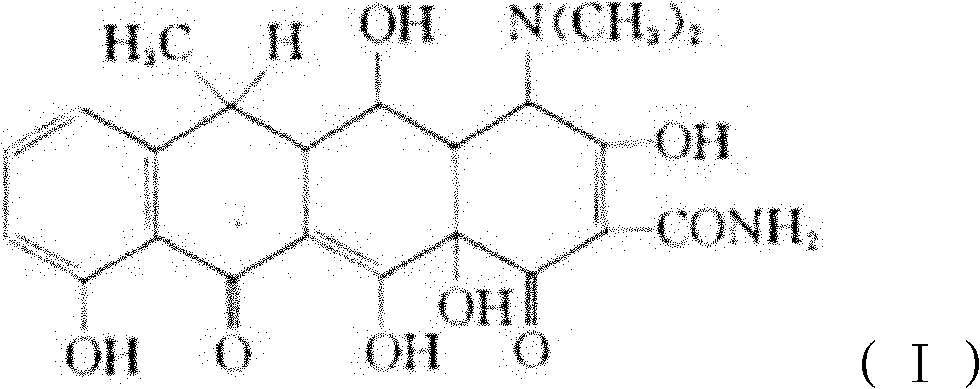

Filter medium for removing oxytetracycline in drinking water and preparation method thereof

A filter medium, oxytetracycline technology, applied in chemical instruments and methods, other chemical processes, water/sewage treatment, etc., can solve the problems of poor adsorption effect than activated carbon, cumbersome process, inconvenient use, etc., to achieve good adsorption effect, good Adsorption capacity, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

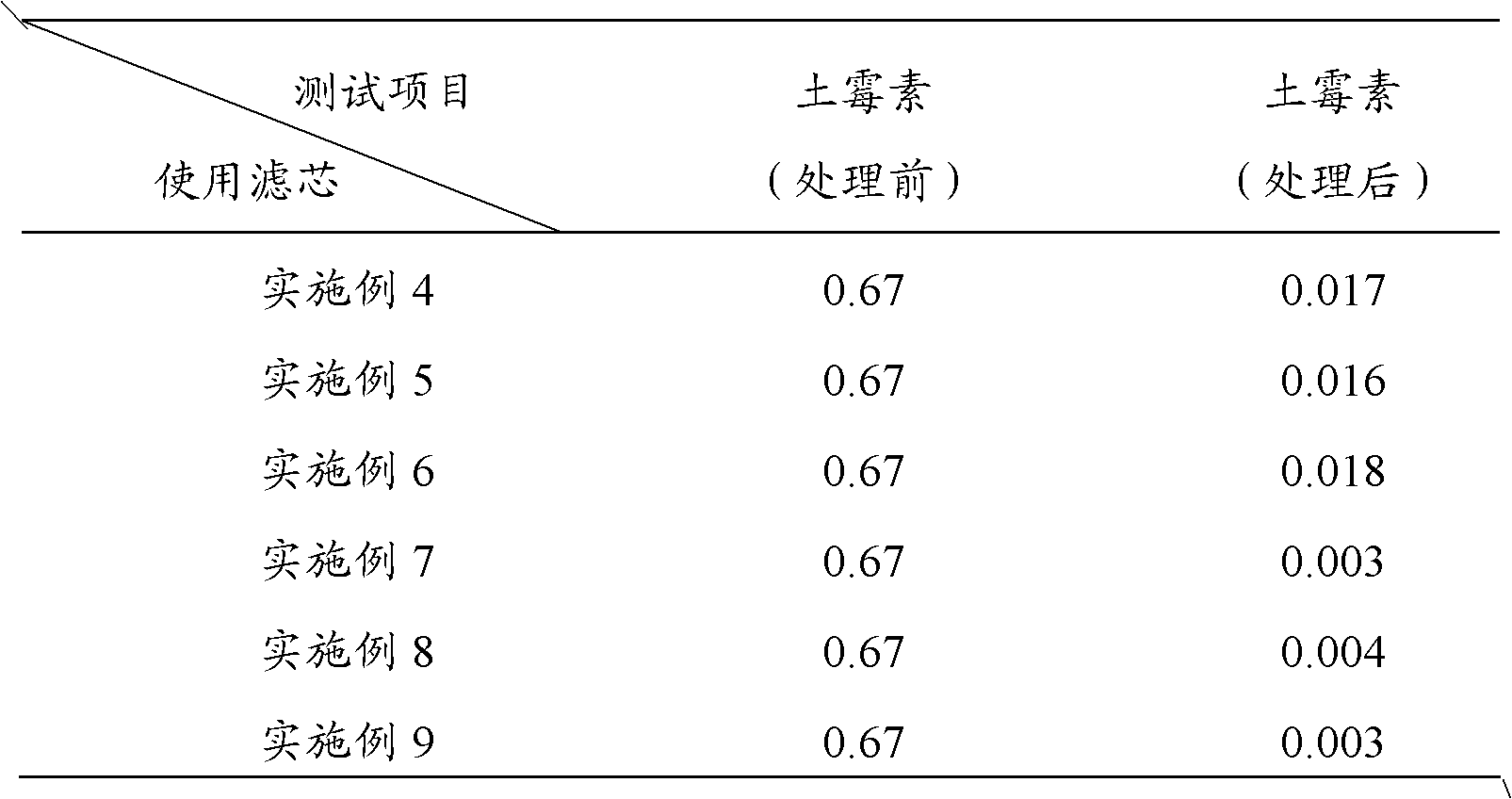

Examples

preparation example Construction

[0024] A kind of preparation method embodiment that is used to remove the filter medium of oxytetracycline in reference water provided by the present invention comprises:

[0025] a) Mixing raw materials including ultra-high molecular weight polyethylene powder, mesoporous molecular sieve powder, activated carbon powder and pore-forming agent, the specific surface area of the mesoporous molecular sieve powder is greater than 1200m 2 / g, the pore diameter is 2nm~20nm, and the pore volume is 0.5cm 3 / g~1.5cm 3 / g, the weight ratio of ultra-high molecular weight polyethylene powder, mesoporous molecular sieve powder: activated carbon powder, pore forming agent is: 100~300: 100~250: 80~110: 50~110;

[0026] b) pressing, sintering and cooling the mixture obtained in step a) in a mould.

[0027] According to the present invention, ultra-high molecular weight polyethylene (UHMWPE) is used as one of the raw materials for preparing filter media. Ultra-high molecular weight polyethy...

Embodiment 1

[0055] Get 1000g of tamarind gum powder, add 5000ml of purified water, mix and stir to obtain the first mixture;

[0056] Add 1000 g of strongly acidic cation exchange resin to the first mixture and mix to obtain the second mixture;

[0057] The second mixture is heated to boiling, solid-liquid separation, and the obtained solid particles are added to a calcium chloride aqueous solution with a mass concentration of 35% and mixed uniformly to obtain a third mixture. The weight ratio of calcium chloride to tamarind rubber powder 1:2;

[0058] The third mixture was heated to 55° C., filtered, and dried to obtain a tamarind gum composite material.

Embodiment 2

[0060] Get 1000g of tamarind gum powder, add 4000ml of purified water and mix and stir to obtain the first mixture;

[0061] In the first mixture, 1200 g of weakly acidic cation exchange resin was added and mixed to obtain the second mixture;

[0062] The second mixture is heated to boiling, solid-liquid separation, and the obtained solid particles are added to a calcium chloride aqueous solution with a mass concentration of 30% and mixed uniformly to obtain a third mixture. The weight ratio of calcium chloride to tamarind rubber powder 1:3;

[0063] The third mixture was heated to 50° C., filtered, and dried to obtain a tamarind gum composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com