Granular spontaneous micro batery sewage treatment agent and preparation method thereof

A sewage treatment agent, a spontaneous technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as secondary pollution, complicated preparation process, and large floor area. Reach the effect of reducing CODcr and chroma, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

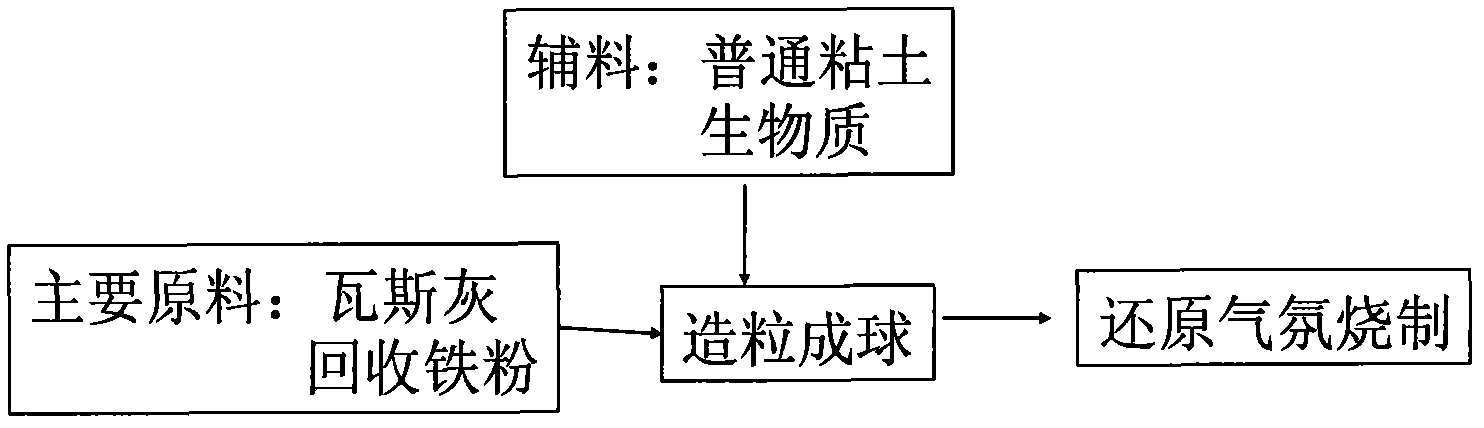

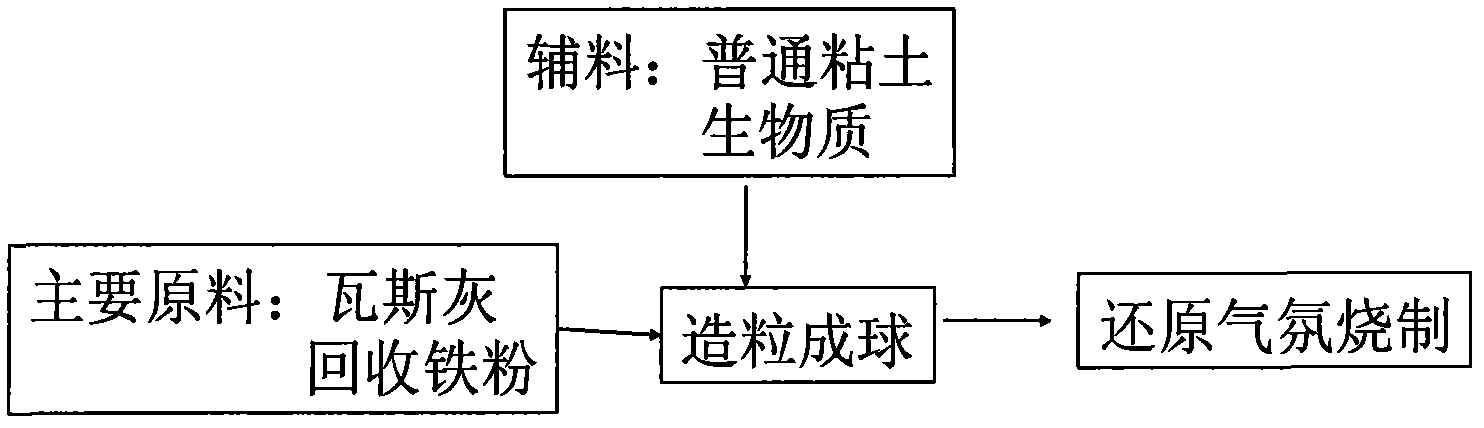

[0013] The preparation process of the granular spontaneous micro-battery sewage treatment agent of the present invention is shown in the accompanying drawings, with gas ash and recycled iron powder as the main raw materials, biomass and ordinary clay as auxiliary materials, and prepared by sintering method, the specific steps are as follows:

[0014] (1) Sieve the dust generated in the blast furnace ironmaking dust removal process to less than 100 mesh (average particle size ≤ 0.154mm) to make gas ash; crush the scrap iron slag in the blast furnace ironmaking process through a ball mill and sieve it to 100 mesh Make recycled iron powder as follows; crush biomass (any crop straw, aquatic plant straw or sawdust) and sieve it to below 100 mesh; crush and sieve clay to below 100 mesh;

[0015] (2) Mix the gas ash, reclaimed iron powder, biomass and common clay prepared in step (1) evenly according to the ratio of 35:38:11:16 in mass ratio, and put the mixed powder in a disc-type ba...

Embodiment 2

[0018] The difference between this example and example 1 is that the mass ratio of gas ash, reclaimed iron powder, biomass and common clay is 45:33:9:13, and the average particle diameter of the raw meal balls made is 5.5 mm. The pellets are sintered at a temperature of 1180° C. for 50 minutes in a high-temperature sintering furnace.

Embodiment 3

[0020] The difference between this example and example 1 is that the mass ratio of gas ash, recycled iron powder, biomass and common clay is 55:28:7:10, and the average particle size of the raw meal balls made is 6mm. The balls are sintered at 1200°C for 45 minutes in a high-temperature sintering furnace.

[0021] The granular spontaneous micro-battery sewage treatment agent fired by the sintering method in the above embodiments can be used for the treatment of heavily polluted textile industry wastewater, the advanced treatment of heavy printing and dyeing wastewater, and the removal of cyanide and Cr from electroplating wastewater. 6+ detoxification treatment, sterilization treatment of hospital wastewater, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com