Equipment and method for preparing low-carbon olefins by cracking reactions

A low-carbon olefin, cracking reaction technology, applied in hydrocarbon cracking to hydrocarbon production, detailed information of chemical/physical/physical-chemical reactors, chemical instruments and methods, etc., can solve the problem of expensive materials, increased number of furnaces, and large fuel consumption and other problems, to achieve the effects of not easy coking, simple structure, and reduced investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

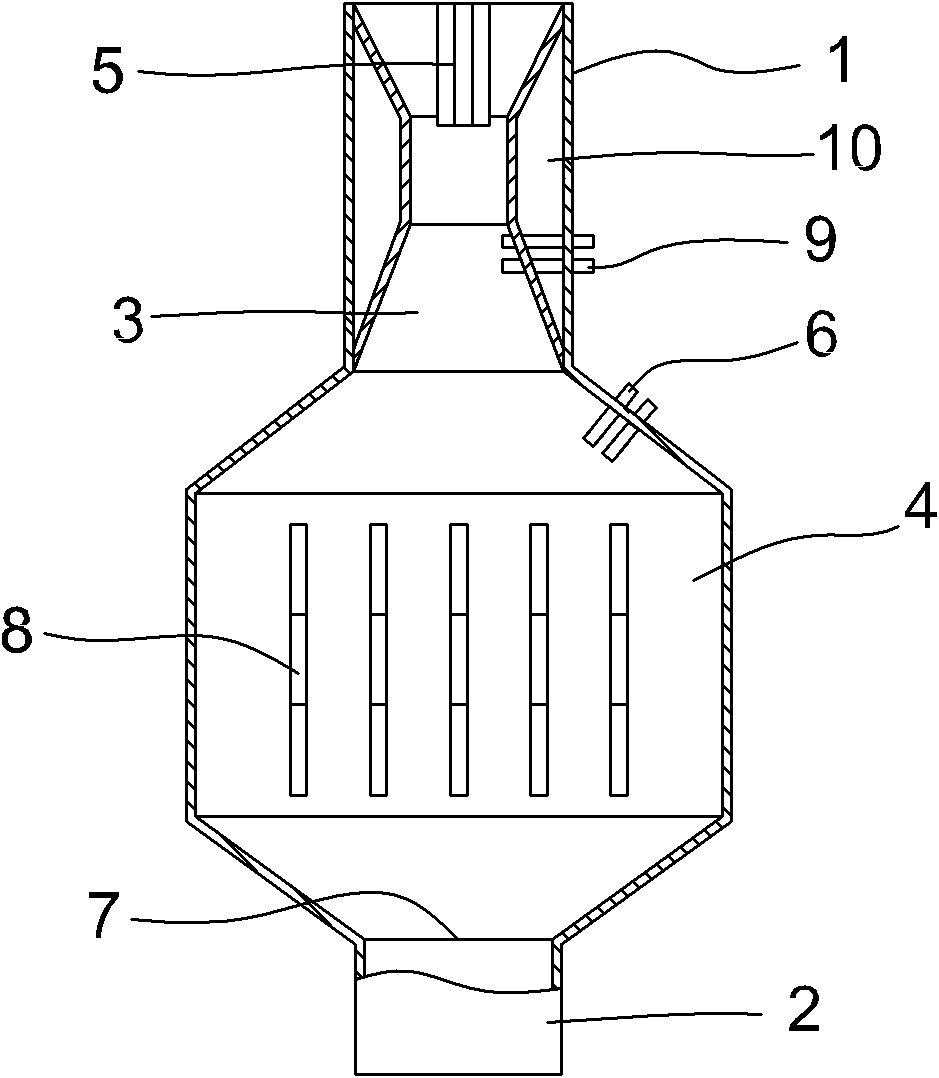

[0056] A reactor for the preparation of low-carbon olefins by thermal cracking reaction, the working state is vertical, and its structure is shown in the attached figure 1 , including the upper inlet port 1 and the lower outlet port 2. Among them, the space inside the inlet end 1, which accounts for 1 / 4 of the entire reactor length, is the combustion zone 3, and the remaining space is the reaction zone 4. The inner wall of the entire combustion zone 3 has a Venturi-type variable-diameter structure. A fuel and oxygen nozzle 5 is provided at the center of the inlet end, a temperature-regulating steam nozzle 9 is provided in the middle of the combustion zone 3, and three raw material nozzles 6 are provided at the diameter expansion of the combustion zone 3 entering the reaction zone 4; End 2 is provided with a product outlet 7 . In addition, there is a flow control system and a raw material distributor at the raw material nozzle 6, a flow control system at the fuel and oxygen n...

Embodiment 2

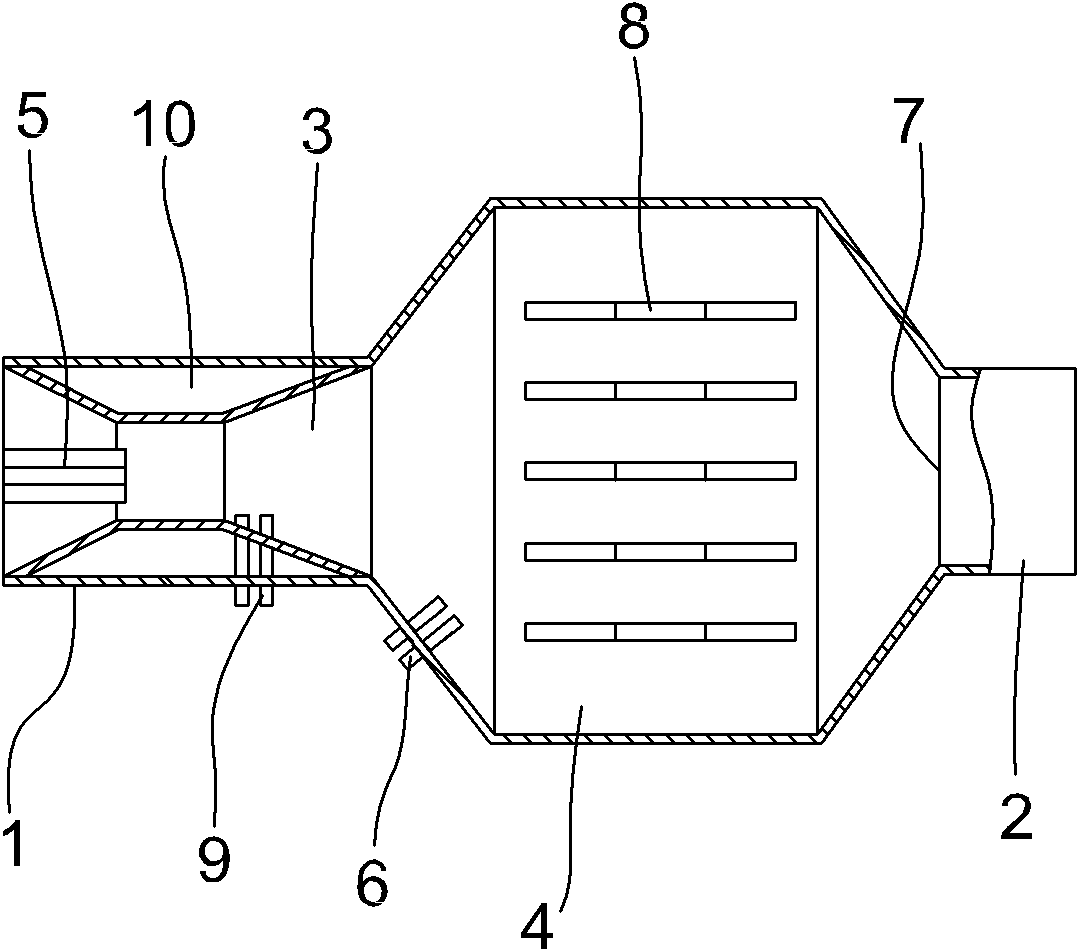

[0058] A reactor for the preparation of low-carbon olefins by thermal cracking reaction, the working state is horizontal, and its structure is shown in the attached figure 2 , with inlet port 1 on the left and outlet port 2 on the right. Among them, inside the inlet end 1, the space accounting for 1 / 4 of the entire reactor length is the combustion zone 3, and the remaining space is the reaction zone 4. The inner wall of the entire combustion zone 3 has a Venturi-type variable diameter structure, and the outer wall of the combustion zone is equipped with a cooling system. Jacket 10. Three fuel and oxygen nozzles 5 are arranged inwardly at the center of the inlet end, a temperature-regulating steam nozzle 9 is arranged in the middle of the combustion zone 3, and three raw material nozzles 6 are arranged at the expanding diameter of the combustion zone 3 entering the reaction zone 4; End 2 is provided with a product outlet 7 . In addition, there is a flow control system and a ...

Embodiment 3

[0060] A reactor for cracking reaction to prepare light olefins, the working state is vertical, its structure is shown in the attached figure 1 , including the inlet port 1 at the bottom and the outlet port 2 at the top. Wherein, inside the inlet port 1, the space accounting for 1 / 4 of the length of the entire reactor is the combustion zone 3, and the rest of the space is the reaction zone 4. The internal diameter of the combustion zone 3 is smaller than the internal diameter of the reaction zone 4. There are 2 fuel and oxygen nozzles 5; an inward raw material nozzle 6 is provided at the expanding diameter of the combustion zone 3 entering the reaction zone 4; a product outlet 7 is provided at the outlet end 2; 5 restrictor plates 8 distributed axially in parallel. In addition, there is a flow control system and a raw material distributor at the raw material nozzle 6, a flow control system at the fuel and oxygen nozzle 5, and a probe type flame combustion detection system in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com