Polyurethane acrylate adhesive containing ionic groups and preparation method thereof

A polyurethane acrylate, ionic group technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of increased energy consumption, unsuitability, complicated curing process, etc., to achieve high strength and toughness, the effect of increasing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

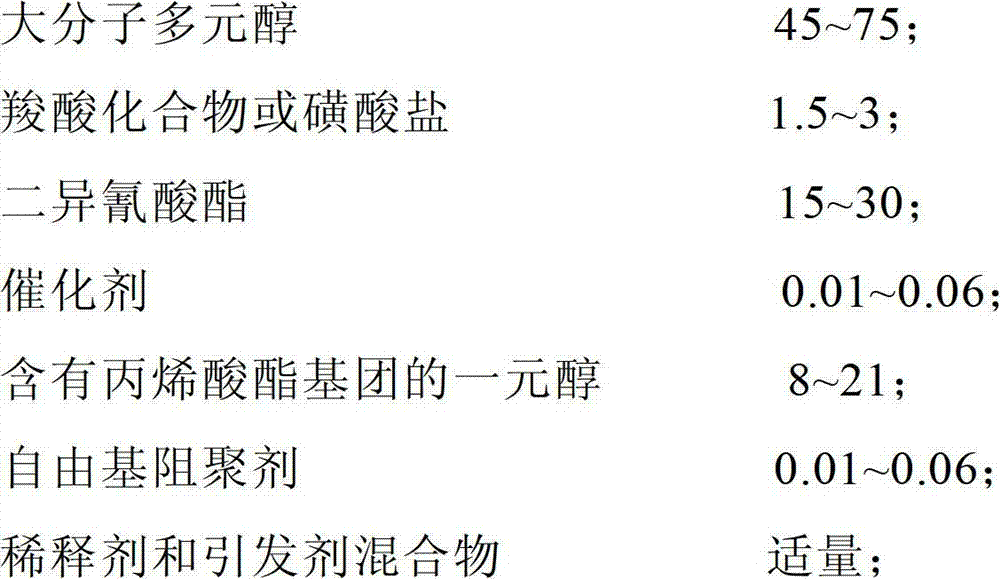

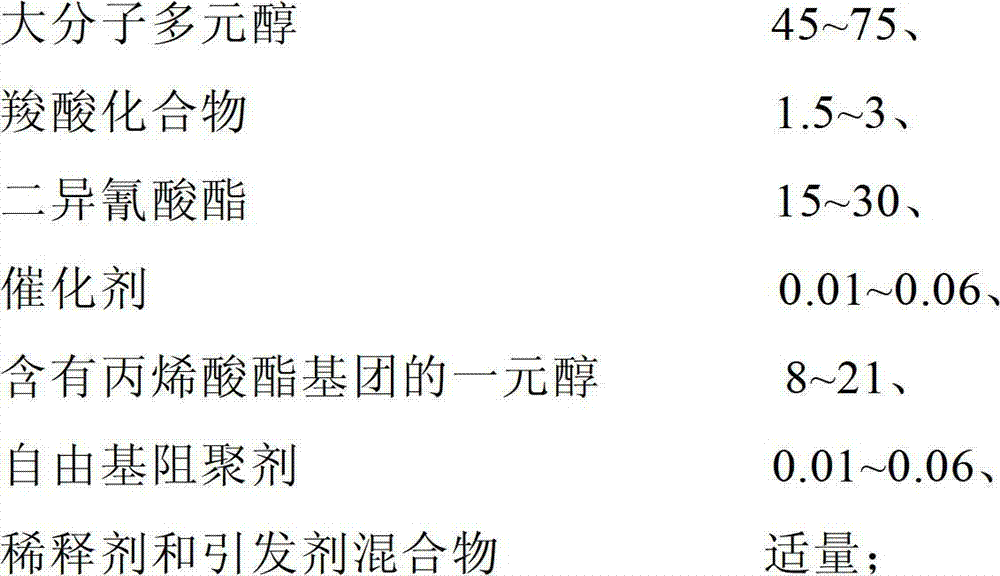

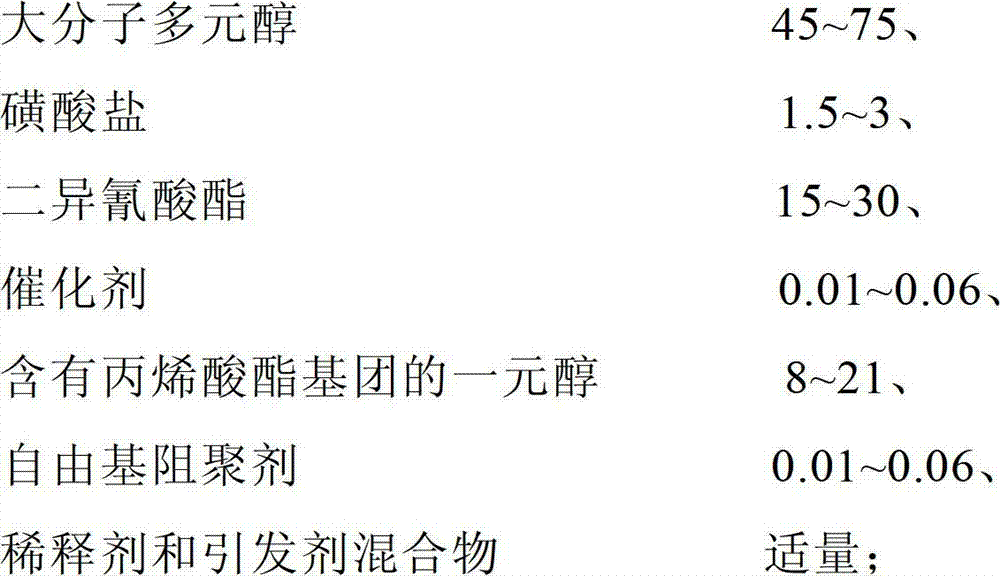

Method used

Image

Examples

Embodiment 1

[0050] 141.3g of polybutylene adipate neopentyl glycol ester with a relative molecular weight of 1500 and a functionality of 2 and 41.9g of polyoxypropylene triol with a relative molecular weight of 1000 and a functionality of 3 are packed into a 500ml three-necked flask , after vacuum dehydration at 110° C. for 1 h, 10.2 g of dimethylol butyric acid was added, and dehydration was continued at 105° C. for 15 min. Then cool down to 60°C, add 100g of isophorone diisocyanate and 0.2g of dibutyltin dilaurate, stir and react at 80°C for 4h, cool down to 55°C, add 47.4g of hydroxyethyl acrylate and 0.1g of terephthalate Phenol, react at 55°C for 3h, so that the terminal NCO group is completely blocked. Bring the reactants below 40°C, add 2.75g of sodium hydroxide for neutralization, and continue stirring for 30 minutes to obtain a polyurethane acrylate polymer with ionic groups.

[0051] Take 26.0g of the above-mentioned polyurethane acrylate polymer with ionic groups, add 11.0g of...

Embodiment 2

[0053]141.3g of polybutylene adipate neopentyl glycol ester with a relative molecular weight of 1500 and a functionality of 2 and 41.9g of polyoxypropylene triol with a relative molecular weight of 1000 and a functionality of 3 are packed into a 500ml three-necked flask , after vacuum dehydration at 110° C. for 1 h, add 13.3 g of sodium dihydroxybutanesulfonate, and continue dehydration at 105° C. for 15 min. Then cool down to 60°C, add 100g of isophorone diisocyanate and 0.2g of dibutyltin dilaurate, stir and react at 80°C for 4h, cool down to 55°C, add 47.4g of hydroxyethyl acrylate and 0.1g of terephthalate Phenol, react at 60°C for 3h, so that the terminal NCO group is completely blocked. That is, a polyurethane acrylate polymer with ionic groups is obtained.

[0054] Take 26.0g of the above-mentioned polyurethane acrylate polymer with ionic groups, add 11.0g of isobornyl acrylate, 3.0g of trimethylolpropane triacrylate, 1.5g of 1173, 2.0g of 184, 0.53g of Benzophenone a...

Embodiment 3

[0056] Put 87.5g of polyoxypropylene polyol with a relative molecular weight of 1300 and a functionality of 7 into a 500ml three-necked flask, dehydrate under vacuum at 110°C for 1 hour, add 15.3g of dimethylol butyric acid, and continue to dehydrate at 105°C Dehydrate for 15min. Then cool down to 60°C, add 150g of isophorone diisocyanate and 0.3g of dibutyltin dilaurate, stir and react at 80°C for 4h, cool down to 55°C, add 71.1g of hydroxyethyl acrylate and 0.2g of terephthalate Phenol, react at 60°C for 3h, so that the terminal NCO group is completely blocked. Bring the reactant below 40°C, add 4.1g of sodium hydroxide for neutralization, and continue stirring for 30 minutes to obtain a polyurethane acrylate polymer with ionic groups.

[0057] Take 26.0g of the above-mentioned polyurethane acrylate polymer with ionic groups, add 11.0g of isobornyl acrylate, 3.0g of trimethylolpropane triacrylate, 1.5g of 1173, 2.0g of 184, 0.53g of di Benzophenone and 0.5g of silane coupl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com