Method for preparing fluorine-containing acrylate copolymer textile finishing agent

A fabric finishing agent, acrylate technology, applied in fiber treatment, textiles and papermaking, etc., can solve the problems of the decline of water and oil repellency of copolymers, the increase of surface energy, the decrease of receding dynamic contact angle, etc., to achieve excellent water and oil repellency. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

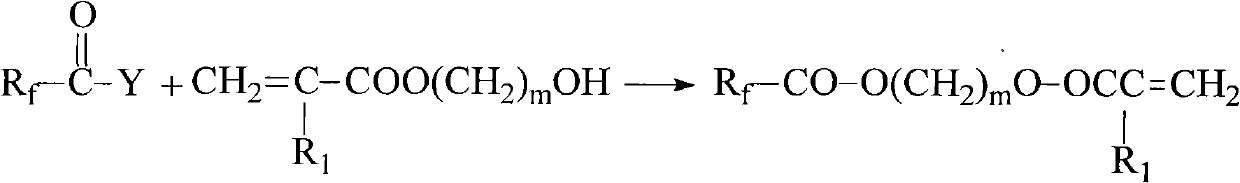

[0032] Preparation of perfluorobutyryloxyethyl acrylate

[0033] 13.19 g (0.114 mol) of hydroxyethyl acrylate, 9.57 g of pyridine, 65.95 g of dichloromethane and 0.013 g of phenothiazine were added to the flask with condenser. After cooling and keeping the temperature in the flask at 5°C, 22.15 g (0.095 mol) of perfluorobutyryl chloride was added dropwise. After the dropwise addition, it was stirred for another 30 minutes, then heated to 30° C. and stirred and refluxed for 2 hours. Then the mother liquor is poured into ice water, washed with ice water until the organic phase is neutral to obtain the crude product (a fluorine-containing acrylate dichloromethane solution containing a small amount of pyridine), which is subjected to vacuum distillation to obtain 25.62g perfluorobutyl acrylate Acyloxyethyl ester CF 3 CF 2 CF 2 COOCH 2 CH 2 OOCCH=CH 2 , yield 86.4%.

Embodiment 2

[0035] Preparation of perfluorocaproyloxyethyl methacrylate

[0036] Add 16.42g (0.126mol) of hydroxyethyl methacrylate, 15.38g of triethylamine, 42.84g of diethyl ether and 0.016g of phenothiazine into a flask with a condenser. Cool and keep the temperature in the flask at 0°C, and start dropping 35.64 g (0.107 mol) of perfluorohexanoyl chloride. After the dropwise addition, stir again for 1 h, raise the temperature to 40° C. and stir and reflux for 3 h. Then the mother liquor was poured into ice water, washed with ice water until the organic phase was neutral, and the crude product was obtained. After vacuum distillation, 35.58 g of perfluorocaproyloxyethyl methacrylate CF was obtained. 3 (CF 2 ) 4 COOCH 2 CH 2 OOCC (CH 3 )=CH 2 , yield 84.6%.

Embodiment 3

[0038] Preparation of 2-trifluoromethyl-3-oxa-octafluorohexanoyloxyethyl acrylate

[0039] 16.18g (0.139mol) hydroxyethyl acrylate, 19.14g N, N-dimethylaniline and 0.016g phenothiazine dissolved in 66.33g methylene chloride were added in the flask with condenser, cooled and kept at a temperature of At -15°C, 39.11 g (0.118 mol) of 2-trifluoromethyl-3-oxa-octafluorohexanoyl fluoride was added dropwise. After the dropwise addition, stir again for 1 h, raise the temperature to 35° C. and stir and reflux for 7 h. Then the mother liquor was poured into ice water, washed with water until the organic phase was neutral, and the crude product was obtained, which was then rectified under reduced pressure to obtain 44.79g of acrylic acid 2-trifluoromethyl-3-oxa-octafluorohexanoyloxy Ethyl CF 3 CF 2 CF 2 OCF (CF 3 ) COOCH 2 CH 2 OOCCH=CH 2 , yield 88.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com