Overlong carbon nanotubes and preparation method thereof

A technology of carbon nanotubes and hydrogen, which is applied in the field of carbon nanotubes and their preparation, ultra-long carbon nanotubes and their preparations, can solve problems such as gaps in electrical and mechanical properties, achieve perfect structure, high purity, and solve limited length Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

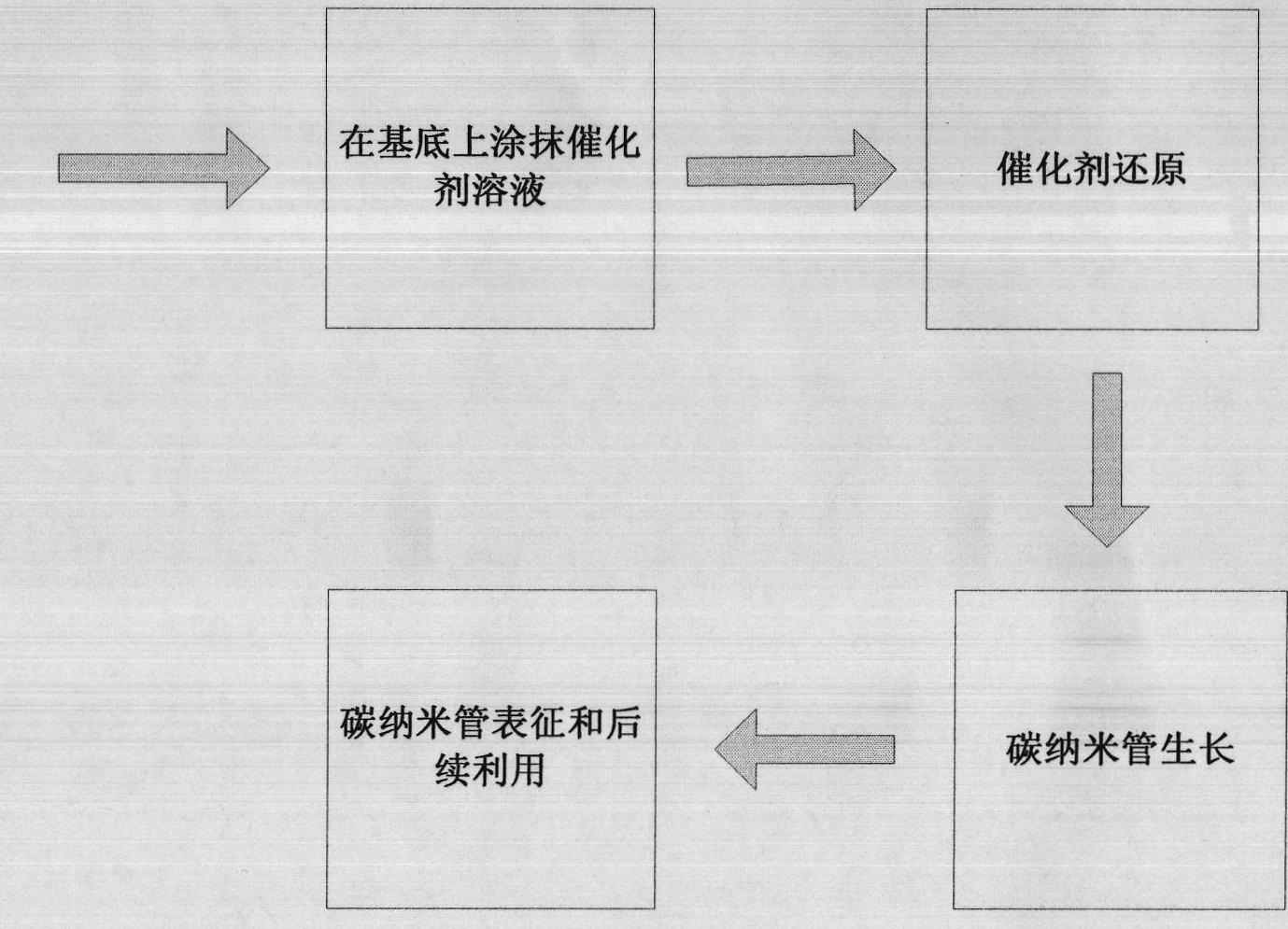

[0034] figure 1 It is a simple schematic flow diagram of the preparation method of the present invention: the ethanol solution or aqueous solution of at least one metal chloride in Fe, Mo, Cu, Cr is used as a catalyst solution, applied on the substrate, under the protection of hydrogen or hydrogen and an inert gas The reduction of the catalyst is carried out under the condition of the catalyst, and then the carbon source gas is passed through to carry out the reaction. Superlong carbon nanotubes with perfect structure can be prepared after 30 seconds to 5 hours.

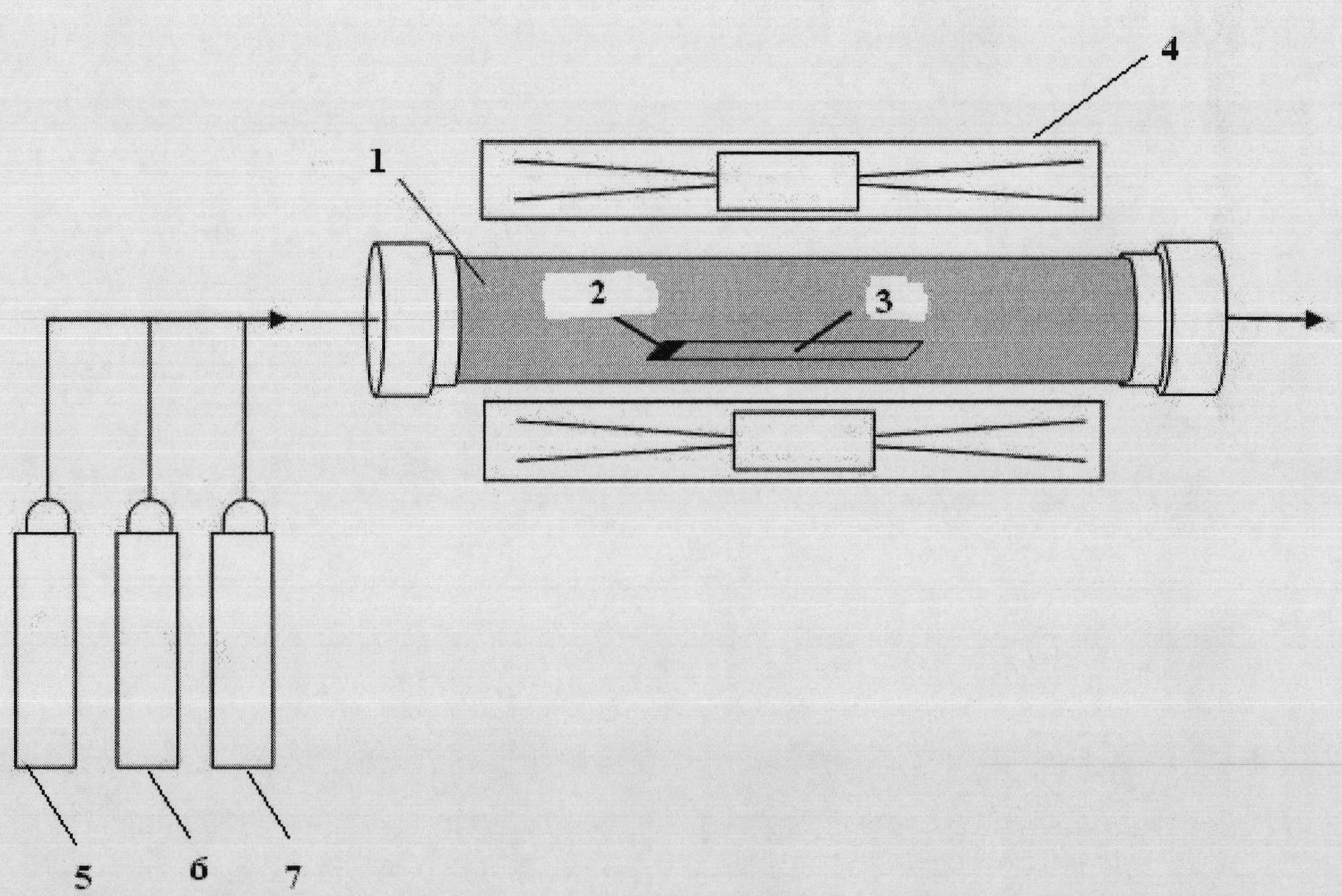

[0035] figure 2 It is a schematic diagram of the process device of Embodiment 1-3 of the present invention, and each label in the figure is as follows: 1 quartz tube, 2 catalyst, 3 substrate, 4 electric heating furnace, 5 Ar bottle, 6 methane gas bottle, 7 hydrogen gas bottle.

Embodiment 1

[0036] Embodiment 1, the preparation of ultra-long carbon nanotube

[0037] (1) FeCl with a concentration of 0.0001mol / L 3 The ethanol solution is applied on the substrate of the silicon wafer. The specifications of the silicon wafer are: the doping type is p-type, the crystal form is (111) type, and the resistivity is 10Ω·cm; the width is 1cm, the length is 10cm, and the surface has a thickness of 500nm. SiO 2 Oxide layer, SiO 2 The presence of the oxide layer can prevent Fe particles from reacting with the silicon wafer. Then coated with FeCl 3 The silicon wafer substrate of the ethanol solution is sent into the quartz tube reactor, such as figure 2 As shown, the inner diameter of the quartz tube is 31mm and the length is 1.5m.

[0038] (2) In the quartz tube reactor, feed the mixed gas of hydrogen and argon and heat the quartz tube reactor, control the flow rate of hydrogen to be 100ml / min, and the flow rate of argon to be 200ml / min; when the temperature rises to 900°...

Embodiment 2

[0042] Embodiment 2, preparation of ultra-long carbon nanotubes

[0043] (1) FeCl with a concentration of 0.04mol / L 3 and MoCl 3 The mixed ethanol solution (molar ratio: 1:1) was applied on the quartz substrate, and the quartz sheet was a curved sheet with a diameter of 5 cm and a length of 10 cm. The quartz substrate coated with the mixed ethanol solution is then fed into a quartz tube reactor as figure 2 As shown, the inner diameter of the quartz tube is 20mm and the length is 1.0m.

[0044] (2) In the quartz tube reactor, feed the mixed gas of hydrogen and argon and heat the quartz tube reactor, control the flow rate of hydrogen to be 200ml / min, and the flow rate of argon to be 100ml / min; when the temperature rises to 800°C , the reduction reaction was carried out at constant temperature for 25 minutes, and Fe particles and Mo particles with a particle size of nanometer were obtained, which had high catalytic activity.

[0045] (3) After the reduction reaction is over,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com