Method for preparing high-dispersion precious metal and alloy nanoparticles thereof

A technology of alloy nanoparticles and precious metals, which is applied in the field of preparation of precious metal alloy nanoparticles, can solve the problems of difficult centrifugation, difficult control of components, and small applicability range, and achieves the advantages of convenient process, low cost, and small particle size distribution range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

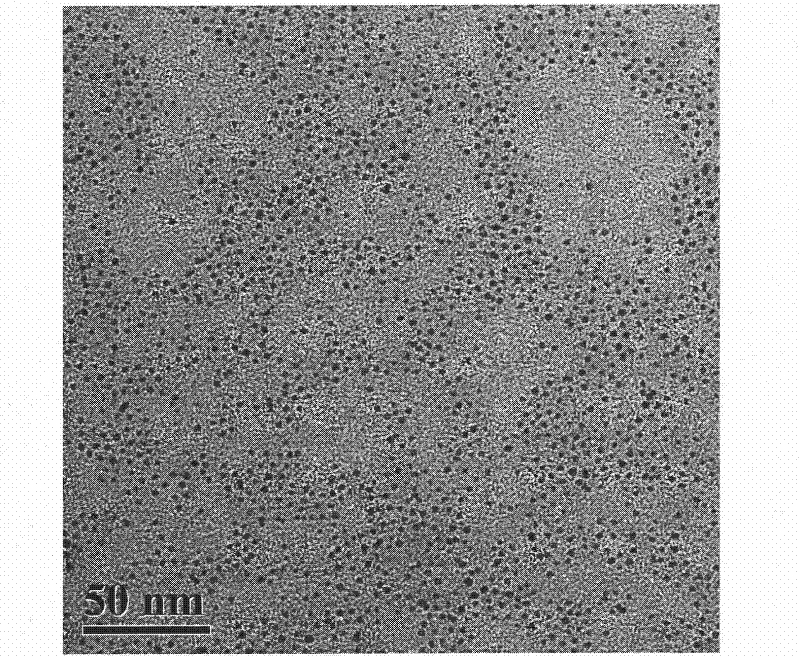

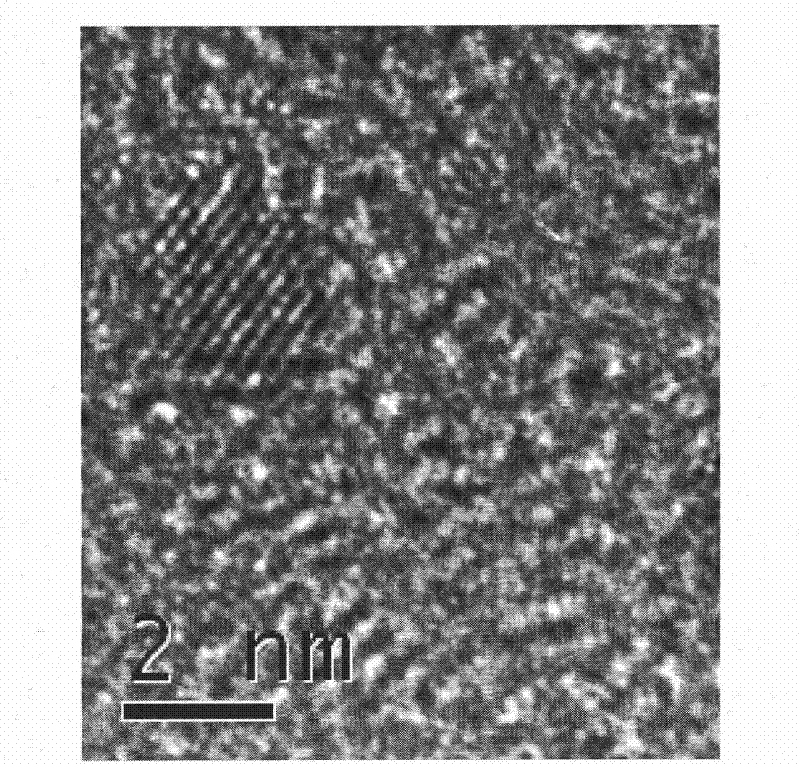

[0031] Take 50 mL of ethylene glycol and add it into a three-necked flask, then add 0.5 mL of oleic acid and oleylamine, and stir and mix evenly at room temperature under an inert atmosphere such as argon. Weigh 0.5mmol of copper acetate and dissolve in 5mL of ultrapure water, weigh 0.5mmol of palladium acetate and dissolve in 5mL of acetone solution, add the two solutions into the mixed solution of ethylene glycol, and then heat up to 120 ℃, keep the temperature for 30 minutes, then continue to heat up to 200 ℃, keep the temperature here for 90 minutes. After the reaction was completed, it was naturally cooled to room temperature, then 50 mL of n-hexane was added, and the mixture was transferred to a separatory funnel for static separation. Take the upper layer solution and remove n-hexane in a rotary evaporator to obtain a viscous nanoparticle solution. Then add ethanol and a small amount of normal hexane to wash, centrifugal drying obtains average particle diameter at 1.9 ...

Embodiment 2

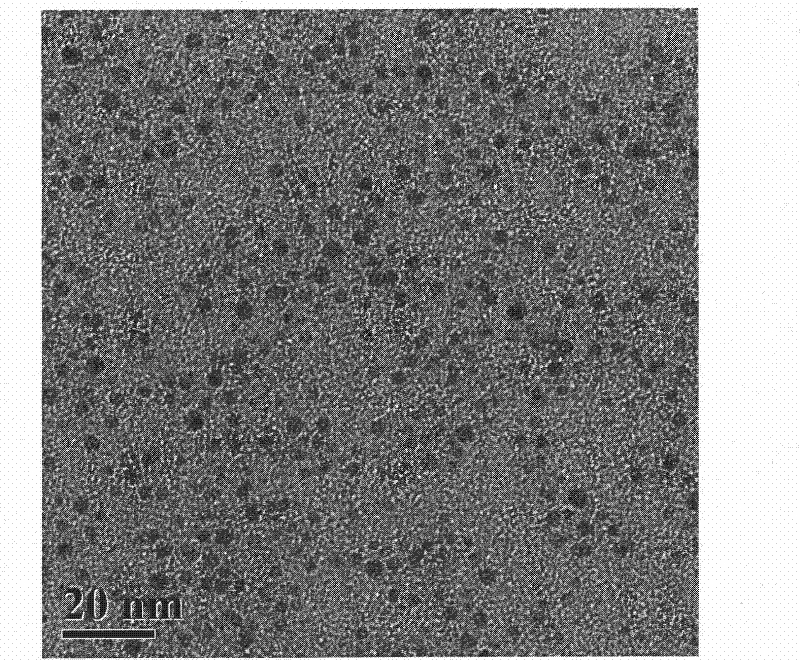

[0033]Take 50 mL of ethylene glycol and add it into a three-necked flask, then add 1 mL of oleic acid and oleylamine, and stir and mix evenly at room temperature under an inert atmosphere such as argon. Weigh 0.5mmol of copper acetate and dissolve in 5mL of ultrapure water, weigh 0.5mmol of palladium acetate and dissolve in 5mL of acetone solution, add the two solutions into the mixed solution of ethylene glycol, and then heat up to 120 ℃, keep the temperature for 30 minutes, then continue to heat up to 200 ℃, keep the temperature here for 90 minutes. After the reaction was completed, it was naturally cooled to room temperature, then 50 mL of n-hexane was added, and the mixture was transferred to a separatory funnel for static separation. Take the upper layer solution and remove n-hexane in a rotary evaporator to obtain a viscous nanoparticle solution. Then add ethanol and a small amount of normal hexane to wash, centrifugal drying obtains average particle diameter at 3 nanom...

Embodiment 3

[0035] Take 50 mL of ethylene glycol and add it into a three-necked flask, then add 1 mL of oleic acid and oleylamine, and stir and mix evenly at room temperature under an inert atmosphere such as argon. Weigh 0.5mmol of copper acetate and dissolve in 5mL of ultrapure water, weigh 0.5mmol of palladium acetate and dissolve in 5mL of acetone solution, add the two solutions into the mixed solution of ethylene glycol, and then heat up to 120 ℃, keep the temperature for 30 minutes, then continue to heat up to 200 ℃, keep the temperature here for 90 minutes. After the reaction was completed, it was naturally cooled to room temperature, then 50 mL of n-hexane was added, and the mixture was transferred to a separatory funnel for static separation. Take the upper layer solution and remove n-hexane in a rotary evaporator to obtain a viscous nanoparticle solution. Then add ethanol and a small amount of normal hexane to wash, centrifugal drying obtains average particle diameter at 4 nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com