Hydroxyapatite/silk fibroin composite material and preparation method thereof

A technology of hydroxyapatite and silk fibroin, which is applied in the field of medical materials, can solve the problems of insufficient mechanical strength, poor degradability and toughness, insufficient mechanical properties, etc., and achieves improved mechanical properties, improved mechanical properties, and good practicability. and the effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

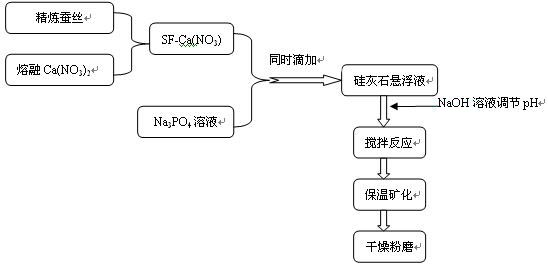

[0022] Embodiment one: see attached figure 1 , the present embodiment provides a preparation method of hydroxyapatite-wollastonite / silk fibroin composite biomimetic material, the steps are as follows:

[0023] 1. Prepare the concentration of 0.5mol / LCa (NO 3 ) 2 solution and Na 2 SiO 3 solution, the mass fraction of 0.5% polyvinyl alcohol solution was added to Ca(NO 3 ) 2 To the solution, Na was added dropwise while stirring 2 SiO 3 solution. After fully reacting, the obtained precipitate is washed with deionized water and absolute ethanol, dried and calcined to obtain wollastonite powder.

[0024] 2. According to the mass percentages of silk fibroin, wollastonite, and hydroxyapatite in the composite powder being 30%, 20%, and 50% respectively, to prepare 10g of composite powder, 3g of degummed silk should be weighed to obtain silk fibroin fiber and 2g wollastonite powder, and 11.76g Ca(NO 3 ) 2 4H 2 O and 11.36 g Na 3 PO 4 12H 2 O; Na 3 PO 4 12H 2 O is adde...

Embodiment 2

[0029] Embodiment 2: This embodiment provides a method for preparing a hydroxyapatite-wollastonite / silk fibroin composite biomimetic material, the steps of which are as follows:

[0030] 1. Prepare the concentration of 0.5mol / LCa (NO 3 ) 2 solution and Na 2 SiO 3 solution, the mass fraction of 0.5% polyvinyl alcohol solution was added to Ca(NO 3 ) 2 To the solution, Na was added dropwise while stirring 2 SiO 3 solution. After fully reacting, the obtained precipitate is washed with deionized water and absolute ethanol, dried and calcined to obtain wollastonite powder.

[0031] 2. According to the mass percentages of silk fibroin, wollastonite and hydroxyapatite in the composite powder being 30%, 30% and 40% respectively, to prepare 10g of composite powder, it is necessary to weigh 3g of silk degummed Silk fibroin fiber and 3g wollastonite powder, and 9.41g Ca(NO 3 ) 2 4H 2 O and 9.09 g Na 3 PO 4 12H 2 O; Na 3 PO 4 12H 2 O adds 50ml deionized water and is mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com