Low-cost environment-friendly injection-molding high heat-resistant high impact-resistant rigid polyvinyl chloride composite and preparation method thereof

A rigid polyvinyl chloride and injection molding technology, which is applied in the field of high heat-resistant and high-impact rigid polyvinyl chloride compounds and their preparation, can solve the problem that the processability and mechanical properties of the system decrease, the heat-resistant modifier increases the cost, Polyvinyl chloride has poor heat resistance and other problems, and achieves the effect of improving processing fluidity, enhancing dispersion and good heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

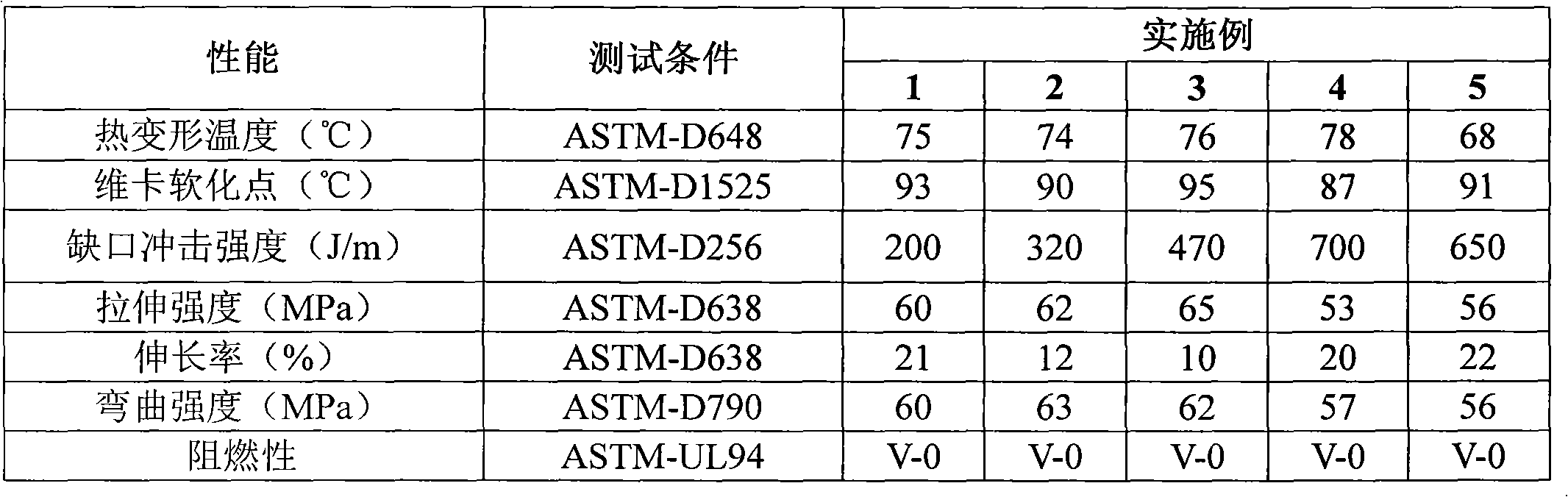

Examples

Embodiment 1

[0020] Add 30 parts by weight of nano-calcium carbonate treated with a coupling agent and 100 parts by weight of acrylonitrile-butadiene-styrene terpolymer of Chimei 766 into a high-speed mixer and mix, discharge and cool to obtain nano-calcium carbonate / propylene Nitrile-butadiene-styrene terpolymer compound; 100 parts by weight of polyvinyl chloride with a degree of polymerization of 1000, 10 parts by weight of polyvinyl chloride with a degree of polymerization of 2500, 2 parts by weight of lanthanum stearate and methyl Put the lanthanum-tin composite stabilizer with a weight ratio of mercaptan organotin of 6:4 into a high-speed mixer, mix to 60°C, add 3 parts by weight of acrylic resin processing aid, 1 part by weight of monoglyceride stearate, and mix to 80°C, add 0.5 parts by weight of oxidized polyethylene wax, mix to 90°C, add nano-calcium carbonate / acrylonitrile-butadiene-styrene terpolymer compound, mix to 120°C, discharge and cool to obtain polychloride Ethylene nano...

Embodiment 2

[0022] Add 5 parts by weight of nano-silica treated with a coupling agent and 100 parts by weight of acrylonitrile-butadiene-styrene terpolymer of Chimei 757 into a high-speed mixer and mix, discharge and cool to obtain nano-silica / acrylonitrile-butadiene-styrene terpolymer compound; 100 parts by weight of polyvinyl chloride with a degree of polymerization of 1300, 10 parts by weight of polyvinyl chloride with a degree of polymerization of 3000, 2 parts by weight of lanthanum stearate Add the lanthanum-tin composite stabilizer with a methylmercaptan organotin weight ratio of 6:4 into a high-speed mixer, mix to 60°C, add 3 parts by weight of acrylic resin processing aid, 1 part by weight of calcium stearate, Mix to 80°C, add 0.5 parts by weight of paraffin, mix to 100°C, add nano-silica / acrylonitrile-butadiene-styrene terpolymer compound, mix to 120°C, discharge and cool to obtain polyvinyl chloride Nanocomposite: Add the polyvinyl chloride nanocomposite to the conical twin-s...

Embodiment 3

[0024] Add 50 parts by weight of nano-calcium carbonate treated with a coupling agent and 80 parts by weight of methyl methacrylate-butadiene-styrene terpolymer with the brand name TP-802 into a high-speed mixer and mix, and cool the discharge to obtain nano Calcium carbonate / methyl methacrylate-butadiene-styrene terpolymer composite; 100 parts by weight of polyvinyl chloride with a degree of polymerization of 700, 10 parts by weight of polyvinyl chloride with a degree of polymerization of 3000, 2 parts by weight The lanthanum-tin composite stabilizer whose weight ratio of lanthanum stearate and methylmercaptan organotin is 6:4 is added into a high-speed mixer, mixed to 60°C, and 3 parts by weight of acrylic resin processing aid, 3 parts by weight of hard Fatty acid, mix to 80°C, add 0.5 parts by weight of paraffin, mix to 100°C, add nano-calcium carbonate / methyl methacrylate-butadiene-styrene terpolymer compound, mix to 120°C, discharge and cool , to obtain a polyvinyl chlori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com