Method for dephosphorization in sewage

A sewage and water entry technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of incomplete phosphorus removal, high cost, secondary pollution, etc. The regeneration method is simple and easy to implement, the time is short, and the cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

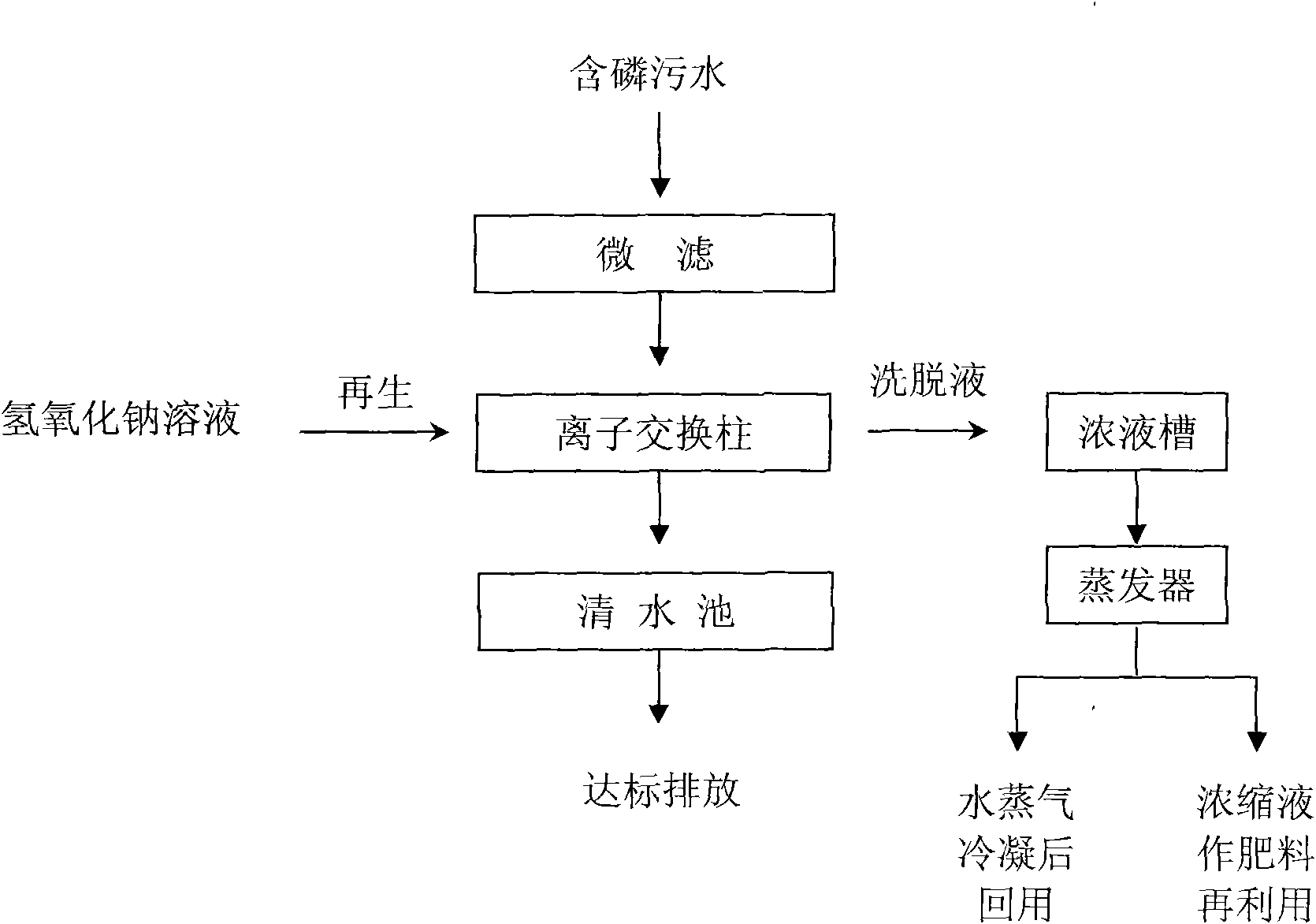

Image

Examples

Embodiment 1

[0016] Phosphorus-containing sewage from an automobile manufacturing plant, the water quality is as follows: phosphorus content 4.5-5.4 mg / L, turbidity 8.6-1 74.9 NTU. Adopt the inventive method to carry out dephosphorization, and the specific implementation mode is:

[0017] (1) Phosphorus-containing sewage is first filtered through a microfiltration membrane. The microfiltration membrane is a polyethylene tubular microfiltration membrane with a membrane pore size of 0.1-1 μm and a porosity of 70-95%. The operation adopts dead-end filtration, and the operating pressure difference is 0.1-0.3 Mpa, the turbidity of the product water after microfiltration treatment is less than 1.0 NTU;

[0018] (2) The water produced by microfiltration enters the ion exchange fixed bed, and the fixed bed is filled with strong alkali acrylic anion exchange resin, the phosphorus in the sewage is absorbed and enriched in the fixed bed, the phosphorus content drops below 0.5mg / L, and the produced wa...

Embodiment 2

[0022] The water quality of the effluent of a city sewage treatment plant after biological treatment is as follows: phosphorus content 1.0-1.5 mg / L, SS=6.8-24.3 mg / L. Adopt the method of the present invention to carry out depth dephosphorization treatment, the specific implementation mode is:

[0023] (1) Phosphorus-containing sewage is first filtered through a microfiltration membrane. The microfiltration membrane is a polyvinylidene fluoride hollow fiber membrane with a pore size of 0.05-0.2 μm and a porosity of 50-70%. Cross-flow filtration is used during operation, and the operating pressure difference 0.01~0.045Mpa, after microfiltration treatment, the produced water SS<1.0 mg / L;

[0024] (2) The water produced by microfiltration enters the ion exchange fixed bed, which is filled with macroporous strong base quaternary ammonium anion exchange resin, the phosphorus in the sewage is absorbed and enriched in the fixed bed, and the phosphorus content drops below 0.4mg / L , th...

Embodiment 3

[0028] The water quality of the effluent of an urban sewage treatment plant after biological treatment is as follows: phosphorus content 0.8-1.2 mg / L, SS=4.2-18.6 mg / L. Adopt the method of the present invention to carry out depth dephosphorization treatment, the specific implementation mode is:

[0029] (1) Phosphorus-containing sewage is first filtered through a microfiltration membrane. The microfiltration membrane is a cellulose acetate membrane with a pore size of 0.2-10 μm and a porosity of 30-45%. Cross-flow filtration is used during operation, and the operating pressure difference is 0.05-0.1Mpa , after microfiltration treatment, the product water SS<1.0 mg / L;

[0030] (2) The water produced by microfiltration enters the ion exchange fixed bed, and the fixed bed is filled with strong alkali styrene anion exchange resin, the phosphorus in the sewage is absorbed and enriched in the fixed bed, and the phosphorus content drops below 0.4mg / L. water enters the clear pool;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com