Preparation method of natural bone repairing material with pre-plasticity

A repair material and natural bone technology, applied in the field of preparation of natural bone repair materials, can solve the problems of no significant improvement in bone reconstruction speed and unfavorable bone tissue reconstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

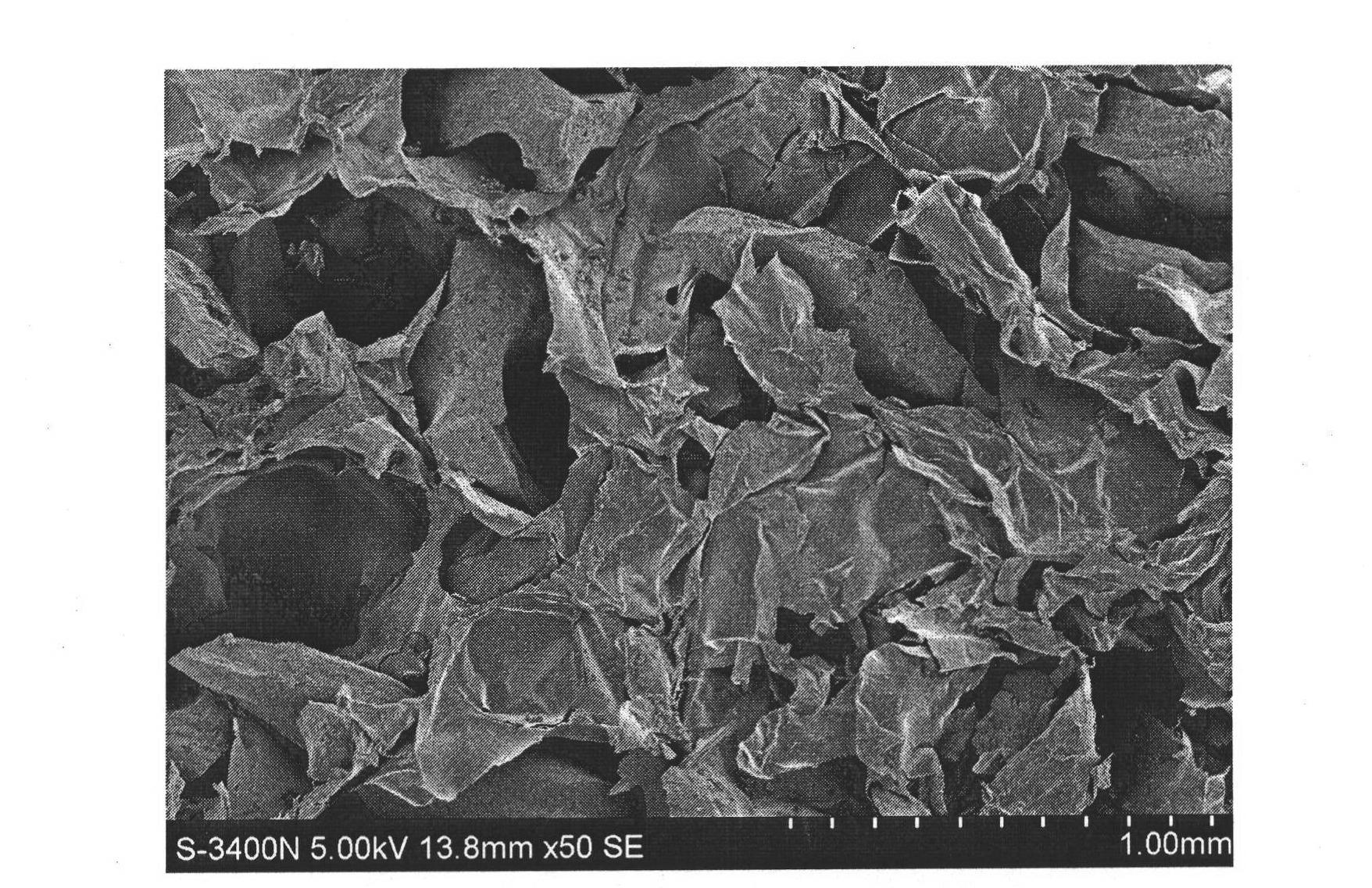

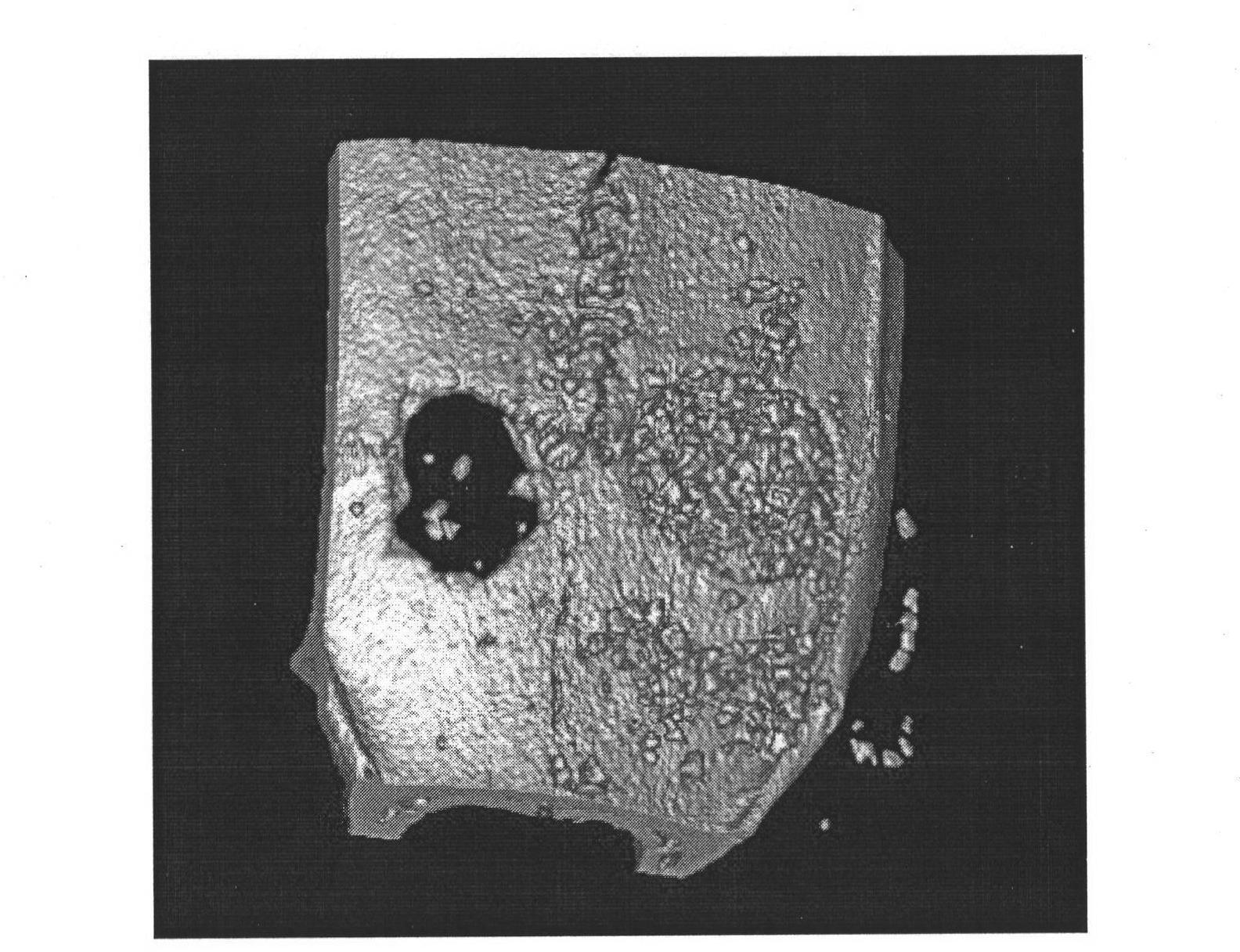

[0024] 1. Removal of organic matter: take bovine femoral epiphyseal cancellous bone, remove the soft tissue on the surface, machine it into broken bone pieces with a particle size of 1-5mm, stir and wash them with pure water for 30 minutes; use ether solution with 2 times the volume of the bone pieces Shake and wash for 20 minutes, then put the bone fragments into 0.5g / L trypsin solution for digestion at room temperature for 70 hours, stir and wash with pure water for 10 minutes, then place them in 1M urea solution for 6 hours, then put them in 1M NaOH solution Medium-ultrasonic cleaning for 2 hours, replace the solution every half an hour, stir and clean with pure water until neutral, and dry in a 37°C oven for 12 hours.

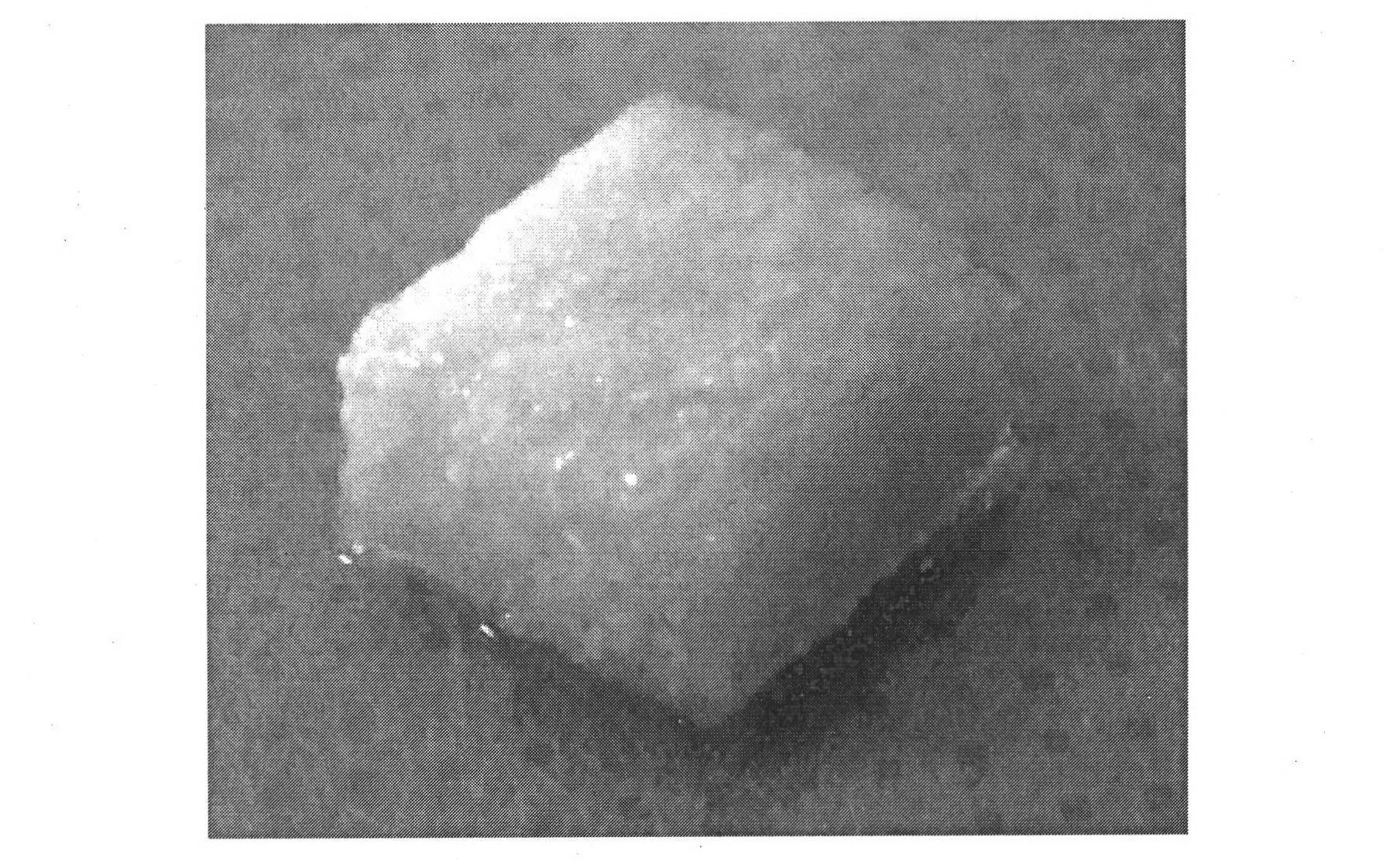

[0025] 2. Calcination and preparation of bone particles: Put the dried bone fragments into a crucible and calcinate in a muffle furnace; heat up to 800°C and then calcine at a constant temperature for 3 hours, then lower the temperature in the furnace to roo...

Embodiment 2

[0030]1. Removal of organic matter: take bovine femoral epiphyseal cancellous bone, remove the surface soft tissue, machine it into broken bone pieces with a particle size of 1-3 mm, wash with pure water for 30 minutes; shake and wash with ether solution twice the volume of the bone pieces After 20 minutes, the bone fragments were digested in 1g / L trypsin solution at room temperature for 46 hours, washed with pure water for 10 minutes, stirred and washed in 1M urea solution for 6 hours, and then ultrasonically cleaned in 1M NaOH solution for 3 hours. hour, change the solution every half hour, stir and wash with pure water until neutral, and dry in a 37°C drying oven for 12 hours.

[0031] 2. Calcination and preparation of bone particles: Put the dried bone fragments into a crucible and calcinate in a muffle furnace; heat up to 600°C and then calcinate at a constant temperature for 5 hours, then lower the temperature in the furnace to room temperature naturally, take out the cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com