Process and device for recovering complementary energy of silicon smelting furnace

A technology for residual energy recovery and smelting furnaces, which is applied to the improvement of process efficiency, furnaces, energy industries, etc., can solve the problems of only about 50% to 65%, loss, and ineffective use of chemical energy, and achieve thermal energy The effect of sufficient utilization and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

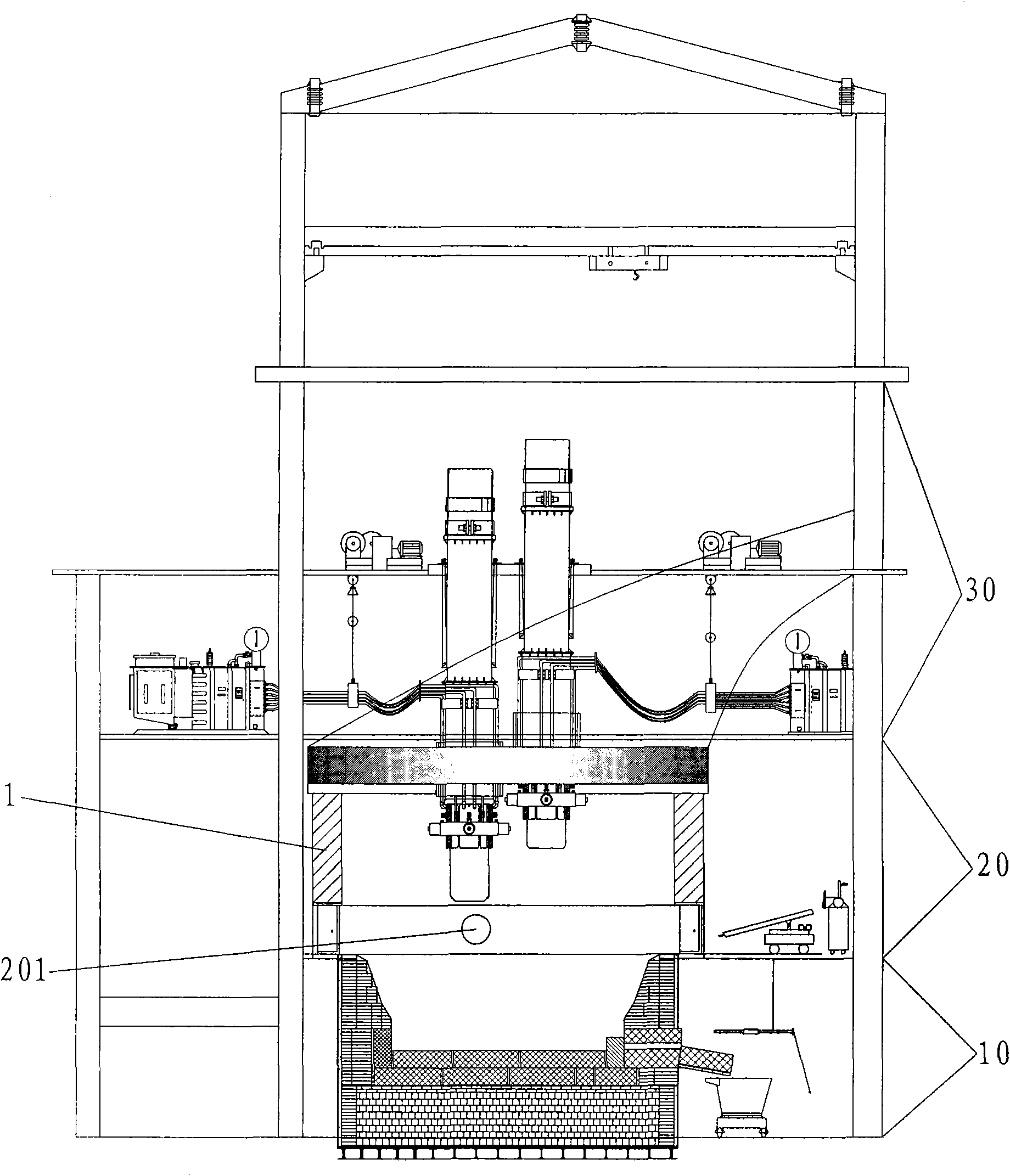

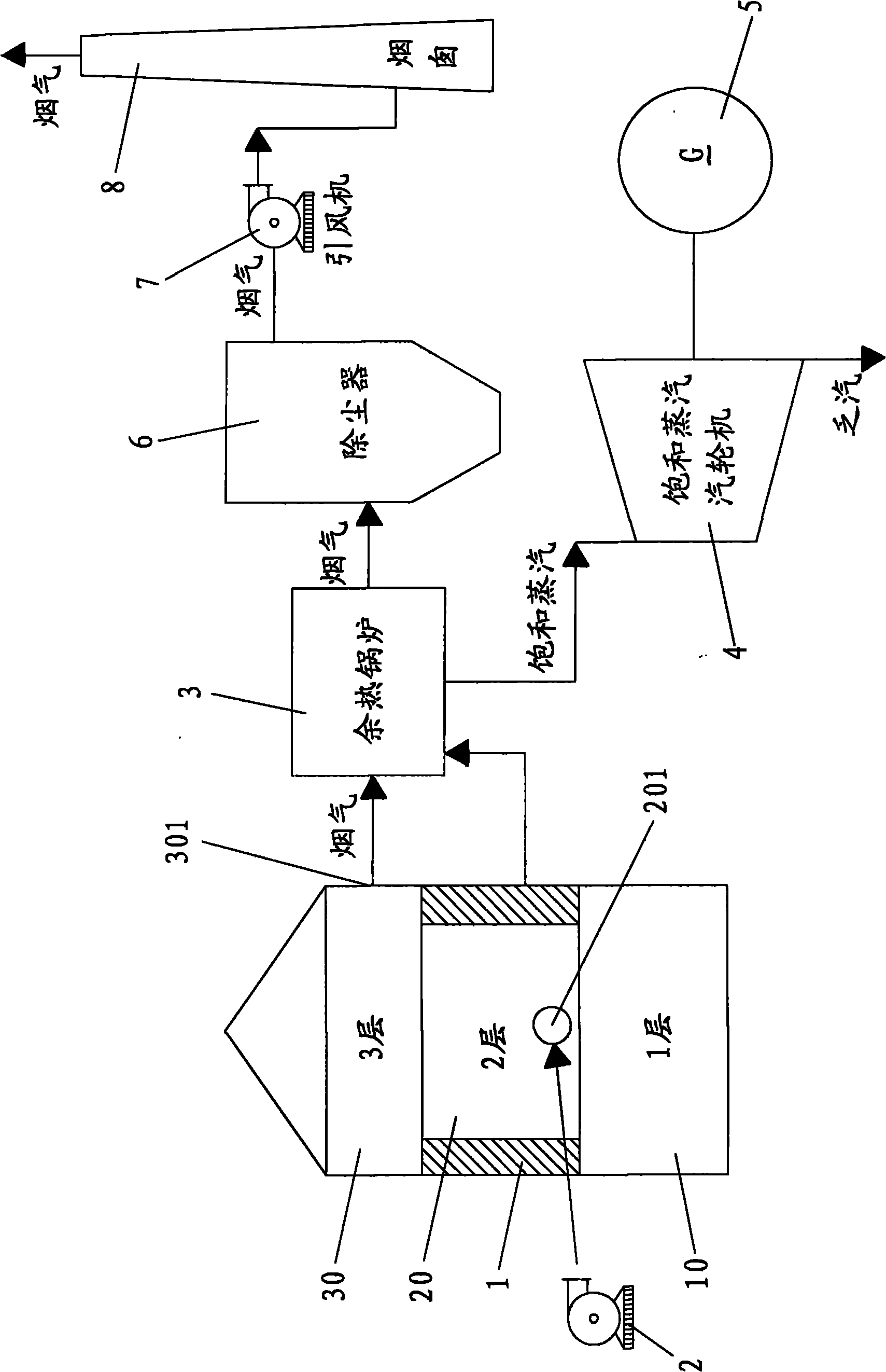

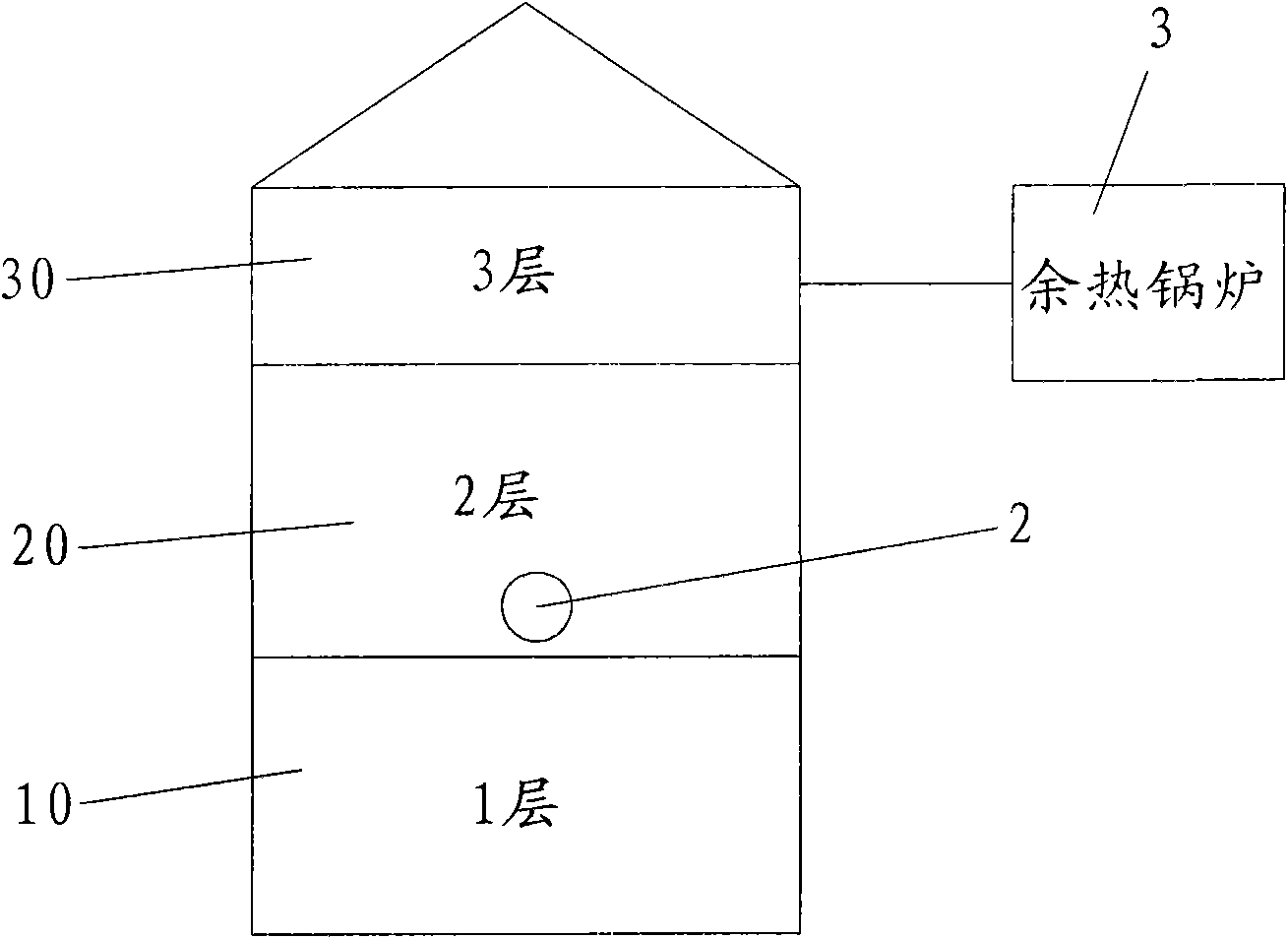

[0025] The present invention is aimed at figure 1 The process and device proposed for the silicon smelting furnace shown. The silicon smelting furnace includes one layer of raw material reaction area 10 , two layers of furnace clearance area 20 , and three layers of furnace cover 30 .

[0026] 1. Process

[0027] The present invention is a silicon smelting furnace residual energy recovery process: (1) installing a radiant heating surface in the clearance area 20 of the furnace on the second floor to lower the temperature of the flue gas in the silicon smelting furnace, protect the electrodes and partially recover the exhaust heat of the smelting furnace; (2) Open the air inlet blast at the lower part of the furnace clearance area 20, reduce the furnace smoke temperature again to protect the electrodes, and burn the CO gas in the exhaust gas to recover chemical energy; (3) at the flue gas outlet of the three-layer furnace cover 30 Install a waste heat boiler to recover the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com