and after being ultrasonically cleaned with acetone and ethanol in sequence, it was dried under a nitrogen atmosphere;

[0022] 2) Put the cleaned Ni-based alloy substrate 1 in a vacuum of 6.0×10-4 In Pa vacuum (i.e. background vacuum) environment, NiCrAlY alloy is used as the target material, and argon gas with a purity of 99.999% is input as the sputtering medium at a temperature of 600°C, a power of 200W, and a sputtering pressure (working pressure) of 0.5Pa Under the condition of , the NiCrAlY alloy is deposited on the Ni-based alloy substrate by the DC magnetron sputtering method, and the deposition thickness is 10 μm, so as to obtain a composite substrate covering the NiCrAlY alloy transition layer 2;

[0023] 3) Put the composite subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com