Method for preparing SiO2-containing metal oxide composite film

A composite film and oxide technology, which is applied in anodic oxidation, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of battery efficiency decline and compound rate increase, and achieve the effect of convenient operation and simple and feasible process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Prepare N-type silicon wafers, go through the texturing process, rinse with ultrapure water, and blow dry;

[0030] 2. Silk-print Al slurry on the silicon wafer prepared in step 1, and then sinter it in a sintering furnace with a sintering peak temperature of 820°C and a time of 8s;

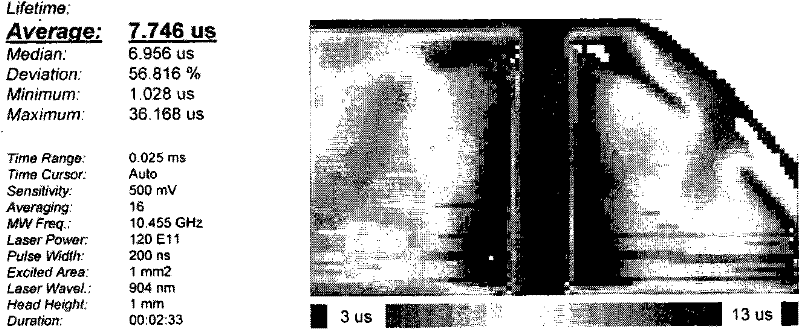

[0031] 3. Cut the silicon wafer prepared in step 2 into several small pieces, put them in a hydrochloric acid solution with a mass concentration of 37% and boil for 5 minutes to remove the Al layer and Al-Si alloy layer of the silicon wafer; then take out the silicon wafer and use Clean with ultrapure water and blow dry to obtain Al-doped P+ layer (effectively doped layer). Use Semilab WT2000 Minority Child Life Tester to test Minority Child Lifetime, the test results are as follows Figure 1a Shown

[0032] 4. The silicon wafer prepared in step 3 is etched in a potassium hydroxide solution with a mass concentration of 12% and a temperature of 55°C for 3 minutes to clean the surface traces of ...

Embodiment 2

[0039] 1. Prepare P-type silicon wafer, clean and blow dry according to standard RCA cleaning steps;

[0040] 2. Silk-print Al paste on the silicon wafer prepared in step 1, and then sinter it in a sintering furnace. The sintering peak temperature is 1050°C and the time is 2s;

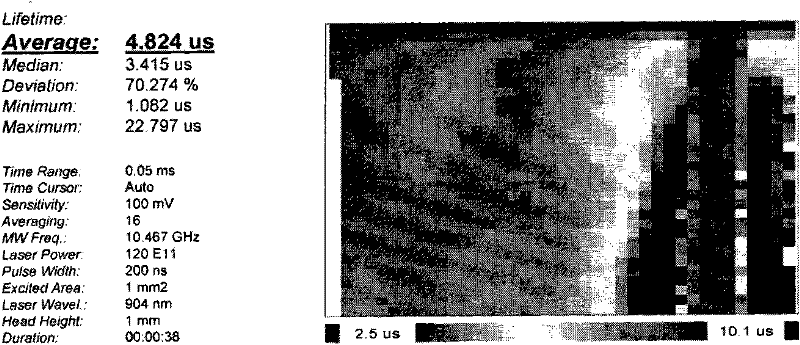

[0041] 3. Cut the silicon wafer prepared in step 2 into several small pieces, put them in a 10% phosphoric acid solution and react for 10 minutes at room temperature to remove the Al layer and Al-Si alloy layer of the silicon wafer; then take out the silicon wafer and use ultra-pure Wash with water and blow dry to obtain Al-doped P+ layer (effective doping layer). The semilab WT2000 minority carrier life tester is used to test the silicon wafer minority carrier lifetime, and the test results are as follows Figure 2a Shown

[0042] 4. Prepare 2 liters of nitric acid solution to be used as a conductive solution for anodizing process;

[0043] 5. Place the silicon wafer prepared in step 4 on the anode end of th...

Embodiment 3

[0047] 1. Prepare N-type silicon wafers, go through the texturing process, rinse with ultrapure water, and blow dry;

[0048] 2. Silk-print Al paste on the silicon wafer prepared in step 1, and then sinter the silicon wafer through a sintering furnace with a sintering peak temperature of 850°C and a time of 4s;

[0049] 3. Cut the silicon wafer prepared in step 2 into several small pieces, put them in a 10% hydrochloric acid solution and boil for 30 minutes to remove the Al layer and Al-Si alloy layer of the silicon wafer; then take out the silicon wafer and use super Clean with pure water and blow dry to obtain Al-doped P+ layer (effective doping layer);

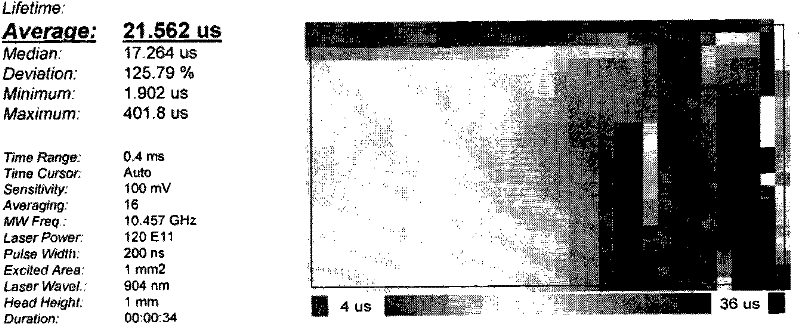

[0050] 4. Etch in a potassium hydroxide solution with a mass concentration of 15% and a temperature of 55°C for 20 seconds to clean the surface traces of the silicon wafer to obtain an Al-doped P+ inner layer (effectively doped layer inner layer). Use semilab WT2000 minority carrier lifetime tester to test the minority carrier li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com