Method for detecting microalgae oil

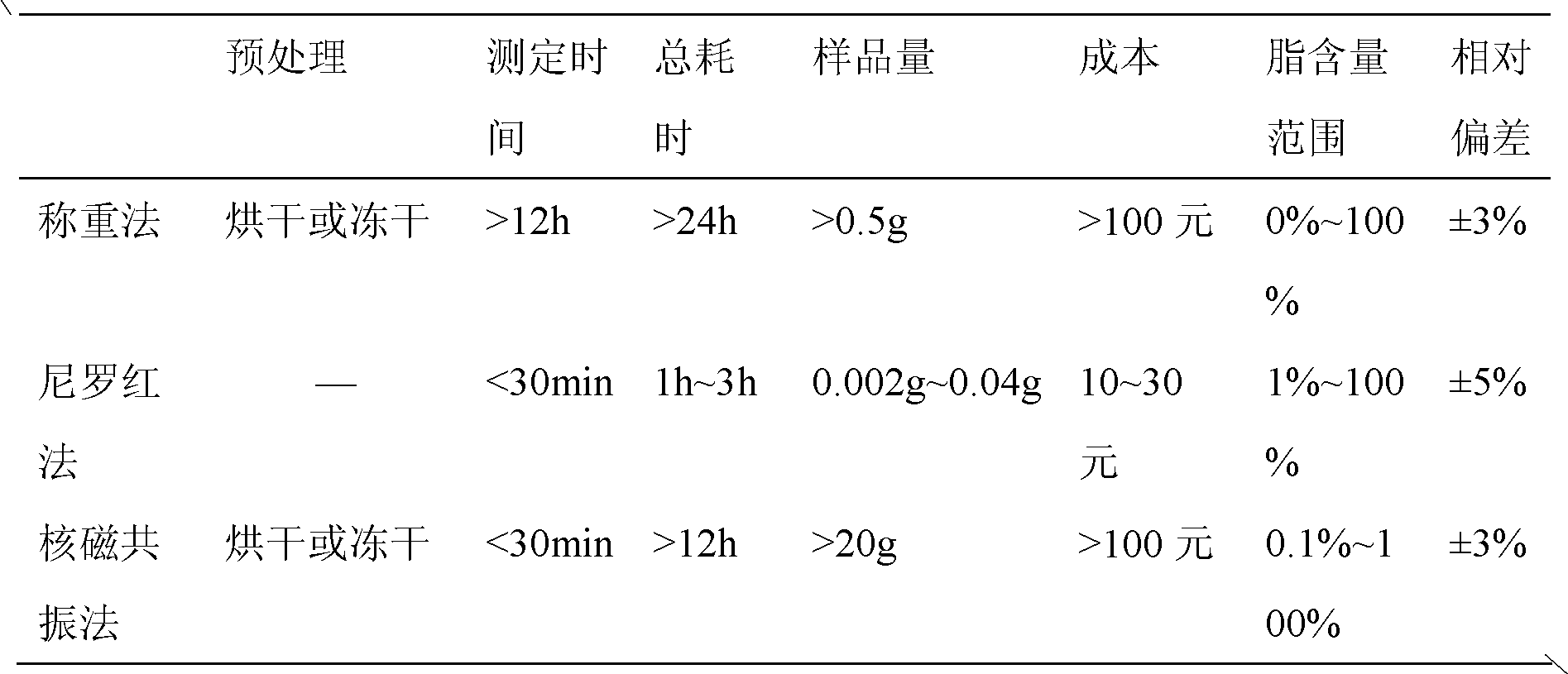

A technology of microalgae oil and detection method, which is applied in the preparation of test samples, fluorescence/phosphorescence, material excitation analysis, etc. The effect of reducing the total consumption time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

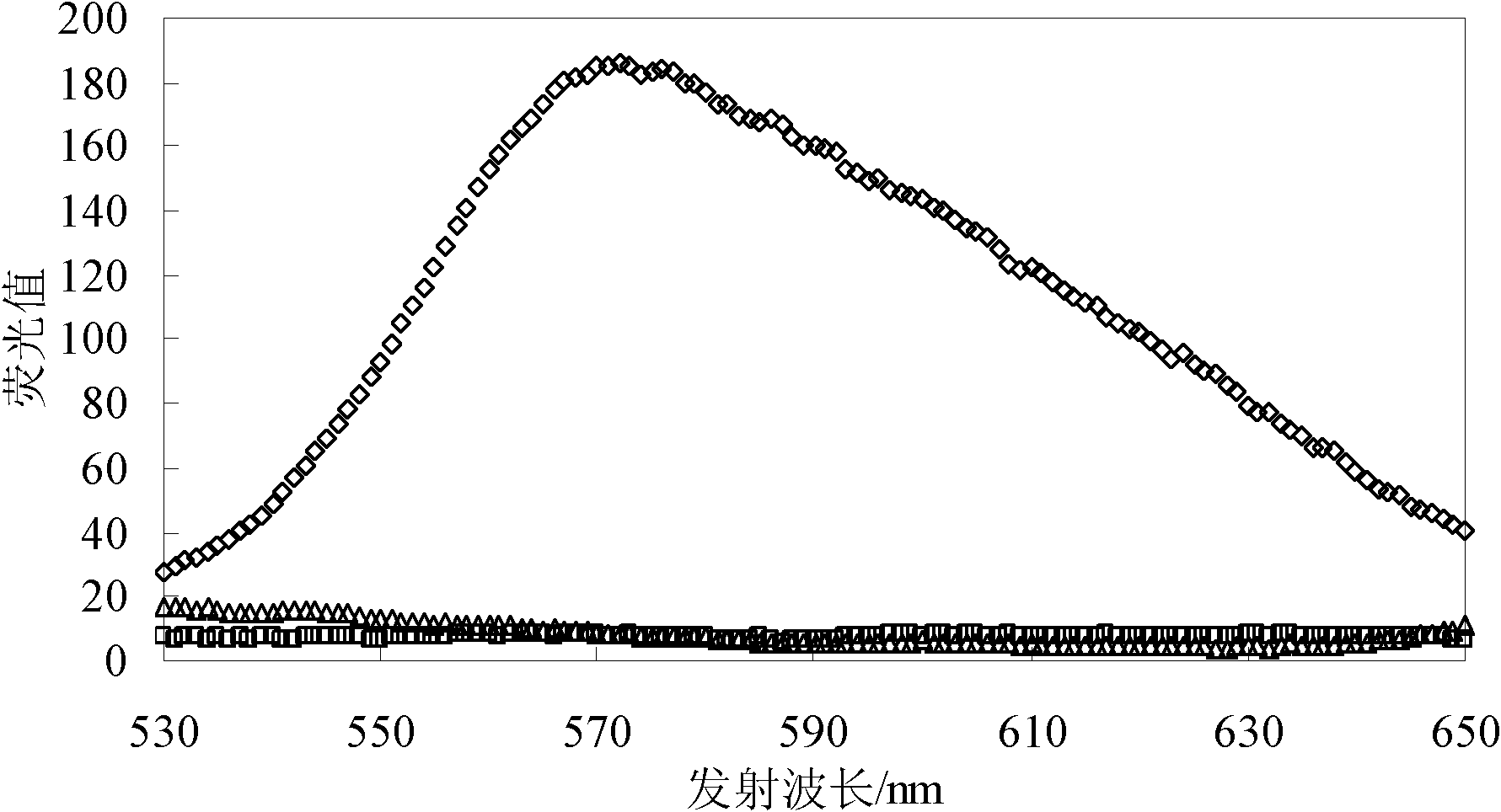

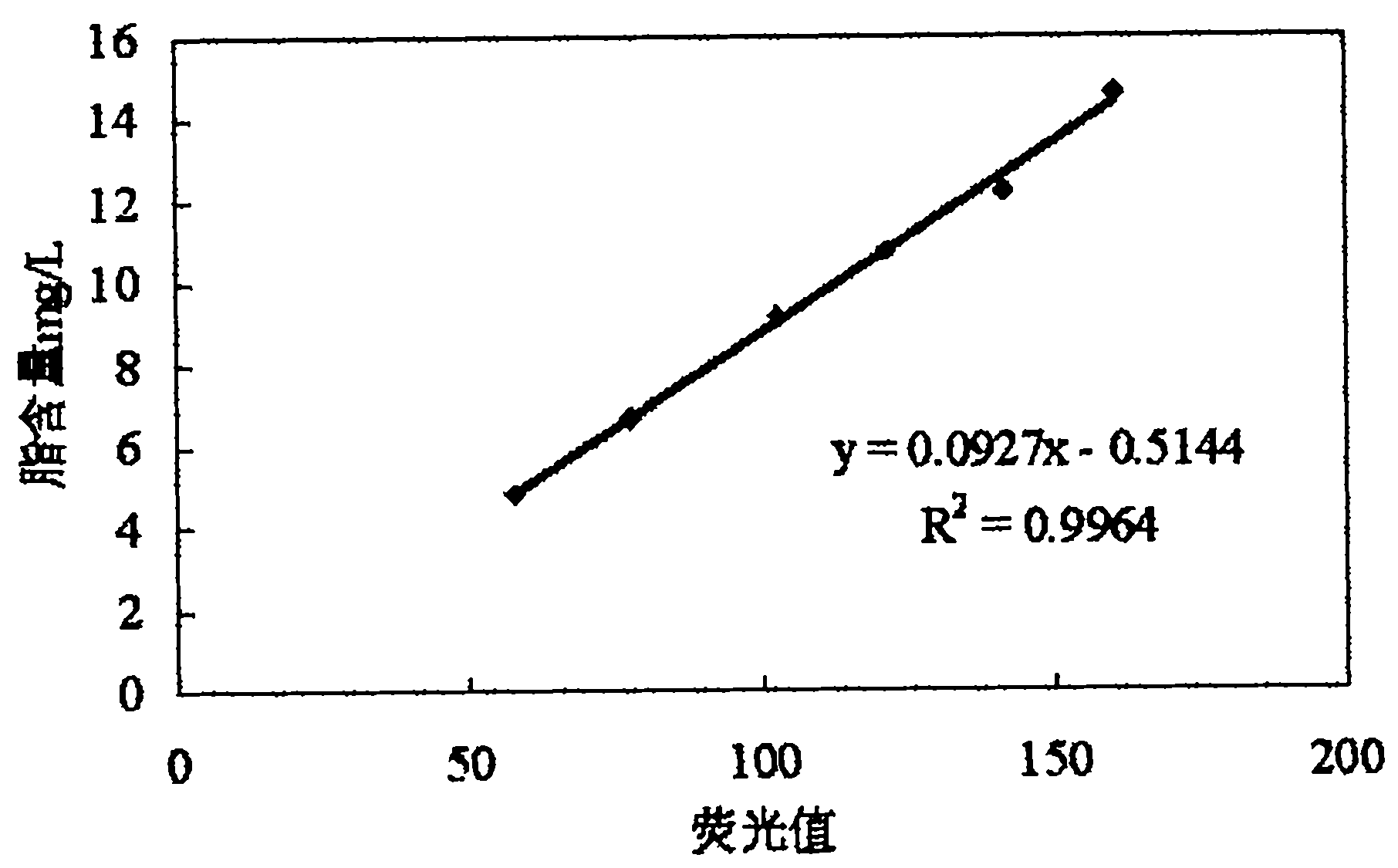

[0010] Embodiment 1: The detection method of microalgae oil in this embodiment is carried out according to the following steps: 1. Dilute the microalgae culture solution to 0.05g / L~0.5g / L to obtain the dilution; 2. Take 10mL Add 100 μL of Nile Red solution to the diluent in step 1, stain in the dark, select 400-600 nm as the excitation wavelength, measure the fluorescence intensity between the emission wavelength 450-700 nm, and record the fluorescence intensity as X1; Centrifuge the diluted solution for 10 minutes at a temperature of 4°C and a rotational speed of 10,000 r / min, take the supernatant as a blank, take 10 mL of the supernatant, add 100 μL of Nile Red solution, and stain in the dark, choose 400-600 nm As the excitation wavelength, measure the fluorescence intensity between the emission wavelength 450-700nm, and record the fluorescence intensity as X2; 4. Take the diluent in step 1, select 400-600nm as the excitation wavelength, and measure the fluorescence intensity...

specific Embodiment approach 2

[0011] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the solvent used to dilute the solution containing microalgae in step 1 is distilled water, tap water, deionized water, ultra-clean water or mineral water. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Specific embodiment three: this embodiment is different from specific embodiment one or two in that: the solvent of the Nile red solution described in step two is acetone, ethanol, propanol, dioxane, tetrahydrofuran or methyl ethyl ketone. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com