Method for preparing ester by catalytic oxidization of 1,3-propanediol

A technology for catalytic oxidation and propylene glycol, applied in the direction of catalyst activation/preparation, chemical instruments and methods, and preparation of organic compounds, which can solve the problem of low reaction rate and achieve high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

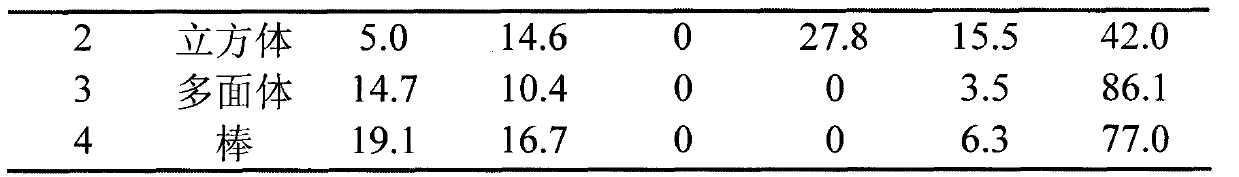

[0021] Embodiment 1 hydrothermal method prepares nanometer ceria of different shapes

[0022] Add 24 grams (or 0.4 grams) of sodium hydroxide and 1.95 grams of cerium nitrate into the reactor, conduct a hydrothermal reaction at 100-180°C for 24 hours, filter and wash until neutral. Dry at 80°C for 12 hours, and bake at 100-1000°C for 4 hours. respectively get CeO 2 Nano-cube, nano-rod and nano-polyhedron carrier, the above-mentioned catalyst carrier is made into 40-60 mesh particles for future use.

Embodiment 2

[0023] Embodiment 2 deposition-precipitation method prepares the catalyst of loading 1%Au (Pd)

[0024] One of urea, sodium carbonate or sodium hydroxide is added to the gold chloride (Pd metal) solution so that the molar ratio is 1:100, and deionized water and oxide carrier are added so that the precious metal:carrier mass ratio is 1 : 100, placed in a water bath at 70-100°C for 2-4h, then the mixture was washed, filtered with suction, and dried. That is, the test catalyst was obtained.

Embodiment 3

[0025] Embodiment 3 prepares Au colloid

[0026] 100μg / mlHAuCl 4 The aqueous solution was added dropwise with 2wt% PVA (M=10000) aqueous solution (PVA / Au(wt / wt)=0.62) under stirring, then stirred for 10min, and then added dropwise with 0.1M freshly prepared NaBH 4 Solution (NaBH 4 / Au (mol / mol)=4), that is, Au colloid is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com