Acid corrosion resistant chloroprene rubber

A chloroprene rubber and acid corrosion resistance technology, applied in the rubber field, can solve the problems of short service life and poor acid corrosion resistance of chloroprene rubber, and achieve the effects of superior high temperature aging resistance, good compatibility and improved resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

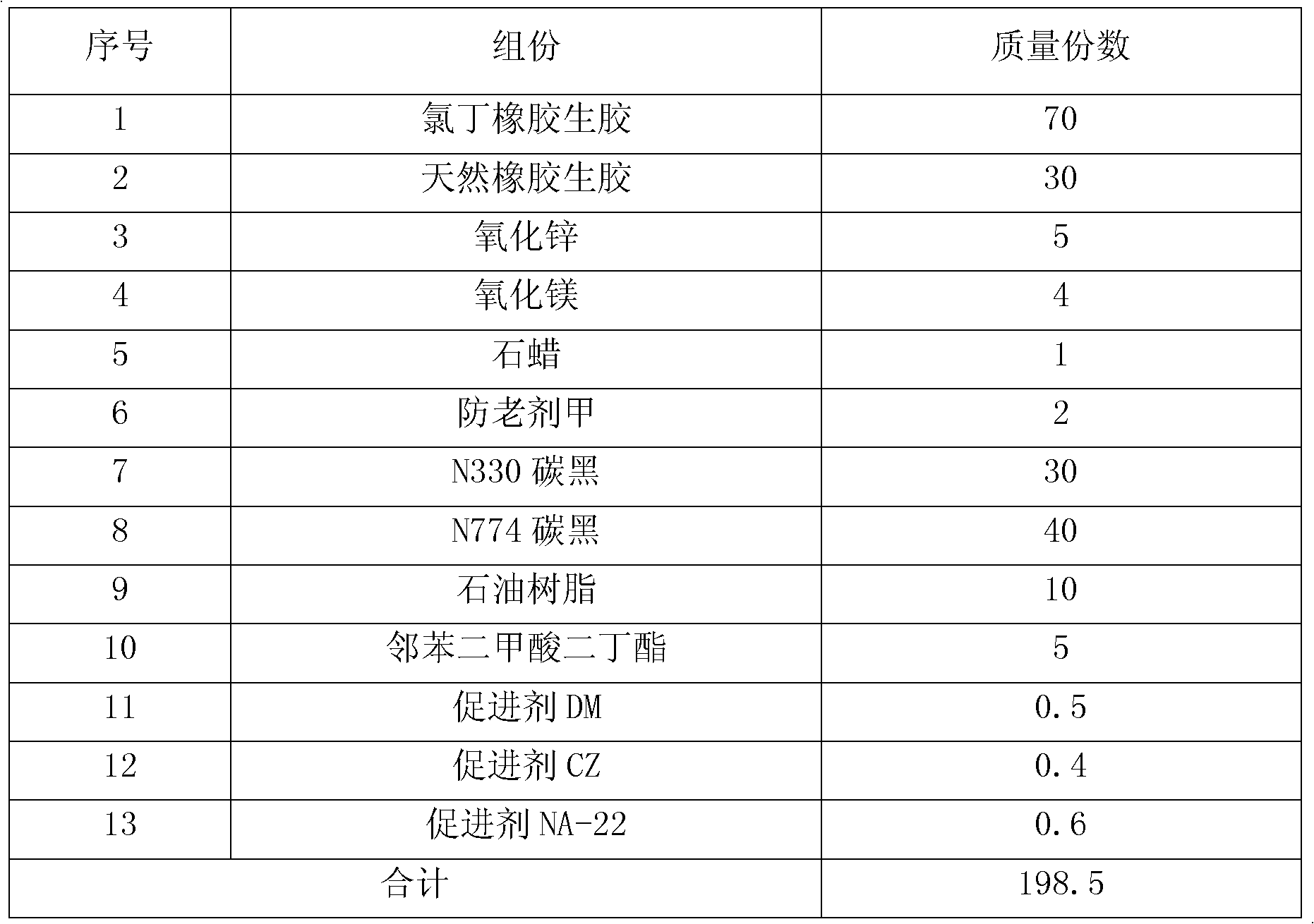

Image

Examples

Embodiment 1

[0012] In parts by mass

[0013] Neoprene raw rubber 100

[0016] Antiaging agent MB 1

[0017] Antiaging agent NBC 0.5

[0018] Paraffin 0.5

[0019] Stearic acid 0.5

[0020] Coumarone 1

[0021] N550 carbon black 20

[0023] Kaolin 20

[0024] Plasticizer SUNDEX790 5

[0025] Vulcanizing agent ETU 0.3

[0026] Accelerator DM 1

[0027] Total: 205.8

[0028] performance:

[0030] Tensile Strength Mpa 14.5

[0031] Elongation at break % 353

[0032] The rubber stoppers produced with this formula did not crack until they were etched more than 1500 times.

Embodiment 2

[0034] In parts by mass

[0035] Neoprene raw rubber 100

[0037] Magnesium oxide 4

[0038] Antiager MB 1.5

[0039] Antiaging agent NBC 0.8

[0040] Paraffin 0.6

[0041] Stearic acid 0.8

[0042] Coumarone 3

[0043] N550 carbon black 30

[0045] Kaolin 30

[0046] Plasticizer SUNDEX790 15

[0047] Vulcanizing agent ETU 0.5

[0048] Accelerator DM 1.5

[0049] Total: 232.7

[0050] performance:

[0052] Tensile Strength Mpa 13.9

[0053] Elongation at break % 348

[0054] The rubber stoppers produced with this formula did not crack until they were etched more than 1500 times.

Embodiment 3

[0056] In parts by mass

[0057] Neoprene raw rubber 100

[0058] Zinc oxide 8

[0059] Magnesium oxide 6

[0060] Antiaging agent MB 1

[0061] Antiaging agent NBC 1

[0062] Paraffin 0.8

[0063] stearic acid 1

[0064] Coumarone 3

[0065] N550 carbon black 40

[0066] Barium sulfate 30

[0067] Kaolin 40

[0068] Plasticizer SUNDEX790 20

[0069] Curing agent ETU 1

[0070] Accelerator DM 2

[0071] Total: 253.8

[0072] performance:

[0074] Tensile Strength Mpa 12.9

[0075] Elongation at break % 334

[0076] The rubber stoppers produced with this formula did not crack until they were etched more than 1500 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com