Method for extracting acetone from acetone-dichloromethane-methanol-water mixed liquor by azeotropy and composite extraction reditification integration and equipment thereof

A technology of extractive distillation and methylene chloride, which is applied in the field of azeotropic and compound extractive distillation integration, can solve the problems of high energy consumption and complicated separation process in the separation process, and achieve high product purity, simple process steps, low material consumption and energy consumption low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

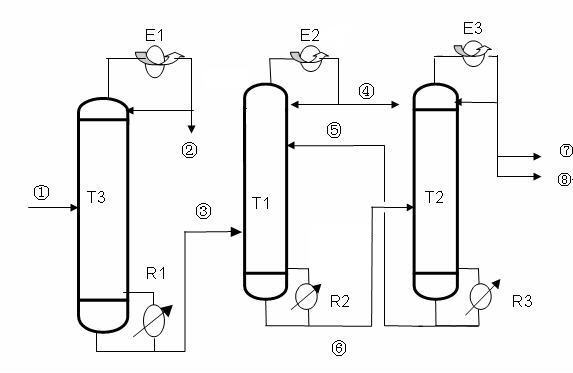

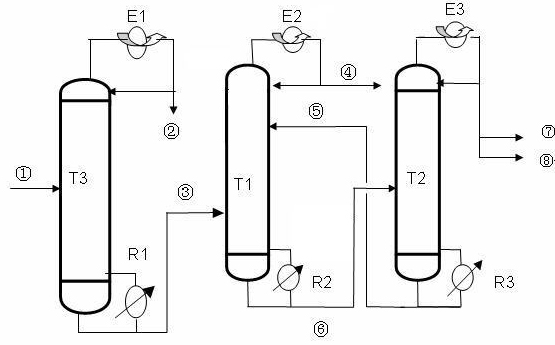

[0028] A kind of process method of azeotropic rectification and compound extractive rectification integrated extraction acetone, refer to figure 1 In the process flow shown, the raw material enters the azeotropic rectification tower T3 and undergoes azeotropic distillation to obtain 50-75% acetone. At the same time, a small amount of dichloromethane is removed, and 50-75% acetone enters the compound extractive rectification tower T1 through After compound extraction and rectification, more than 98.5% of acetone can be obtained at one time, and the yield can reach more than 97%. The mixed extractant is treated by the regeneration tower T2 and then recycled. In the figure, E1, E2 and E3 are the condensers of the towers T3, T1 and T2 respectively, and R1, R2 and R3 are the reboilers of the towers T3, T1 and T2 respectively.

[0029] The raw material ① is a mixture of acetone, dichloromethane, methanol and water, which comes from the by-products in the synthesis reaction of pharma...

Embodiment 2

[0035] Substantially the same as Example 1, but following changes are arranged: the feed rate ratio of sulfolane and ethylene glycol (mixed extractant) is 1: 1.5, mixed solvent and the tower bottom mixed liquor of azeotropic rectification tower T3 3. feed rate ratio 0.8:1.

Embodiment 3

[0037] Substantially the same as Example 1, but with the following changes: the feed ratio of sulfolane and ethylene glycol (mixed extractant) is 1:0.5, and the mixed solvent and azeotropic distillation column T3 tower bottom mixed liquid ③ feed ratio 1.2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com