Method for processing tail gas and dust generated by producing trichlorosilane

A trichlorosilane and treatment method technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve problems such as air pollution and large void ratio, and achieve water saving, high work efficiency, and nitrogen consumption saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

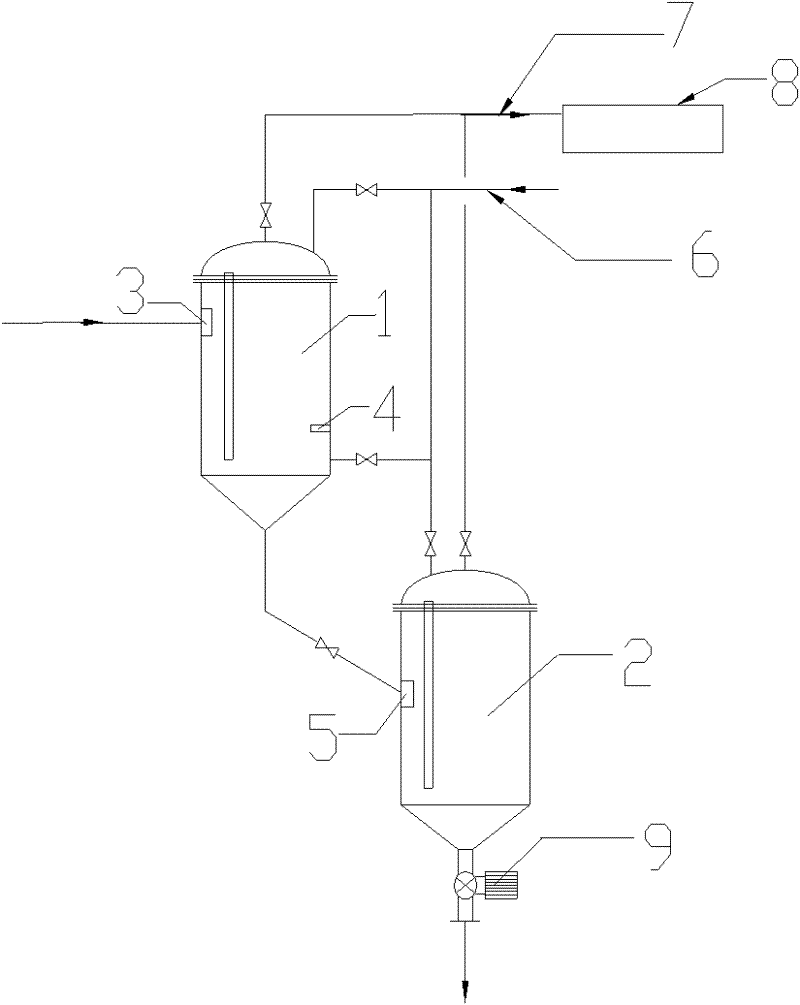

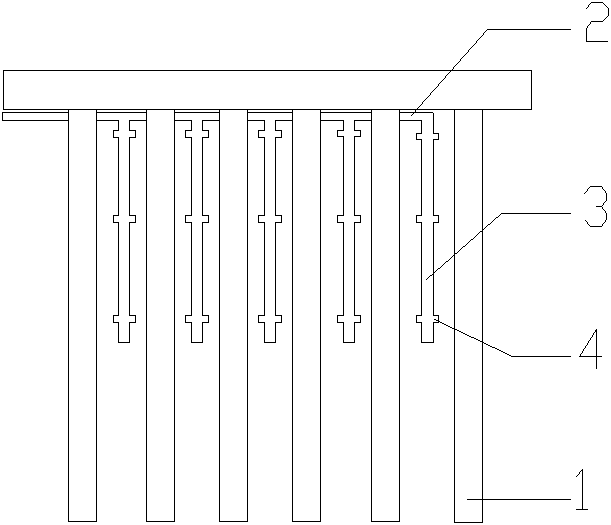

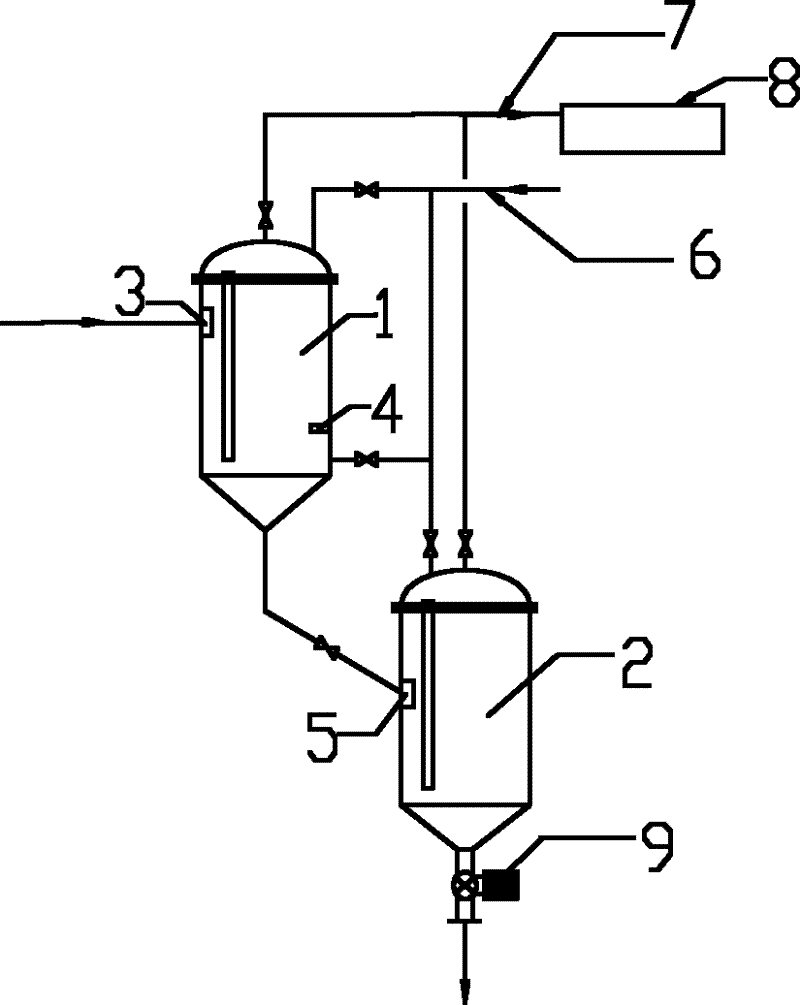

[0043] The treatment method of tail gas dust in the production process of trichlorosilane, the tail gas and dust in the production process of trichlorosilane first pass through the cyclone separator, and the tail gas dust separated by the cyclone separator is first collected by the filter device to obtain dust, and the dust passes through two Step bag filter treatment, in the bag filter, a cloth bag blowpipe is set to blow out nitrogen, and the cloth bag blowpipe is installed on the main pipe by the main pipe arranged at the bottom of the filter and parallel to the filter bag and the filter bag. The branch pipe between the pipes and the nozzles arranged on the branch pipes; the branch pipes are distributed in the gaps between all the filter bags, so that all the bags can be blown by the branch pipes, and the height of the branch pipes is 1 / 2 from the bottom to the top of the bag. Four nozzles are evenly arranged vertically on the branch pipe, the time for blowing nitrogen is 1-...

Embodiment 2

[0047] The treatment method of tail gas dust in the production process of trichlorosilane, the tail gas dust in the production process of trichlorosilane first passes through the cyclone separator, and the tail gas dust separated by the cyclone separator is first collected by the filter device to obtain dust, and the dust passes through the two-step bag In the two bag filters, there are cloth bag blowpipes, and the bag blowpipes blow out nitrogen to blow off the dust deposited on the bags. The main pipe is parallel to the branch pipe between the filter bags and the nozzles arranged on the branch pipe; the branch pipe is distributed in the gap between all the filter bags, so that all the cloth bags can be blown by the branch pipe, and the height of the branch pipe is At the upper 1 / 3 from the bottom to the top of the cloth bag, 5 nozzles are arranged vertically and evenly on the branch pipe, the time for nitrogen blowing is 1 second, the frequency of nitrogen blowing is 60 times...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com