GaN-based semiconductor laser and manufacturing method thereof

A gallium nitride-based, manufacturing method technology, applied in semiconductor lasers, lasers, laser parts and other directions, can solve problems such as increased defect density, high resistivity, and low hole concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

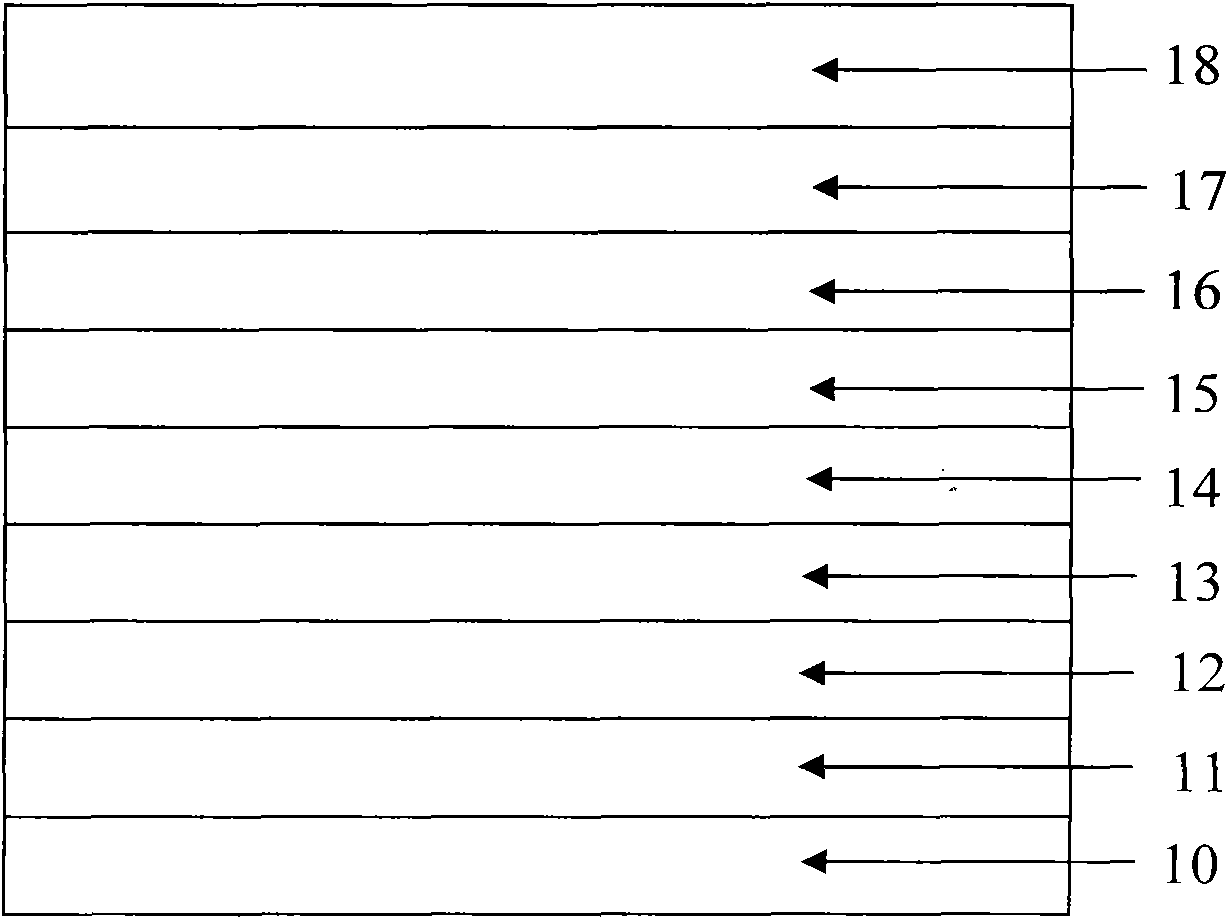

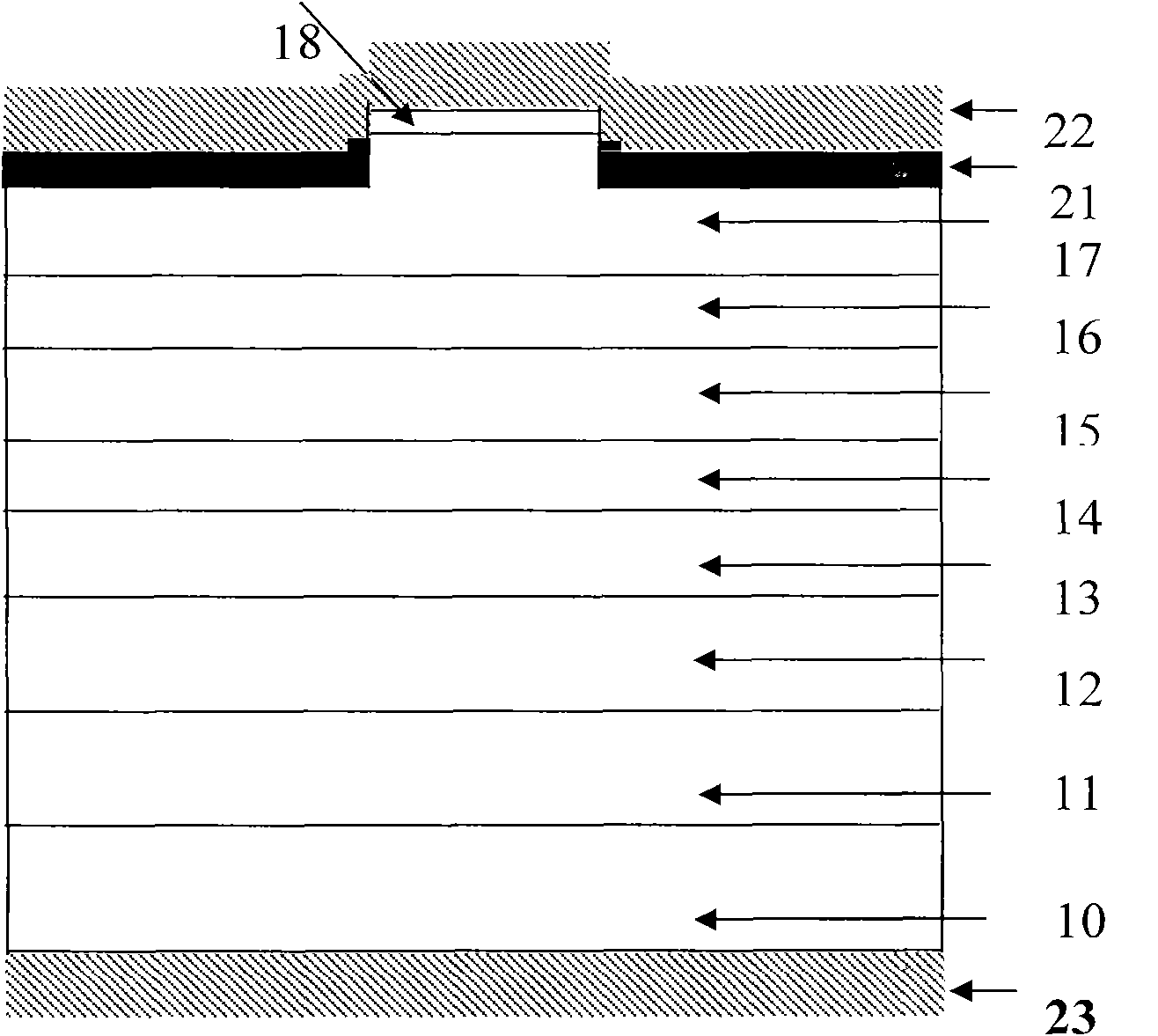

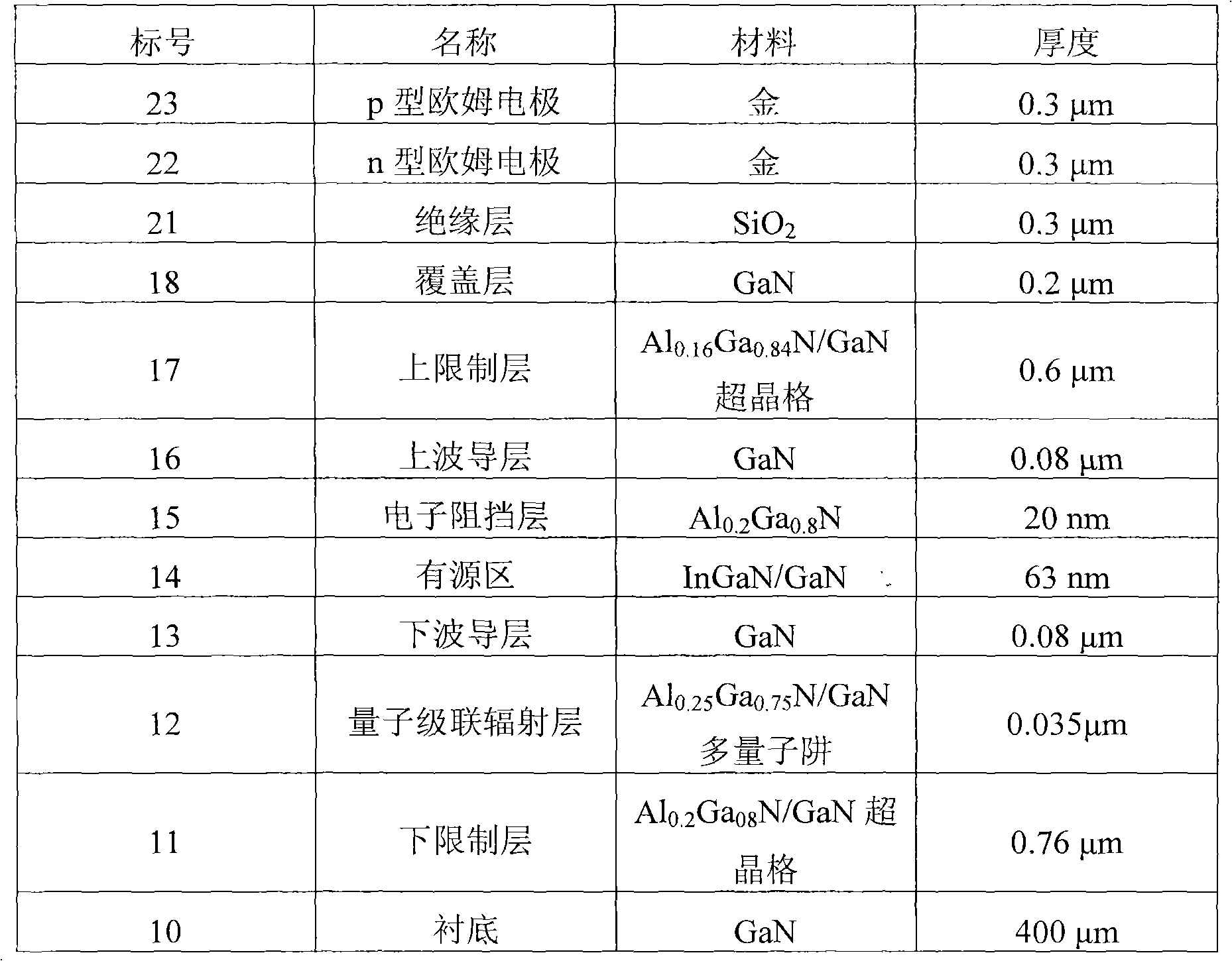

[0032] In order to further illustrate the effect of the device structure, we take a GaN-based semiconductor laser with an operating wavelength of 405nm as an example to illustrate the preparation process of the device structure. The material and thickness of each layer are shown in Table 1. The details are as follows: the device structure is grown on the n-type (0001)-plane gallium nitride substrate 10 by MOCVD method. The structure includes n-type Al 0.2 Ga 0.8 N / GaN superlattice lower confinement layer 12 (thickness is 0.76 μm, GaN well width is 2.0nm, Al 0.2 Ga 0.8 N barrier width is 2.0nm, doping concentration is 3×10 18 cm -3 ), n-type Al 0.30 Ga0.70 N / GaN multi-quantum well quantum cascade radiation layer 12 [this layer has three periods in total, and each period is Al from bottom to top 0.30 Ga 0.70 N(1.9nm) / GaN(2.6nm) / Al 0.30 Ga 0.70 N(1.9nm) / GaN(1.6nm) / Al 0.30 Ga 0.70 N(1.4nm) / GaN(1.6nm), the doping concentration is 3×10 17 cm -3 ], n-type GaN lower wave...

Embodiment 2

[0035] In order to further illustrate the effect of this device structure, as a comparison, we take a GaN-based laser with an operating wavelength of 405nm that does not include an AlGaN / GaN multi-quantum well quantum cascade radiation layer as an example. Except that the GaN-based laser device structure does not include the AlGaN / GaN multi-quantum well quantum cascade radiation layer and the thickness of the lower confinement layer is increased to 0.8 μm, the parameters, growth conditions, device dimensions and manufacturing process of other layers are completely the same as those in Example 1. same. After testing, the threshold current of the device is 110mA, and the corresponding working voltage is 7.5V. The device has a working life of only 20 hours at 1.1 times the threshold current.

Embodiment 3

[0037] In order to illustrate the application value of the present invention, we take a GaN-based semiconductor laser with an operating wavelength of 450 nm as an example to illustrate the characteristics of the device structure. Compared with Example 1, the material and thickness of each layer are changed to In except for the active area 0.3 Ga 0.7 N / In 0.02 Ga 0.98 N multiple quantum wells (multiple quantum wells are 3 periods, In 0.3 Ga 0.7 N well width is 3nm, In 0.02 Ga 0.98 N barrier width is 5nm, Si impurity concentration is 3×10 16 cm -3 ), the quantum cascade radiation layer is n-type Al 0.25 Ga 0.75 N / GaN multiple quantum wells, a total of three periods, each period is Al from bottom to top 0.25 Ga 0.75 N(2.1nm) / GaN(2.8nm) / Al 0.25 Ga 0.75 N(2.1nm) / GaN(1.8nm) / Al 0.25 Ga 0.75 N(1.6nm) / GaN(1.8nm), the doping concentration is 3×10 17 cm -3 In addition, the parameters, growth conditions, device dimensions and fabrication process of other layers are exactl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com