Anticorrosive paint composition

A composition, anti-corrosion pigment technology, applied in anti-corrosion coatings, polyester coatings, epoxy resin coatings, etc., can solve problems such as unsatisfactory durability, achieve excellent corrosion resistance, improved corrosion resistance, excellent The effect of tackifying properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

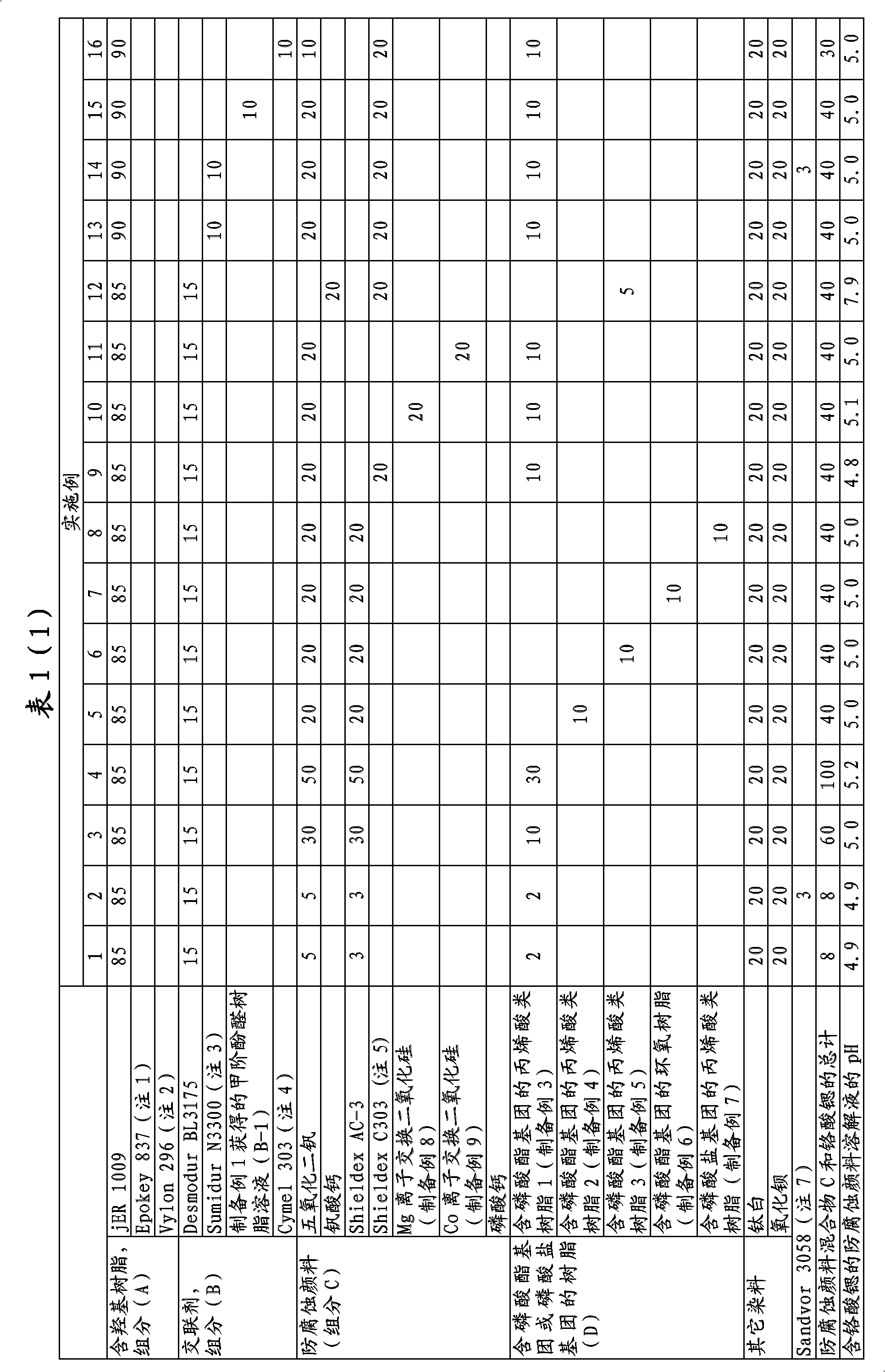

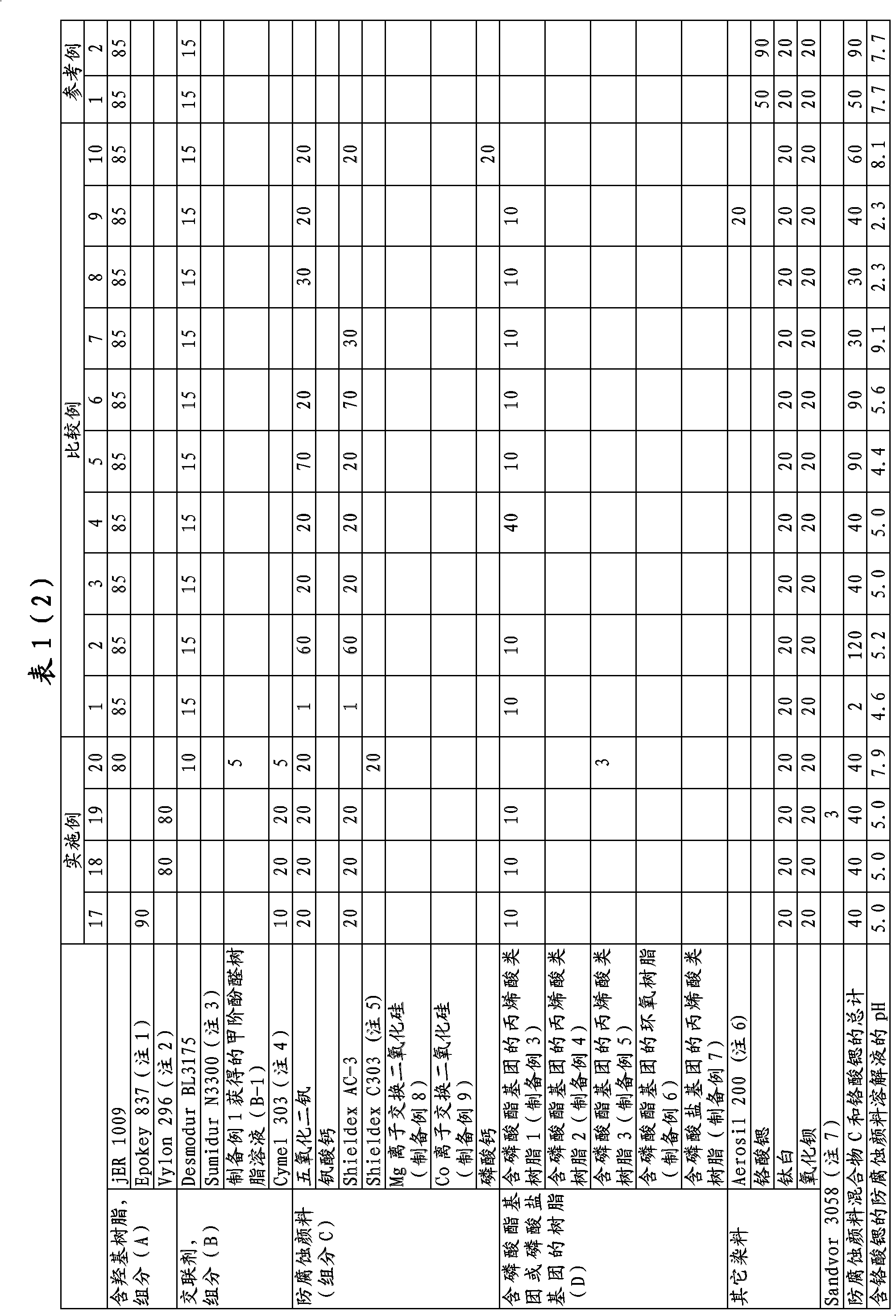

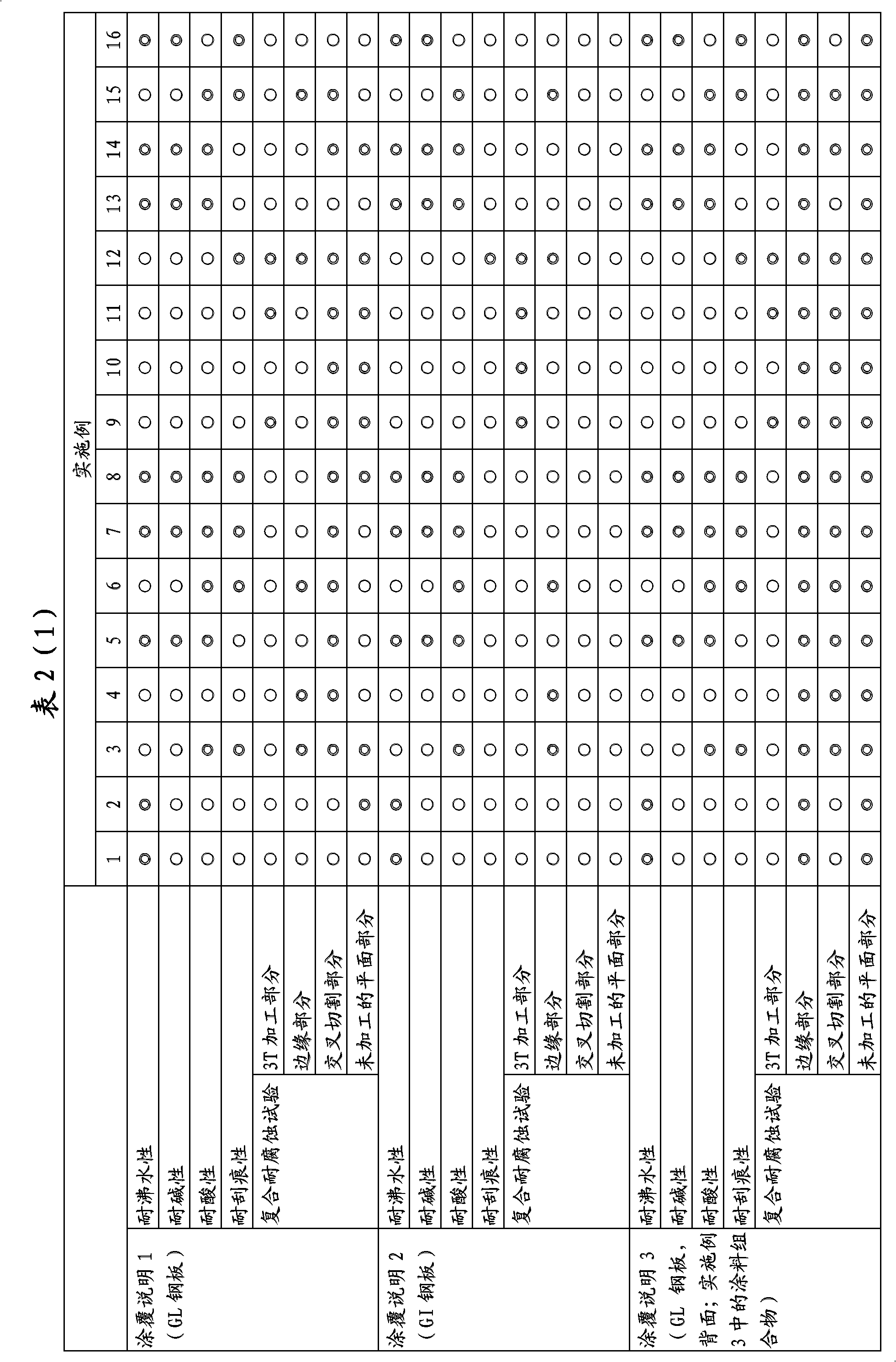

Examples

preparation example 1

[0113] Preparation of resole phenolic resin crosslinking agent solution:

[0114]Charge 100 parts of bisphenol A, 178 parts of 37% aqueous formaldehyde and 1 part of sodium hydroxide in a reaction vessel, then react at 60°C for 3 hours, dehydrate at 50°C for 1 hour under vacuum, add 100 parts of n-butanol and 3 parts of phosphoric acid, reacted at 110-120° C. for 2 hours, filtered the resulting solution, and filtered out the generated sodium phosphate to obtain a resole phenolic resin crosslinking agent solution B1 with a solid content of about 50%. The resin obtained as above had a number average molecular weight of 880, an average of 0.4 hydroxymethyl groups and an average of 1.0 alkoxymethyl groups per benzene ring, respectively.

preparation example 2

[0116] Preparation of coating composition for backside:

[0117] 200 parts were passed through 120 parts of mixed solvent 1 [cyclohexanone / ethylene glycol monobutyl ether / Solvesso 150 (trade name, Esso Standard Oil Co., Ltd. sold, high boiling point aromatic hydrocarbon solvent)=3 / 1 / 1 / weight ratio] in the epoxy resin solution prepared by dissolving 80 parts of jER 1009 (trade name, sold by Japan Epoxy Resins Co.Ltd., bisphenol A type epoxy resin, hydroxyl resin) and 40 parts of titanium dioxide, A mixture of 40 parts of barium oxide and a predetermined amount of mixed solvent 2 [Solvesso 150 (trade name, sold by Esso Standard Oil Co., Ltd., high-boiling aromatic hydrocarbon solvent) / cyclohexanone=1 / 1, weight ratio] Subject to pigment dispersion so that the particle size, i.e. the particle size of the coarse pigment particles, can be reduced to below 20 microns, then add 26.7 parts (20 parts in solids) of Desmodur BL-3175 (trade name, Sumika Bayer Urethane Co. , Ltd., methyl ...

preparation example 3

[0120] Preparation of acrylic resin 1 containing phosphate groups

[0121] Charge 100 parts of butanol into the reaction vessel, followed by dropwise addition of 50 parts of styrene, 35 parts of 2-ethylhexyl methacrylate, 15 parts of glycidyl methacrylate and 2.0 parts of 2,2' - A mixture of azobisisobutyronitrile while maintaining the reactor temperature at 110°C.

[0122] Then, add 0.5 parts of 2,2'-azobisisobutyronitrile, then react at 110°C for 2 hours, keep the reactor temperature at 80°C, slowly add 12.2 parts of 85% orthophosphoric acid and 10.4 parts of butanol and It was reacted for 1 hour until the turbidity of the mixture generated in the reactor disappeared to obtain a phosphate group-containing acrylic resin 1 solution having a solid content of 50%. The phosphate group-containing acrylic resin 1 had a resin acid value of 54 as a solid content (0.096 equivalent / 100 g of resin in terms of phosphate group content).

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com