Solid lubricating oil additive MoSe2 nanosheet and preparation method thereof

A technology of lubricating oil additives and nanosheets, applied in the direction of additives, nanostructure manufacturing, nanotechnology, etc., can solve the problems of environmental pollution, complex process control, etc., and achieve the effect of low price, easy control of parameters, and good crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: Preparation of solid lubricating oil additive MoSe 2 Nanosheets

[0015] Weigh molybdenum powder (purity 99%) and selenium powder (purity 99.9%) according to the molar ratio of 1:3, mix the two and grind evenly with agate mortar, put into stainless steel reactor; In the furnace, raise the temperature in the furnace to 750°C at a heating rate of 10°C / min, and keep it for 1h; let the temperature in the high-temperature box-type furnace cool down to room temperature naturally (about 5h), and open the reaction kettle to see the dark brown powder It is the solid lubricating oil additive MoSe 2 Nanosheets.

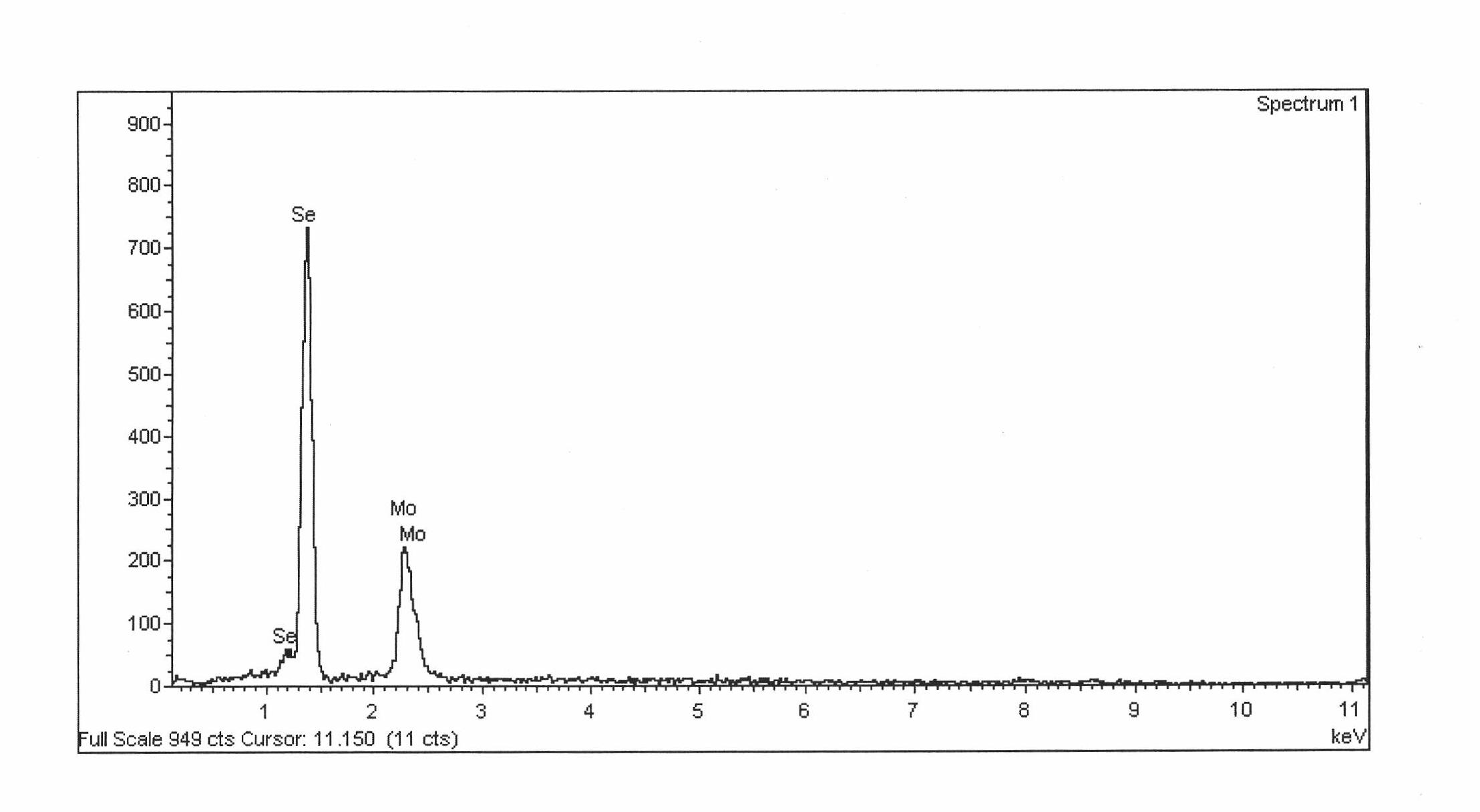

[0016] To the solid lubricating oil additive MoSe of the present embodiment 2 The nanosheets were tested by X-ray energy spectroscopy (EDS), and the results were as follows: figure 1 As shown, it can be seen that the atomic ratio of Se / Mo is 1:2 (Se: 63.9%, Mo: 36.10%).

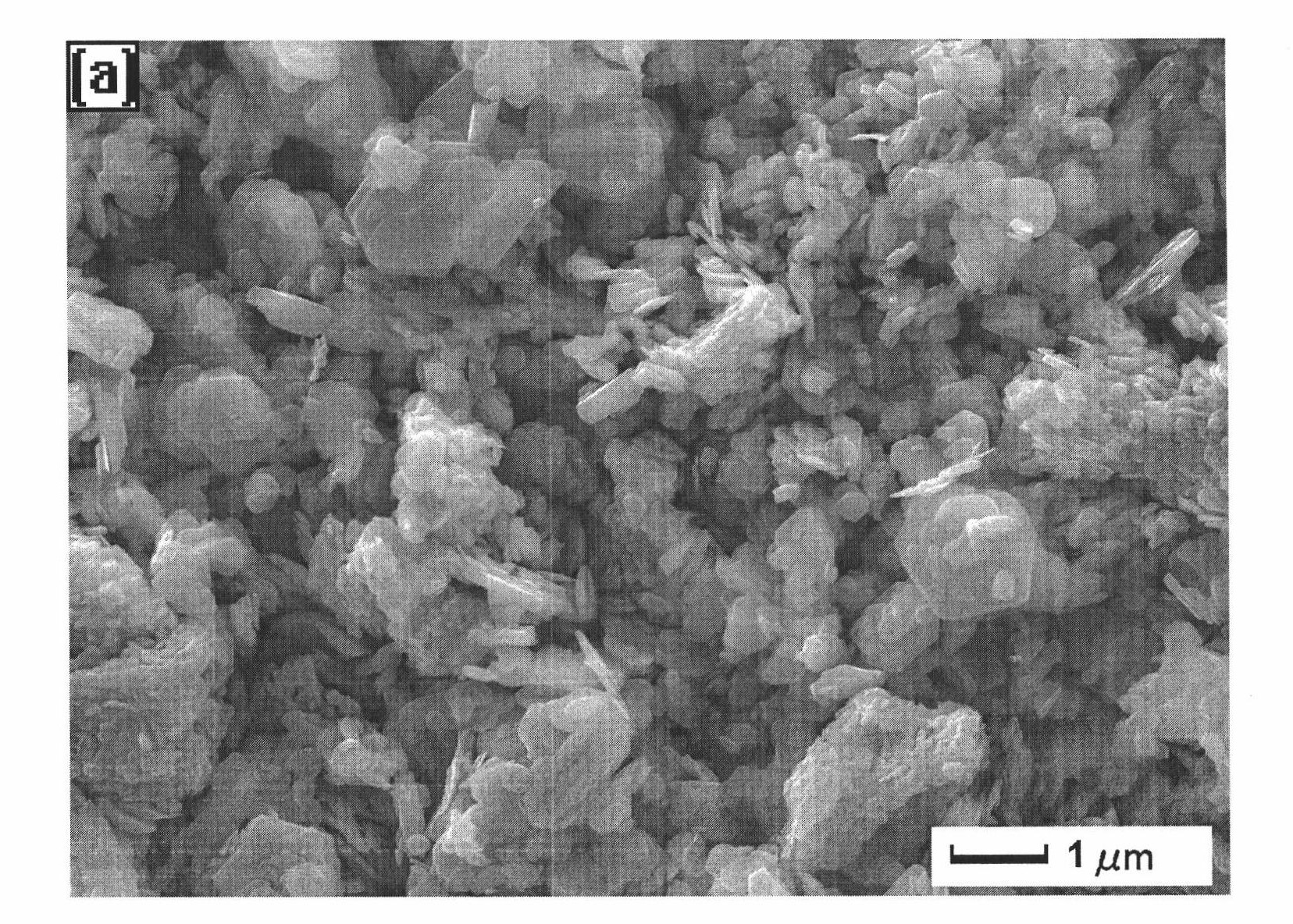

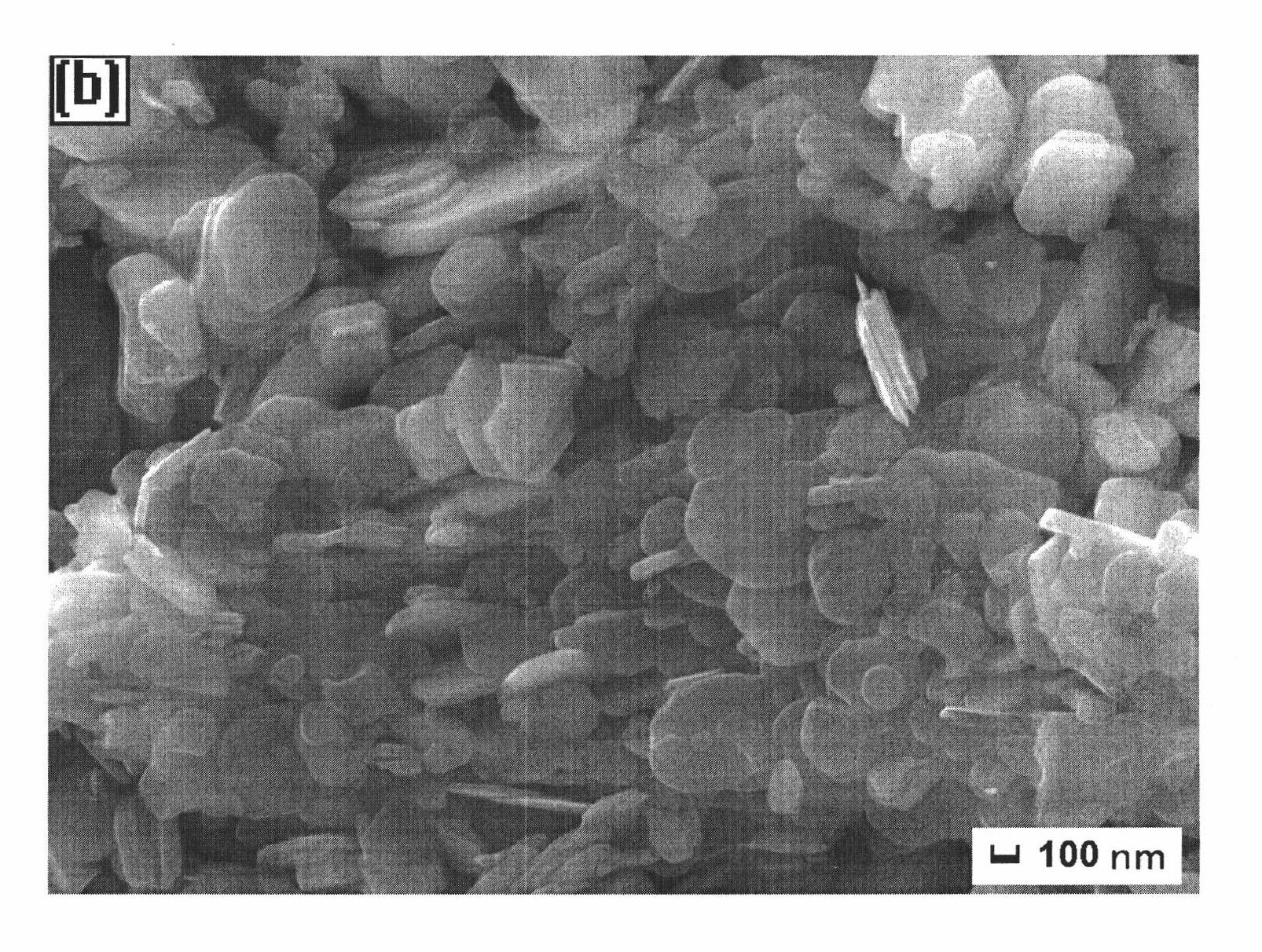

[0017] Observing the solid lubricating oil additive MoSe of the present embodiment...

Embodiment 2

[0019] Embodiment 2: Test solid lubricating oil additive MoSe 2 Tribological properties of nanosheets

[0020] The MoSe of Example 1 2 The nanosheets were added to the base oil 150bn according to the mass concentration of 1%, 5%, and 7%, respectively, and the above three types of MoSe were tested 2 The friction coefficient of the base oil 150bn and 150bn pure oil of nanosheets under different loads (0.5kg, 1kg, 2kg, 3kg, 4kg, 5kg), the load-friction coefficient relationship curve is made for the measurement results, and the results are as follows Figure 4 As shown, it can be seen that the addition of MoSe at different loads 2 The friction coefficient of base oil 150bn of nanosheets is lower than that of 150bn pure oil; under the same load conditions, when MoSe in base oil 150bn 2 When the mass concentration of nanosheets is 5%, the friction coefficient is the lowest. That is, the solid lubricating oil additive MoSe of the present invention 2 Nanosheets can significantly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com