Composition of super large mode area silicate fiber and method of producing the same

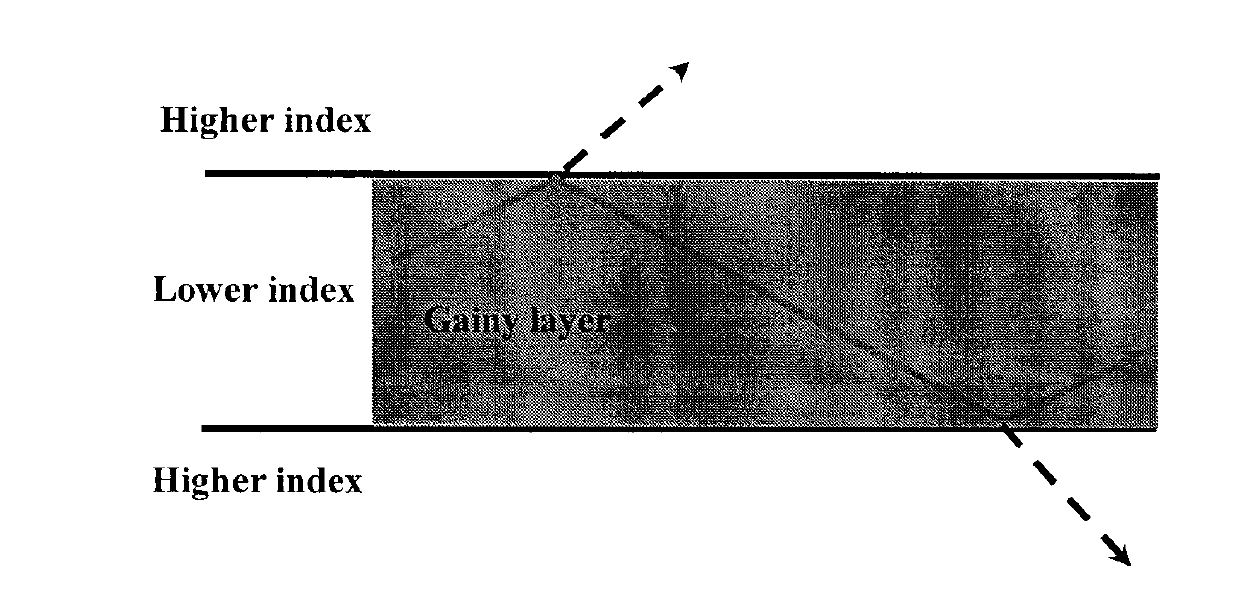

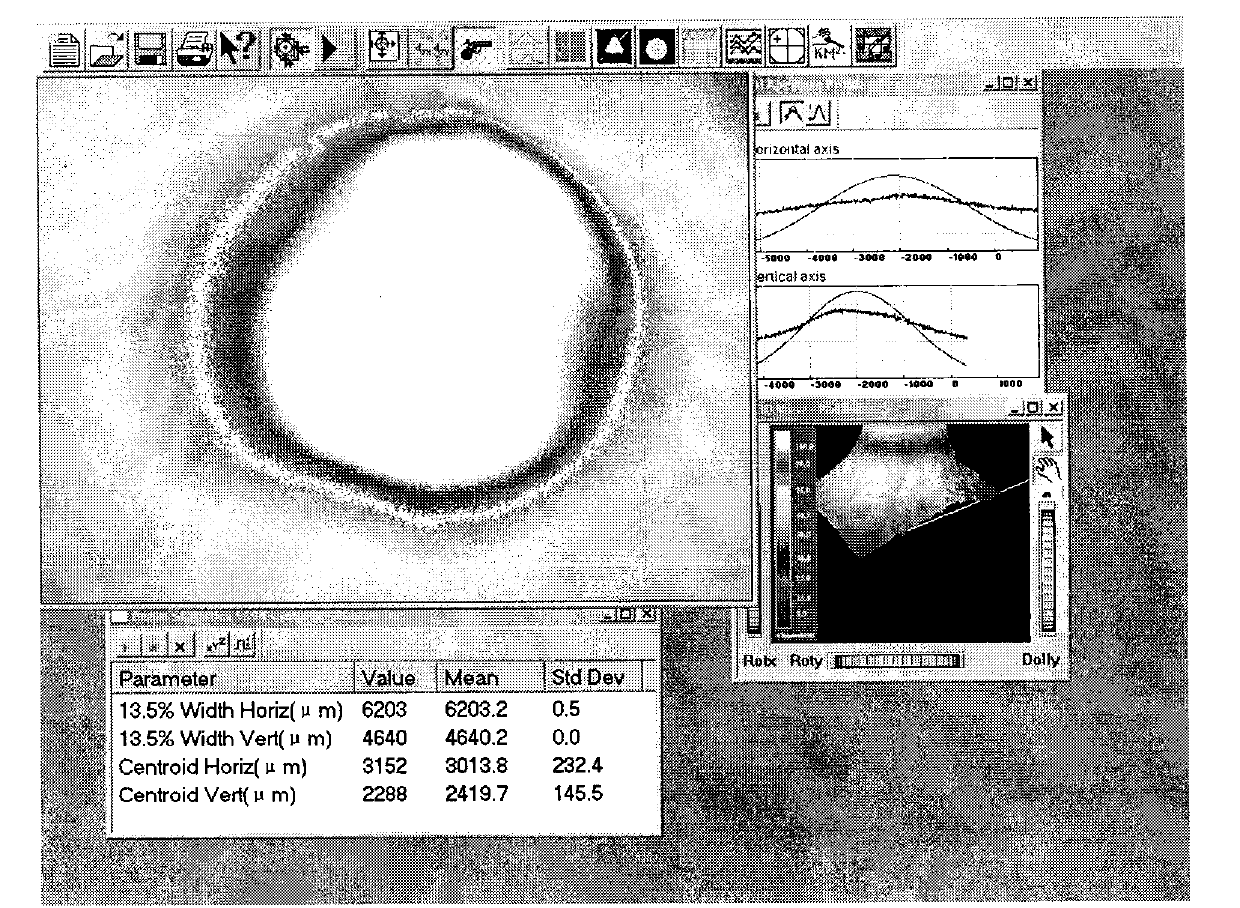

A silicate and optical fiber technology, applied in clad optical fiber, glass manufacturing equipment, optics, etc., can solve the problem that the optical fiber cannot meet the mode field diameter of 100 μm or more and single-mode transmission characteristics at the same time, and achieve the effect of excellent thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] According to the structural characteristics of GG+IAG optical fiber, take the first group of formulas in Table 1-1 and Table 1-2 for processing.

[0084] In the raw materials, silicon oxide, aluminum oxide, and lead oxide are introduced in the form of oxides, boron oxide is introduced in boric acid, potassium oxide is introduced in potassium nitrate, and the purity of each oxide or compound is greater than 99.6%; the purity of lanthanum oxide and yttrium oxide is greater than 99.99%, The rare earth oxide is any one of ytterbium oxide, erbium oxide, neodymium oxide or thulium oxide, preferably ytterbium oxide, with a purity greater than 99.99%. Yb3+ doped silicate glass was prepared by high temperature melting process.

[0085] After mixing the raw materials evenly, add them to the quartz crucible and heat them one by one. The heating temperature is 910°C and the heating time is 1.0h, and then pour the melt into the Pt crucible for heating. , clarification, and homogeni...

Embodiment 2

[0091] According to the structural characteristics of GG+IAG optical fiber, take the sixth group formula in Table 1-1 and Table 1-2 for processing.

[0092] In the raw materials, silicon oxide, aluminum oxide, and lead oxide are introduced in the form of oxides, boron oxide is introduced in boric acid, potassium oxide is introduced in potassium nitrate, and the purity of each oxide or compound is greater than 99.6%; the purity of lanthanum oxide and yttrium oxide is greater than 99.99%, The rare earth oxide is any one of ytterbium oxide, erbium oxide, neodymium oxide or thulium oxide, preferably ytterbium oxide, with a purity greater than 99.99%. Yb3+ doped silicate glass was prepared by high temperature melting process.

[0093] After mixing the raw materials evenly, add them to the quartz crucible and heat them one by one. The heating temperature is 940°C and the heating time is 1.5h, and then pour the melt into the Pt crucible for heating. , clarification, and homogenizati...

Embodiment 3

[0099] According to the structural characteristics of GG+IAG optical fiber, take the formula of Group 10 in Table 1-1 and Table 1-2 for processing.

[0100] In the raw materials, silicon oxide, aluminum oxide, and lead oxide are introduced in the form of oxides, boron oxide is introduced in boric acid, potassium oxide is introduced in potassium nitrate, and the purity of each oxide or compound is greater than 99.6%; the purity of lanthanum oxide and yttrium oxide is greater than 99.99%, The rare earth oxide is any one of ytterbium oxide, erbium oxide, neodymium oxide or thulium oxide, preferably ytterbium oxide, with a purity greater than 99.99%. Yb3+ doped silicate glass was prepared by high temperature melting process.

[0101] After mixing the raw materials evenly, add them to the quartz crucible and heat them one by one. The heating temperature is 960°C and the heating time is 1.5h, and then pour the melt into the Pt crucible for heating. , clarification, and homogenizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com