Intelligent organic solid waste subcritical water recycling complete equipment and system

A technology of organic solid waste and complete sets of equipment, applied in the direction of organic fertilizer, solid waste removal, solid fuel, etc., can solve the problems of increased equipment cost, low degree of automation, lengthy process flow, etc., to facilitate maintenance and repair work, improve work Efficiency, the effect of compact overall arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

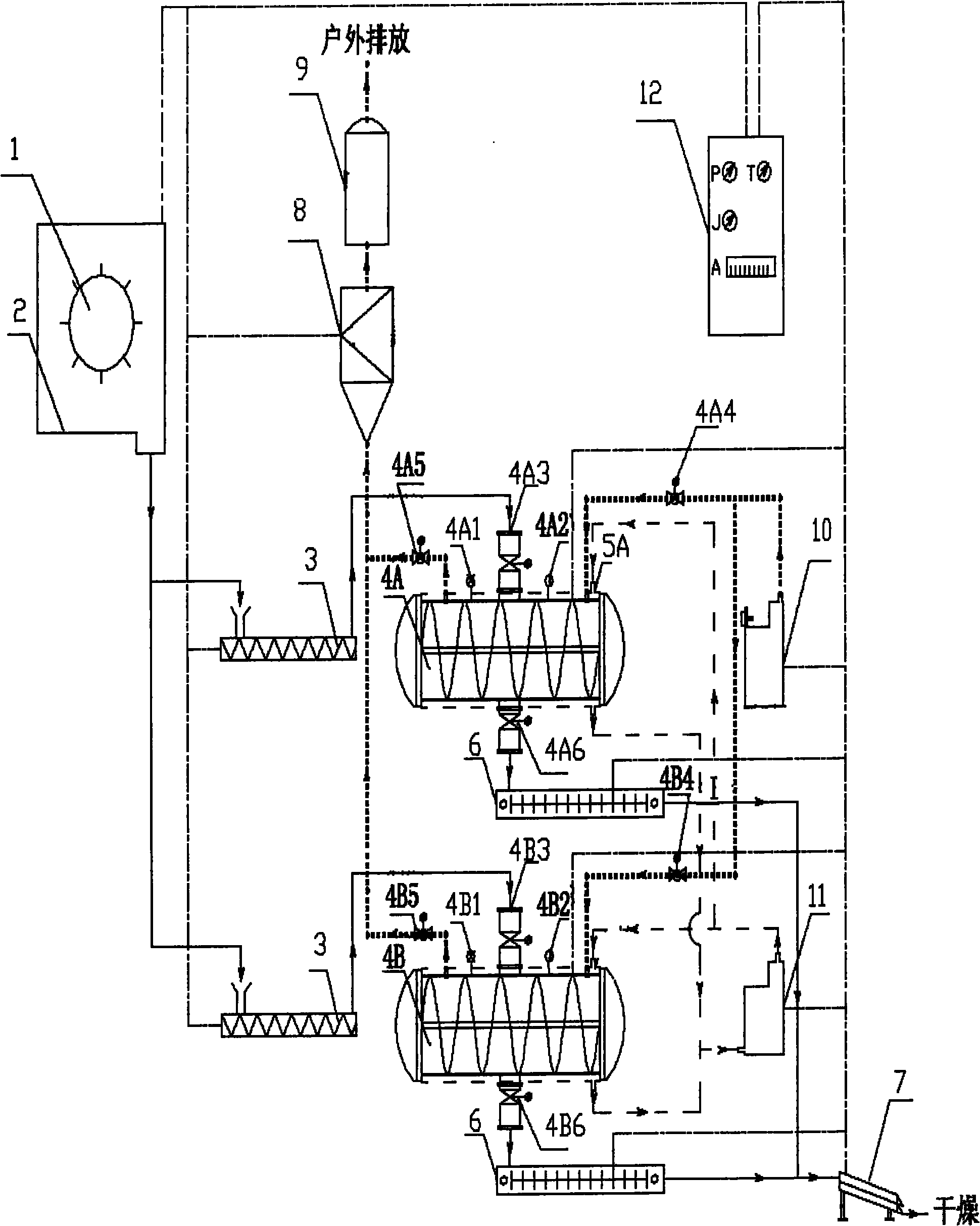

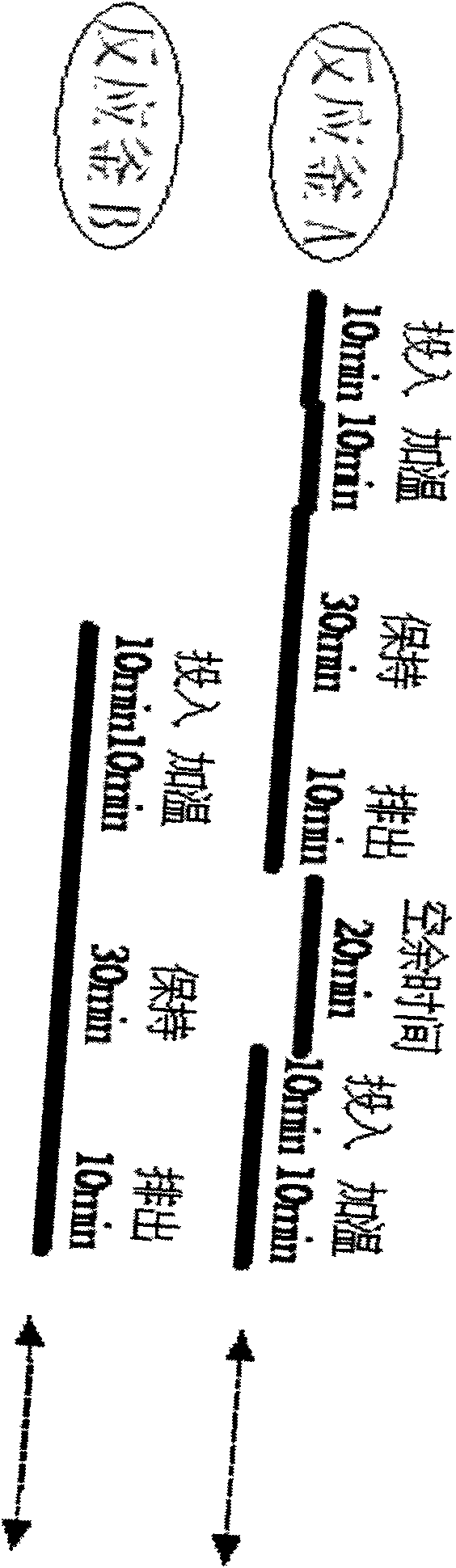

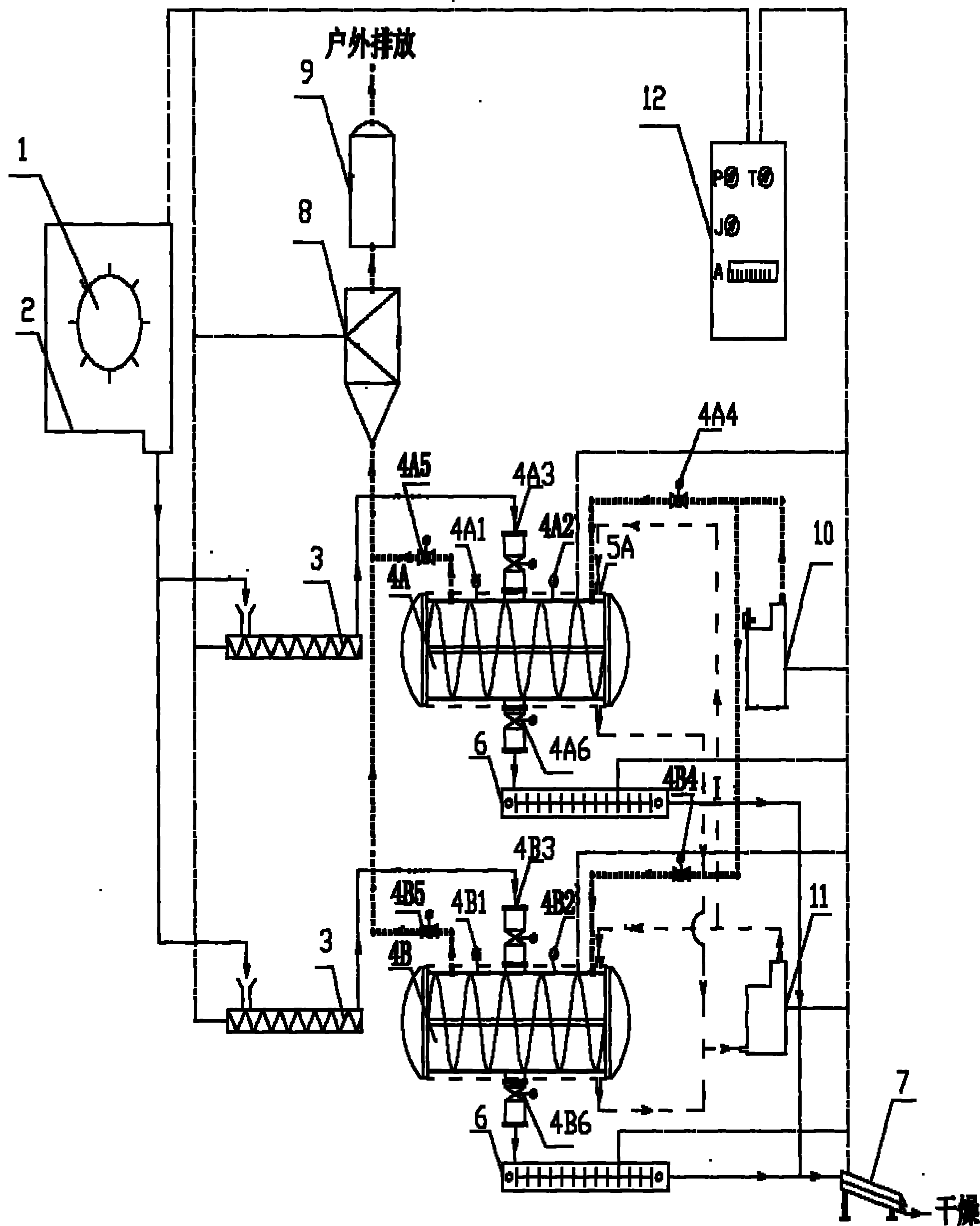

[0040] Using 2 sets of 3m 3 The sequential batch reactor is heated by a steam generator (standard steam volume 2t, 2MPa), and processes 5 tons of kitchen waste and 6 tons of plant fertilizer. According to the test data, the material reaction batch processing time is about 10 minutes for input time, 10 minutes for heating time, 30 minutes for holding time, and 10 minutes for discharge time. Input to intelligent control panel 12 accord with figure 2 The control program required by the process; all materials are crushed by the crusher 1 and stored in the storage box 2 for about 13m 3 ; The intelligent console 12 controls the screw conveyor 3 to convey the material to the main treatment reactor 4A, and fills up after about 10 minutes; the intelligent console 12 controls the steam generator 10 to start heating the main treatment reactor 4A; after about 10 minutes, When the pressure sensor 4A1 and temperature sensor 4A2 reach the specified value (1.8MPa, 200°C), the intelligent c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com