Method for recycling and treating waste circuit board

A waste circuit board, recycling technology, applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of winding, toxicity, impact pyrolysis, etc., and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

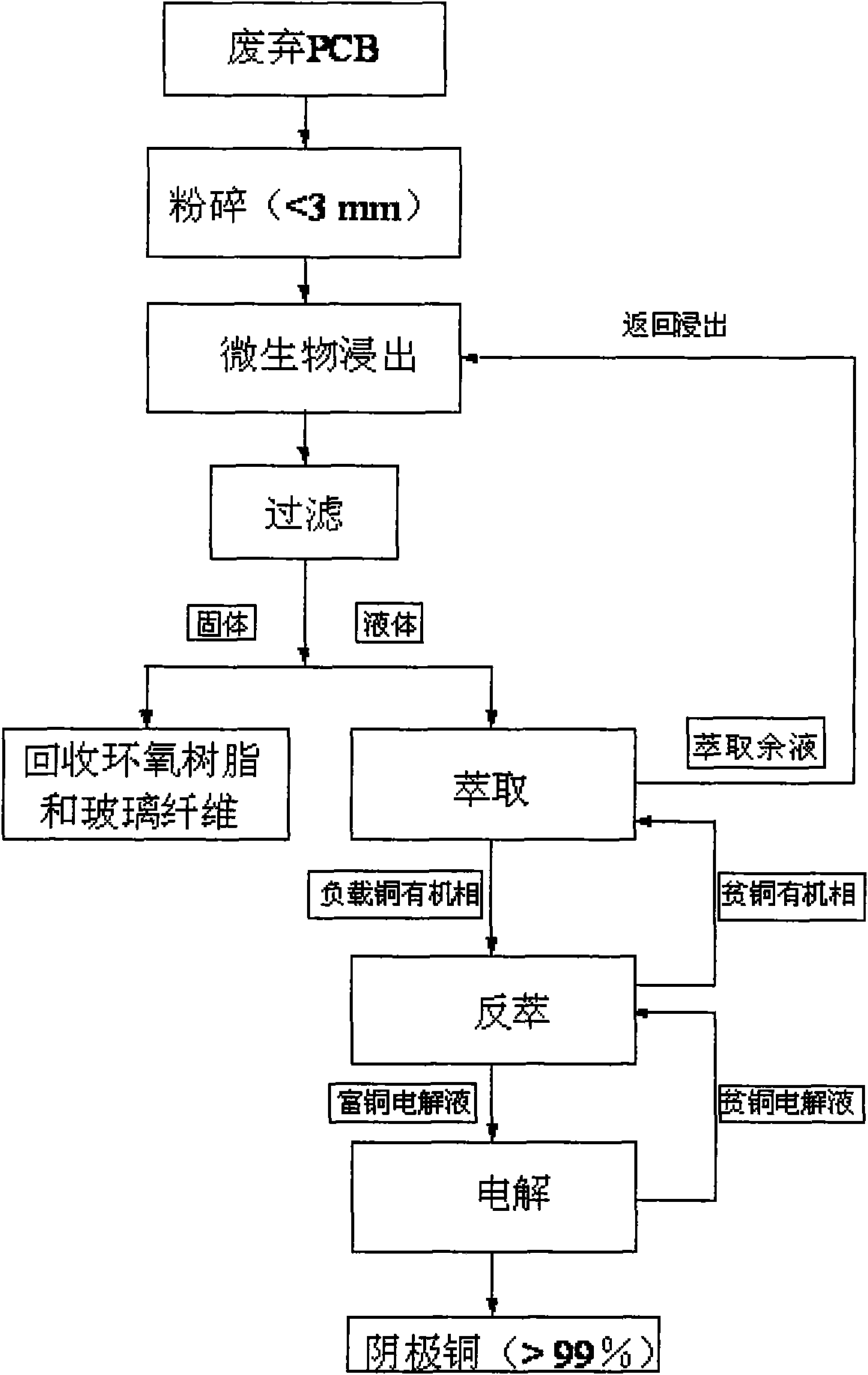

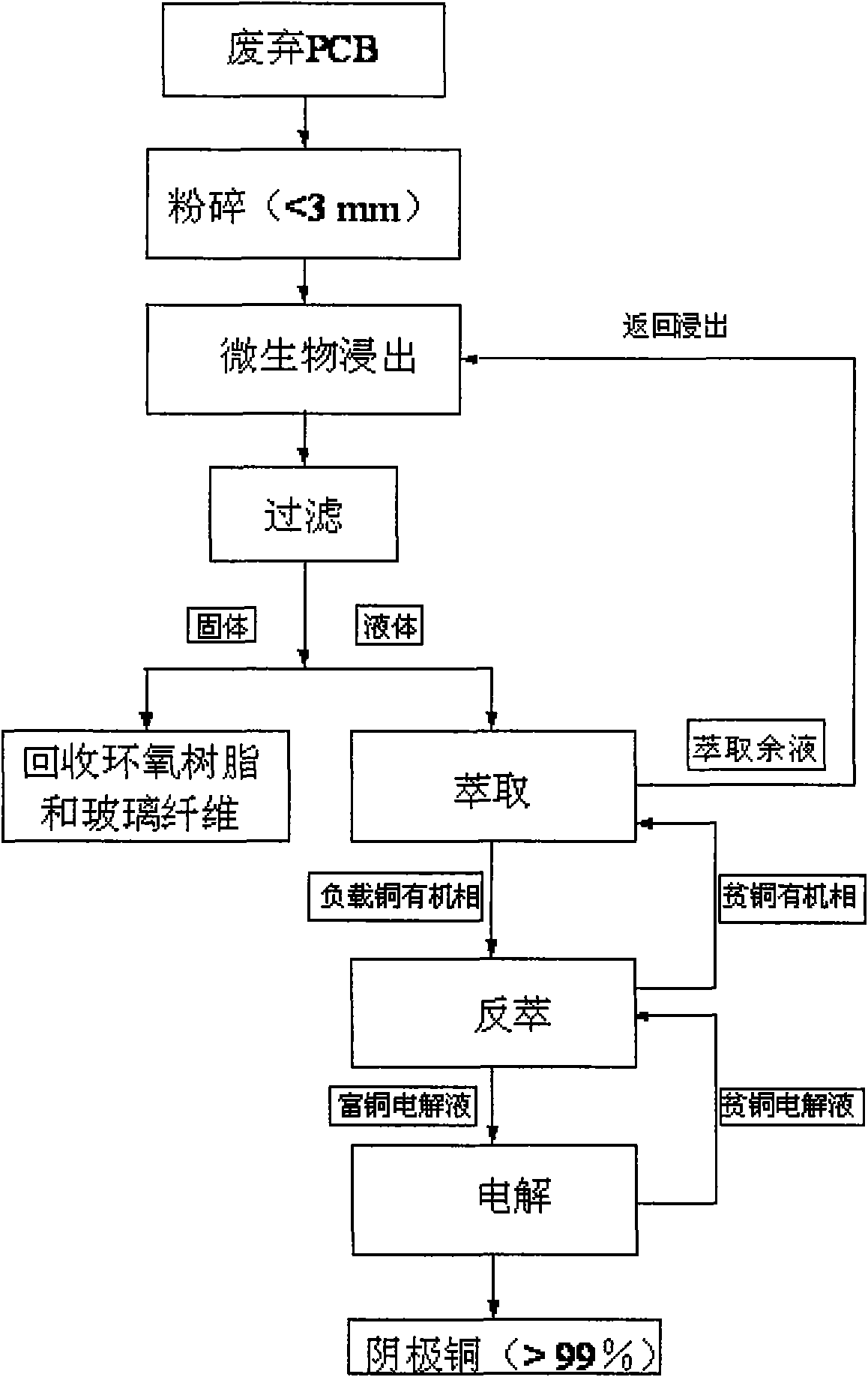

[0013] Referring to Figure 1: A method for recycling waste circuit boards, the steps are: A. Use a pulverizer to crush waste circuit boards into granules, the particle size of which is less than 3mm; B. Put the granules in step A into the reactor for microbial fermentation A kind of leaching reaction, the reaction is made uniform by repeated stirring, the reaction temperature is 25 ℃, the concentration of bacteria is 10mg / l; C, the mixture of step B is separated by a filter, and the solid suspension filtered out is ring The mixture of oxygen resin and glass fiber, the filtrate flows into the mixing and settling tank in the extraction process; D, add the extractant in the mixing and settling tank, after the copper is dissolved in the extracting agent, the filtrate is divided into the upper copper-loaded organic phase and the lower layer The extraction raffinate, divide the organic phase loaded with copper into the stripping tank; E, add inorganic acid in the stripping tank, so t...

Embodiment 2

[0016] In the recovery treatment method of waste circuit board of embodiment 1, described reaction temperature is 28 ℃, and the concentration of bacterial classification is 9mg / l; The microbial bacterial classification in the described step B is Thiobacillus thiooxidans, described The extractant in step D is RE-609; the inorganic acid in step E is sulfuric acid.

[0017] For sufficient recovery, it also includes the step of returning the raffinate in step D to leaching after the oil slick is scraped off. It also includes the step of returning the copper-poor electrolytic solution in the upper layer in step E to extraction treatment. The purity of the obtained elemental copper reaches 99%

Embodiment 3

[0019] In the recovery treatment method of waste circuit board of embodiment 1, described reaction temperature is 30 ℃, and the concentration of bacterial classification is 8mg / l; The microbial bacterial classification in the described step B is Thiobacillus ferrooxidans, Thiobacillus ferrooxidans , the extractant in the step D is N-902 and the inorganic acid in the step E is nitric acid.

[0020] For sufficient recovery, it also includes the step of returning the raffinate in step D to leaching after the oil slick is scraped off. It also includes the step of returning the copper-poor electrolytic solution in the upper layer in step E to extraction treatment. The purity of the obtained copper element reaches 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com