Non-viral vector, and preparation method and application thereof

A non-viral vector and reaction technology, applied in the fields of polymer chemistry and biomedical engineering, can solve the problems of high cytotoxicity and immunogenicity, unsustainable high-efficiency expression, low transfection and expression efficiency, and increase expression efficiency , good particle uniformity, reducing the effect of non-specific adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1, compound shown in preparation formula I

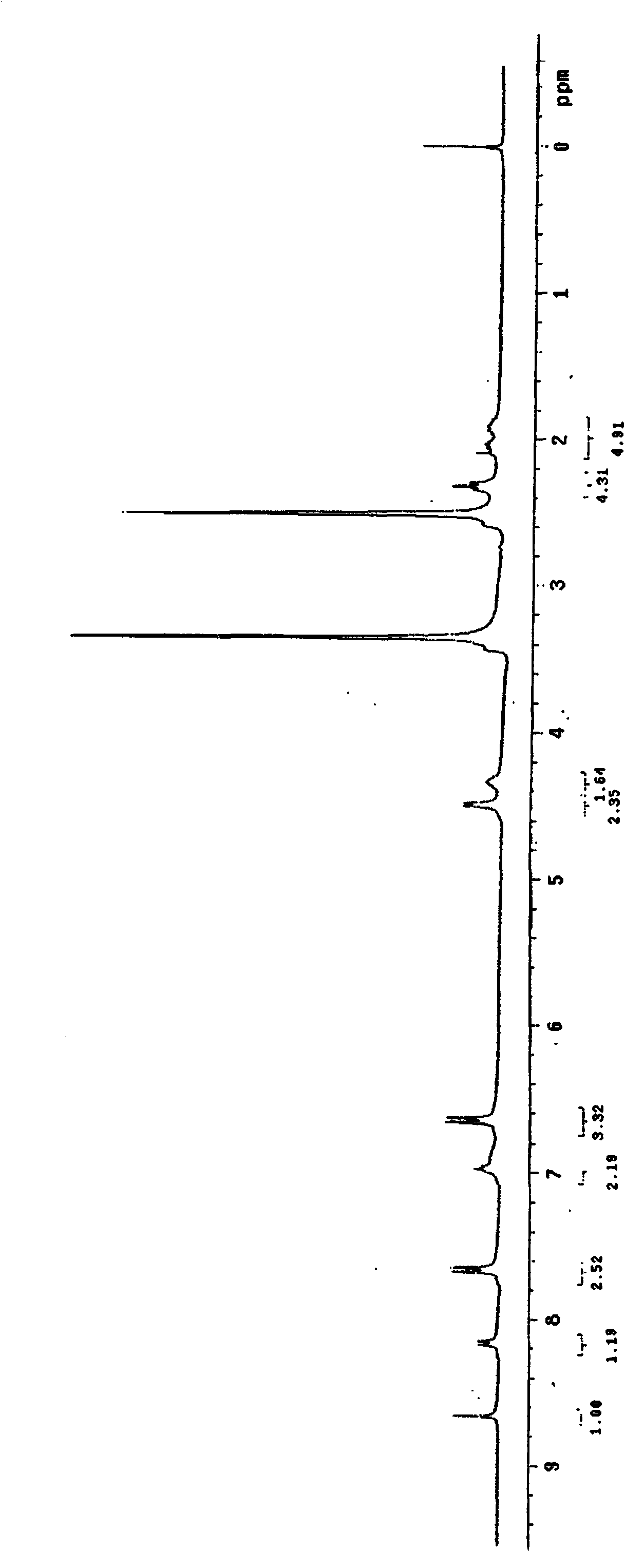

[0064] Since commercially available folic acid products contain considerable impurities, their NMR characterization is as follows: figure 1 As shown, before the preparation, the folic acid was first recrystallized according to the following steps: Dissolve 5.0g of folic acid raw material in 400mL of 0.2N NaOH aqueous solution, heat to boiling, and completely dissolve the folic acid, the solution is orange-yellow, keep the solution Slowly add 1N hydrochloric acid aqueous solution to the pH value of 5, some precipitates are separated out, cooled, centrifuged (centrifugal speed is 3800rpm, centrifugation time is 5min), remove viscous brown insoluble matter, continue to heat the remaining liquid, and then The pH value was adjusted to 3 with the above dilute hydrochloric acid, and after overnight cooling, the product was obtained by filtration, washed twice with pure water and twice with ethanol, and dried in vacuum to ...

Embodiment 2

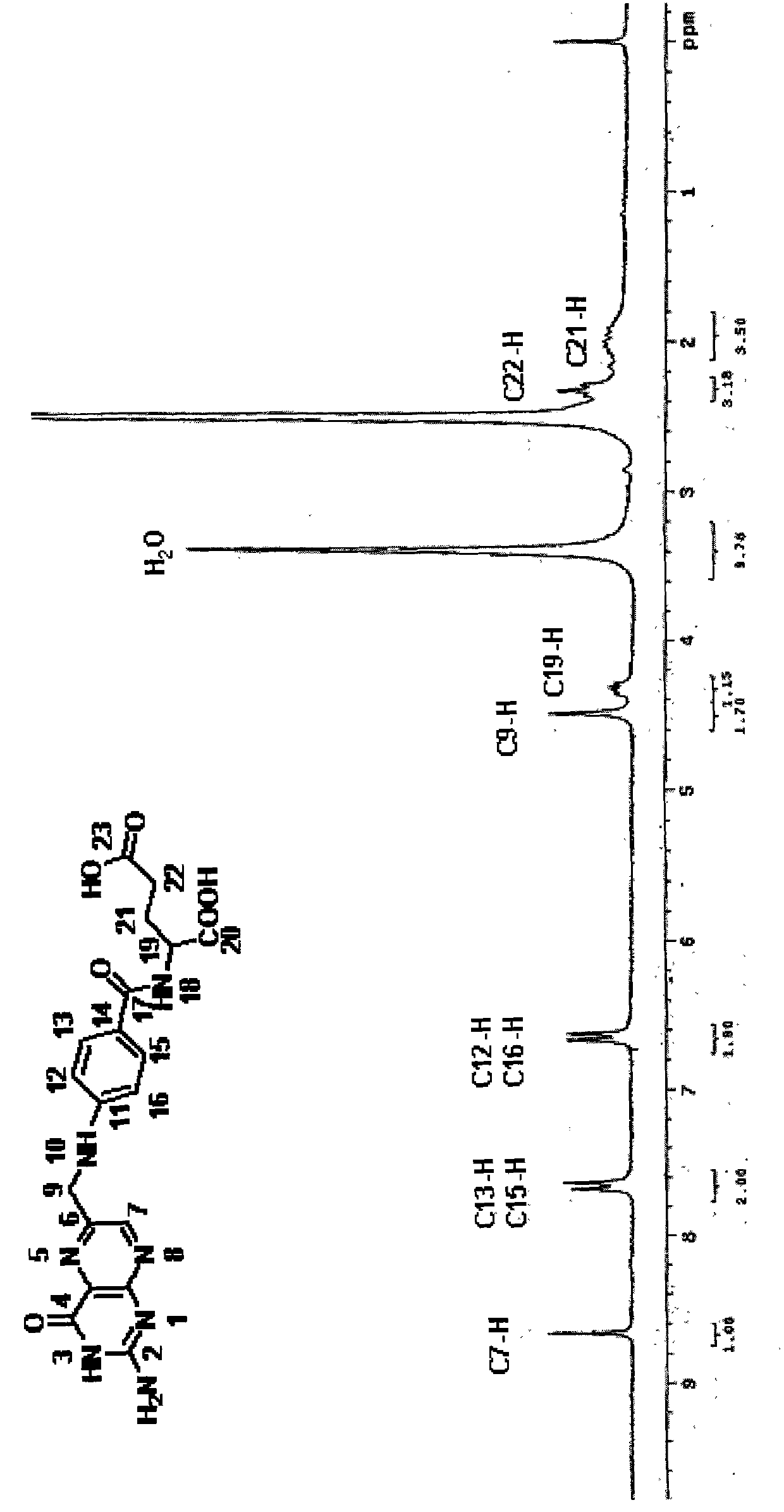

[0068] Embodiment 2, compound shown in preparation formula II

[0069] Take 0.3g (0.56mmol) of the compound (FA-NHS) shown in formula I prepared in Example 1, dissolve it in 15mL of anhydrous DMSO, then add 3mL of anhydrous triethylamine, add 70mg (0.62mmol) of 2-mercaptoethane Amine hydrochloride, N sparged 2 , 28 ℃ dark reaction 18h. The solution was sunk in anhydrous acetonitrile and filtered. Redissolve in DMSO, sink in diethyl ether twice, and dry in vacuo to obtain 0.21 g of bright yellow solid powder with a yield of 75%.

[0070] For the NMR characterization of the product, see Figure 4 . It can be seen from the figure that the structure of the compound is correct.

Embodiment 3

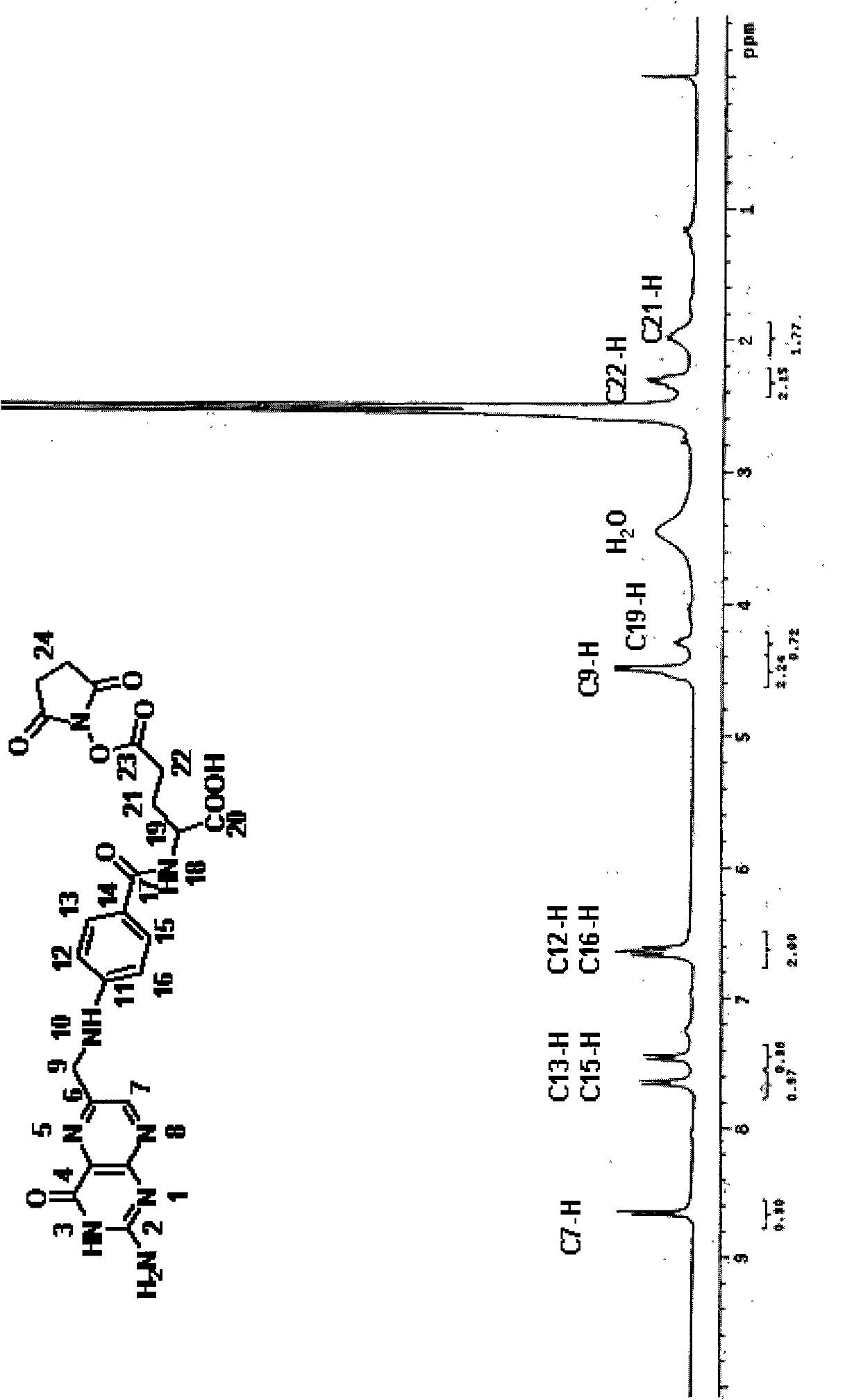

[0071] Embodiment 3, compound shown in preparation formula III

[0072] 200 mg (0.057 mmol) of the compound shown in Formula IV (Mal-PEG-NHS) with a molecular weight of 3500 Da was dissolved in 8 mL of PBS, and then 56 mg (0.115 mmol) of the compound shown in Formula II prepared in Example 2 was dissolved in 8 mL of PBS solution, the above two solutions in N 2 Mix under atmosphere, add a drop of triethylamine Et 3 N, sealed and reacted in a system with phosphate buffer solution as the reaction medium, and reacted at 35°C for 48h. The pH value of this phosphate buffer solution is 7.2-7.4, wherein, the concentration of NaCl is 137mmol / L, and the concentration of KCl is 2.7mmol / L, NaCl 2 HPO 4 The concentration is 4.3mmol / L, KH 2 PO 4 The concentration is 1.4mmol / L. After the reaction was completed, the system was freeze-dried, added with chloroform, filtered, and the organic phase was concentrated and sunk in cold ether to obtain 0.16 g of milky white solid powder with a y...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com