Silicone acrylate coating resin and preparation method thereof

A technology of silicone acrylic resin and silicone resin, which is applied in the direction of coating, graft polymer adhesive, adhesive type, etc., can solve the problems of poor compatibility and comprehensive performance decline of modified acrylic resin system, etc. Achieve the effects of improving comprehensive performance, enhancing paint film performance, aging resistance and excellent paint film performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

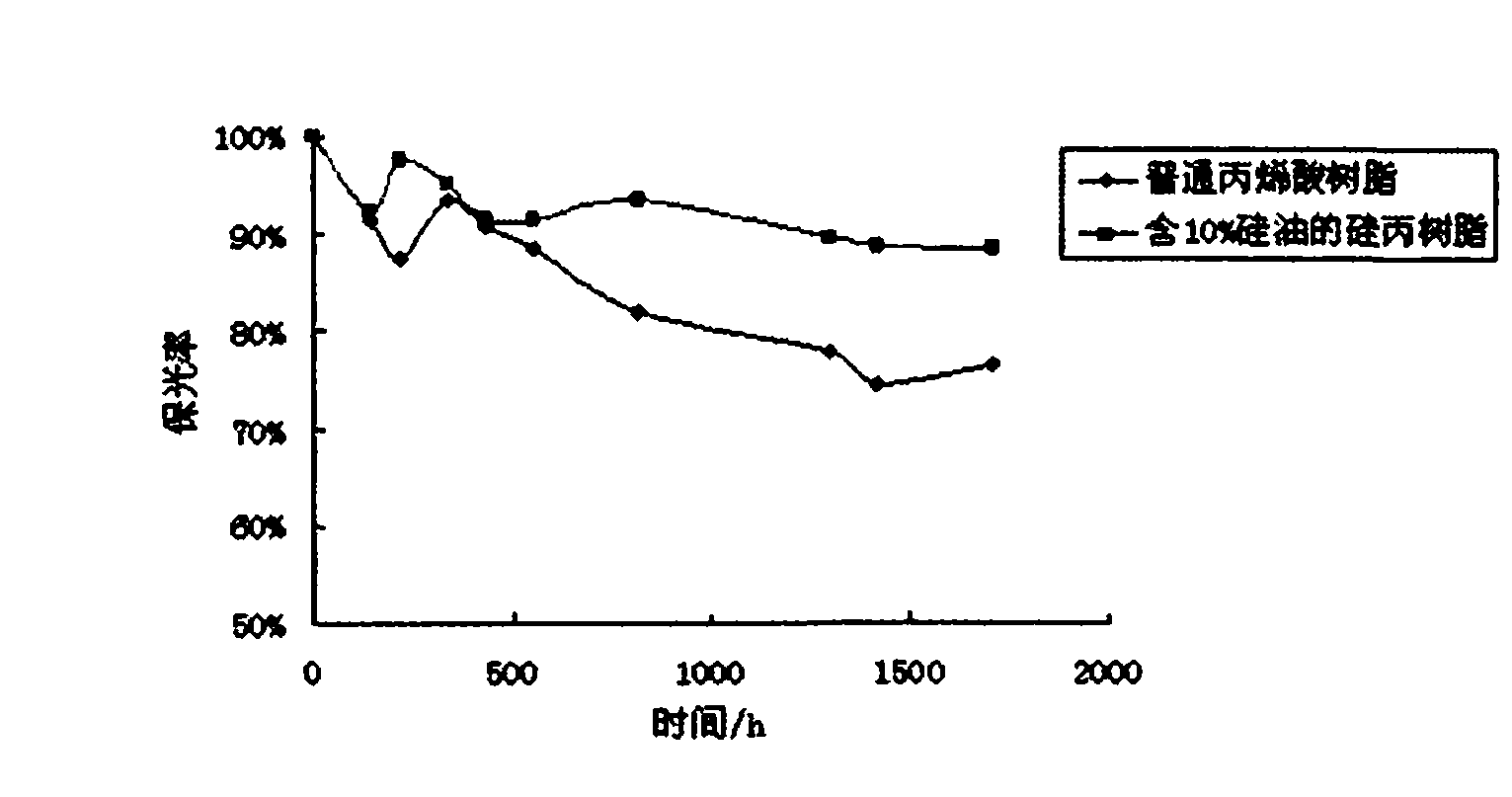

[0056] 1. Preparation of silicone acrylic resin (silicon acrylic resin containing 10% silicone resin)

[0057] In a 500mL four-neck flask, add 80g xylene, 20g isopropanol; weigh 60g methyl methacrylate, 20g butyl acrylate, 10g glycidyl methacrylate, 10g γ-methacryloxypropyl trimethyl Oxysilane is formulated as a mixed monomer, and 0.1g of benzoyl peroxide is added, stirred and dissolved to form a mixed solution; 20g of the above mixed solution is added to the reactor at one time, and kept at 100-110°C for 1 hour under reflux; Then 80g of the above-mentioned mixed solution was added dropwise into the reactor for 2 hours, and after the dropwise addition, it was kept under reflux for 3 hours; then the temperature was lowered, and when the temperature dropped to 80°C, 20g of silicone resin was added, and the heat preservation was continued to obtain Silicone acrylic resin with 10% silicone resin.

[0058] 2. Preparation of coating resin

[0059] Add 15.56 g of curing agent γ-ami...

Embodiment 2

[0061] 1. Preparation of silicone acrylic resin (silicone acrylic resin containing 20% silicone resin)

[0062] In a 500mL four-neck flask, add 60g of xylene and 40g of isopropanol; weigh 60g of n-butyl methacrylate, 20g of ethyl acrylate, 15g of glycidyl methacrylate, and 5g of γ-methacryloxypropyl Trimethoxysilane is formulated as a mixed monomer, and 0.5g of benzoyl peroxide is added, stirred and dissolved to form a mixed solution; 20g of the above mixed solution is added to the reactor at one time, and kept at 100-110°C for 1h under reflux Then 80g of the above-mentioned mixed solution was added dropwise to the reactor for 2 hours, and after the dropwise addition, it was kept in a reflux state for 3 hours; then the temperature was lowered, and when the temperature dropped to 80°C, 40g of silicone resin was added to continue the heat preservation. A silicone acrylic resin containing 20% silicone resin was obtained.

[0063] 1. Preparation of coating resin

[0064] Add...

Embodiment 3

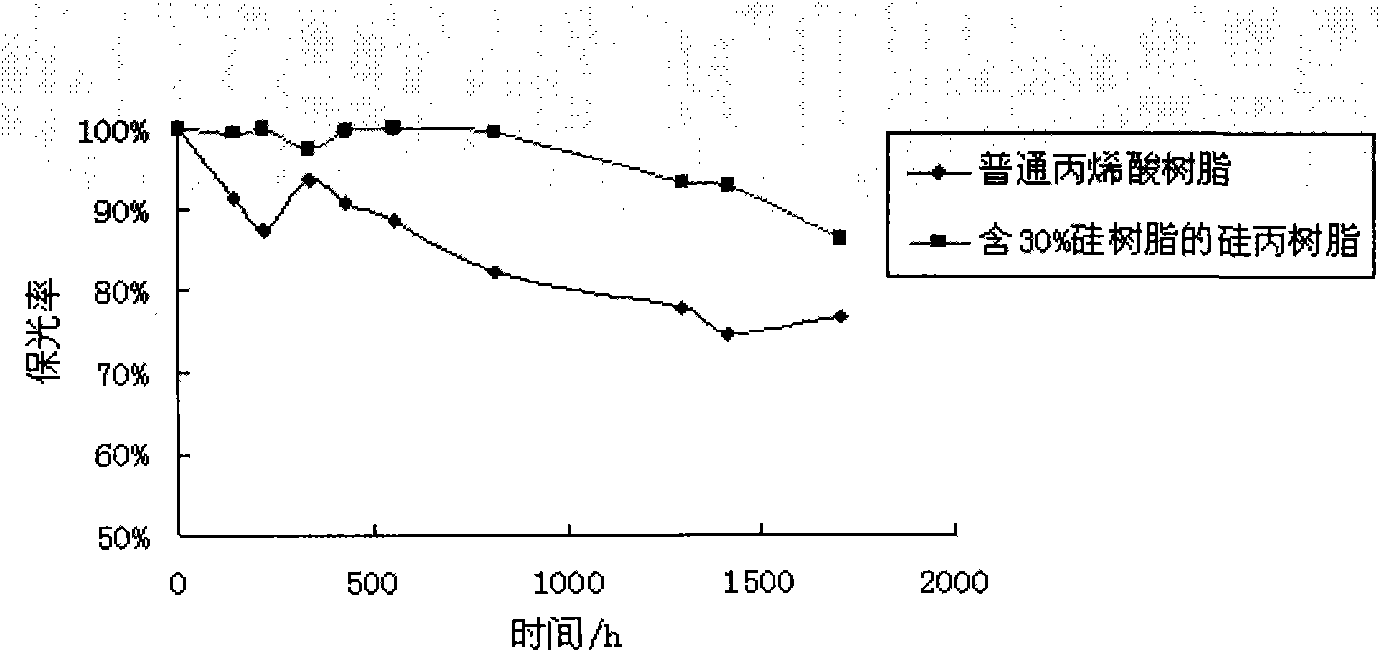

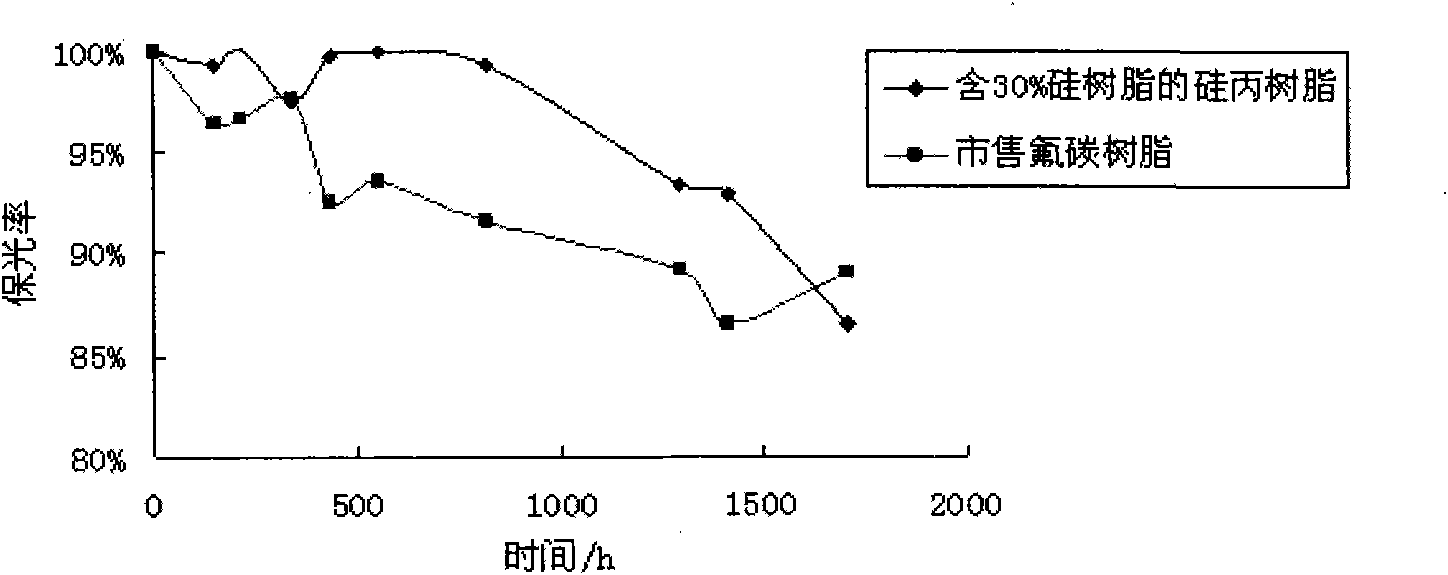

[0066] 1. Preparation of silicone acrylic resin (silicon acrylic resin containing 30% silicone resin)

[0067] In a 500mL four-neck flask, add 50g xylene, 50g isopropanol; weigh 50g methyl methacrylate, 30g butyl acrylate, 10g glycidyl methacrylate, 10g γ-methacryloxypropyl trimethyl Oxysilane is formulated as a mixed monomer, and 0.2g of benzoyl peroxide is added, stirred and dissolved to form a mixed solution; 20g of the above mixed solution is added to the reactor at one time, and kept at 100-110°C for 1h under reflux; Then 80g of the above-mentioned mixed solution was added dropwise to the reactor for 2 hours, and after the dropwise addition, it was kept under reflux for 3 hours; then the temperature was lowered, and when the temperature dropped to 80°C, 60g of silicone resin was added, and the heat preservation was continued to obtain Silicone acrylic resin with 30% silicone resin.

[0068] 2. Preparation of coating resin

[0069] Add 23.3 g of curing agent γ-aminopropy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com