Polyethylene terephthalate and polyurethane composite artificial blood vessel and preparation thereof

A polyethylene terephthalate and artificial blood vessel technology, which is applied in the field of biomedical engineering, can solve the problems of limited improvement of blood vessel elasticity and inability to meet the requirements for the use of small-diameter artificial blood vessels and long-term patency rate of large-diameter artificial blood vessels. , to achieve the effect of good elasticity and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] a solution preparation:

[0034] Dissolve 60-95 parts of polyethylene terephthalate and 5-40 parts of polyurethane in hexafluoroisopropanol solvent, stir until completely dissolved, and make a spinning stock solution with a mass fraction of 5-12% 4;

[0035] b Preparation of artificial blood vessels:

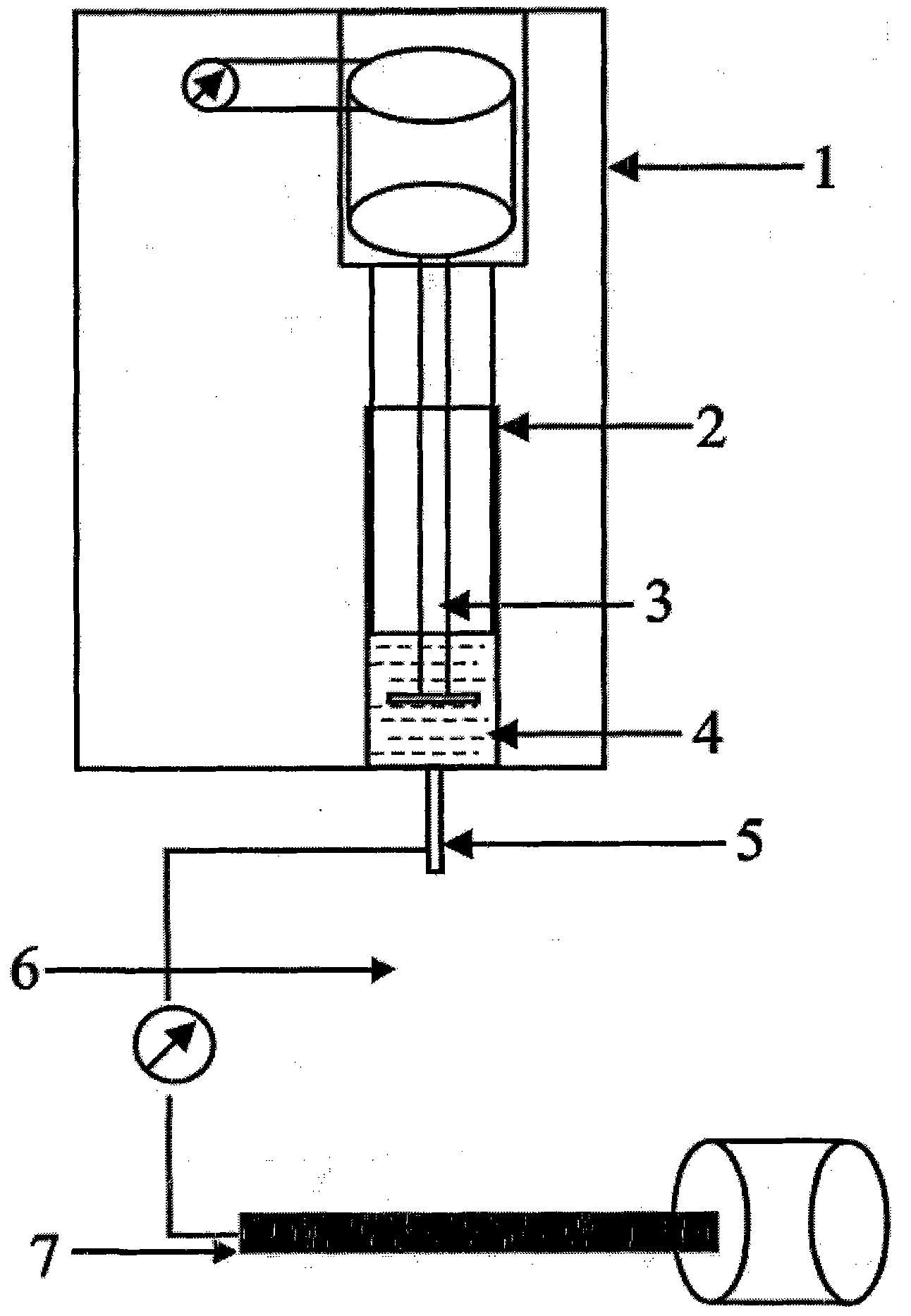

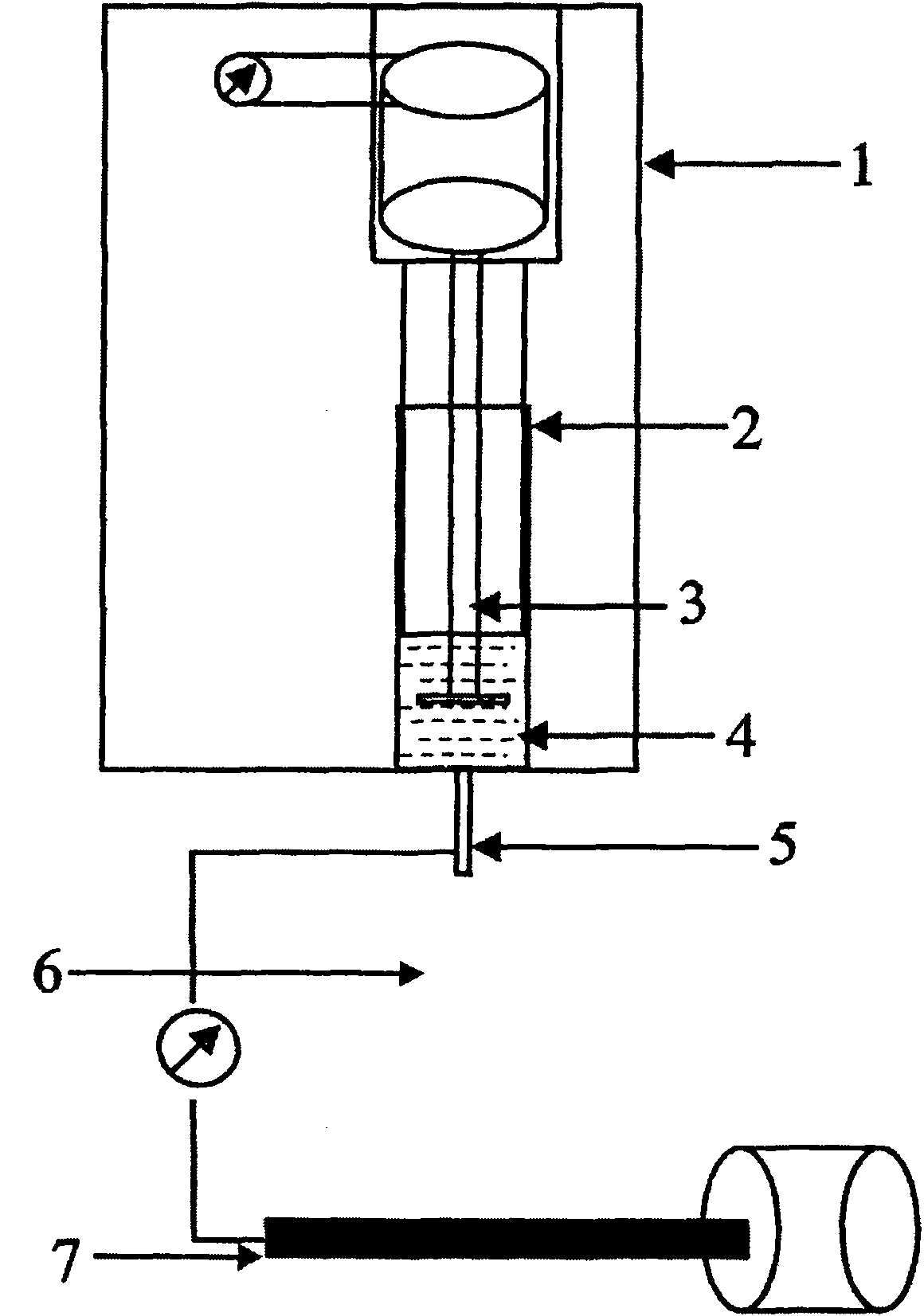

[0036]Put the spinning stock solution 4 prepared by a into the solution cylinder 2 of the electrospinning device with the agitator 3, place the agitator 3 in the solution cylinder 2, and the agitator 3 at a speed of 10 to 50 rpm Stir the spinning stock solution 4 so that the polyethylene terephthalate and polyurethane in the spinning stock solution 4 are evenly mixed, and the artificial blood vessel structure is formed using the drum mold 7 as a receiving device, and the drum mold 7 is located at the nozzle 5 of the electrospinning device Below, its axis is perpendicular to the nozzle 5 of the electrospinning device, the rotation speed of the drum mold 7 is 10 to 100 rp...

Embodiment 1

[0040] a Weigh 4.75g of polyethylene terephthalate and 0.25g of polyurethane (CorethaneTM) on a precision electronic balance, and fully dissolve them in 95g of hexafluoroisopropanol to obtain a spinning stock solution with a concentration of 5%. Wherein the mass ratio between polyethylene terephthalate and polyurethane is 95 / 5.

[0041] The spinning stock solution prepared by b is added to the solution tank for electrospinning, and the agitator stirs the spinning stock solution at a speed of 10 rpm. The drum mold with a diameter of 1 mm is selected as the collecting device, and the rotation speed of the drum mold is set to be 10 revolutions / min, the speed of linear reciprocating motion is 100mm / min. The micro-injection pump pushes the evenly stirred spinning stock solution through the nozzle into the high-voltage electric field with a voltage of 15KV and an electric field distance of 50mm at a propulsion speed of 0.1ml / h. Fiber 6h, forming an artificial blood vessel structure...

Embodiment 2

[0044] a Weigh 8g polyethylene terephthalate and 2g polyurethane ( 80A), fully dissolved in 90g hexafluoroisopropanol to obtain a spinning dope with a concentration of 10%. Wherein the mass ratio between polyethylene terephthalate and polyurethane is 80 / 20.

[0045] The spinning stock solution prepared by b is added to the solution cylinder for electrospinning, and the agitator stirs the spinning stock solution at a speed of 50 rpm. The drum mold with a diameter of 30 mm is selected as the collection device, and the rotation speed of the drum mold is set to be 100 revolutions / min, the speed of linear reciprocating motion is 500mm / min. The micro-injection pump pushes the evenly stirred spinning stock solution through the nozzle into the high-voltage electric field with a voltage of 25KV and an electric field distance of 300mm at a propulsion speed of 0.1ml / h. Fiber 6h, forming an artificial blood vessel structure with an inner diameter of 30 mm and a wall thickness of 100 μm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com