Integrated system for productioin of biofuel feedstock

A technology for biofuels and raw materials, applied in the field of cultivation systems for producing microalgal biomass, can solve the problem of high cost, achieve the effects of reducing pollution, overcoming seasonal climate changes, and expanding production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

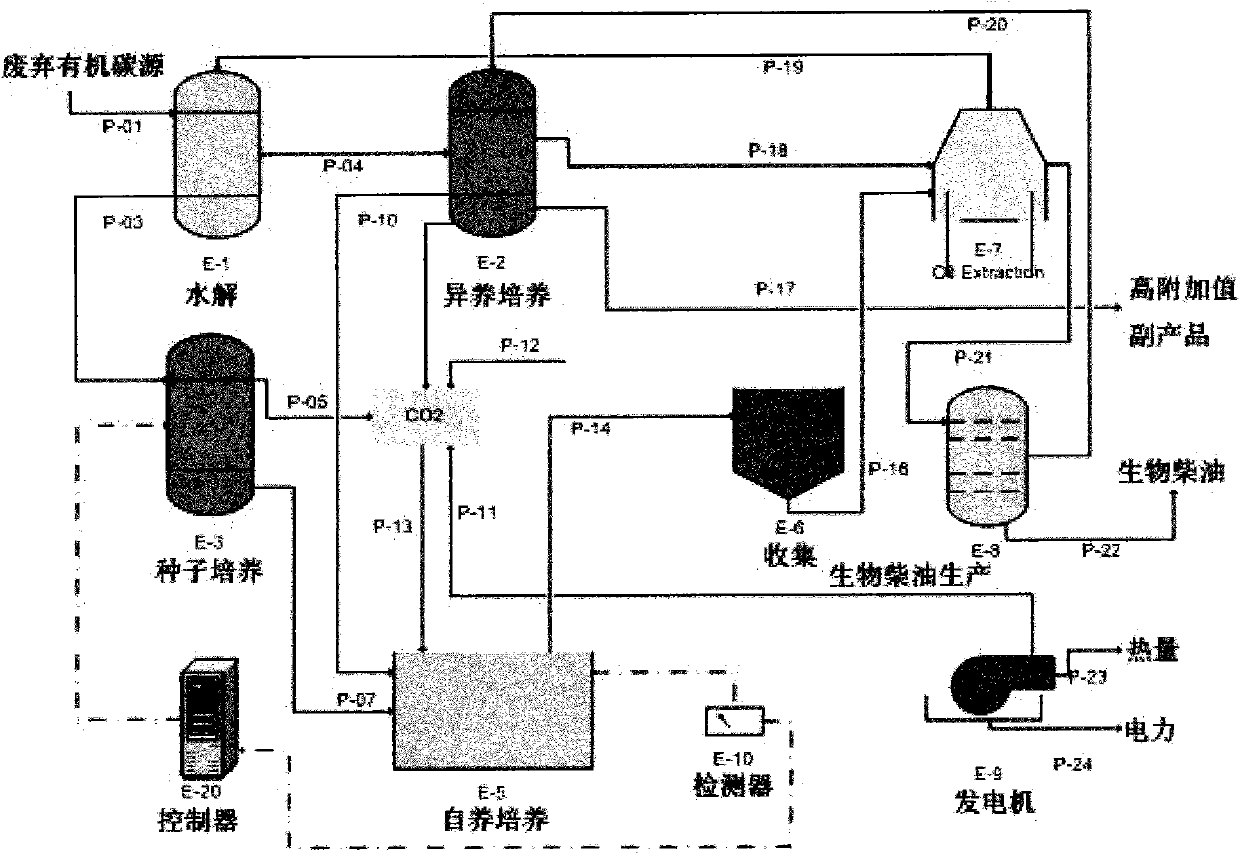

[0043] Example 1. Flowchart for a given system

[0044] figure 1 The combined heterotrophic and autotrophic culture process is summarized, including the production equipment from algae to biofuel, and Table 1 lists the key equipment and pipelines.

[0045] Table 1 figure 1 List of equipment and pipelines in

[0046]

[0047]

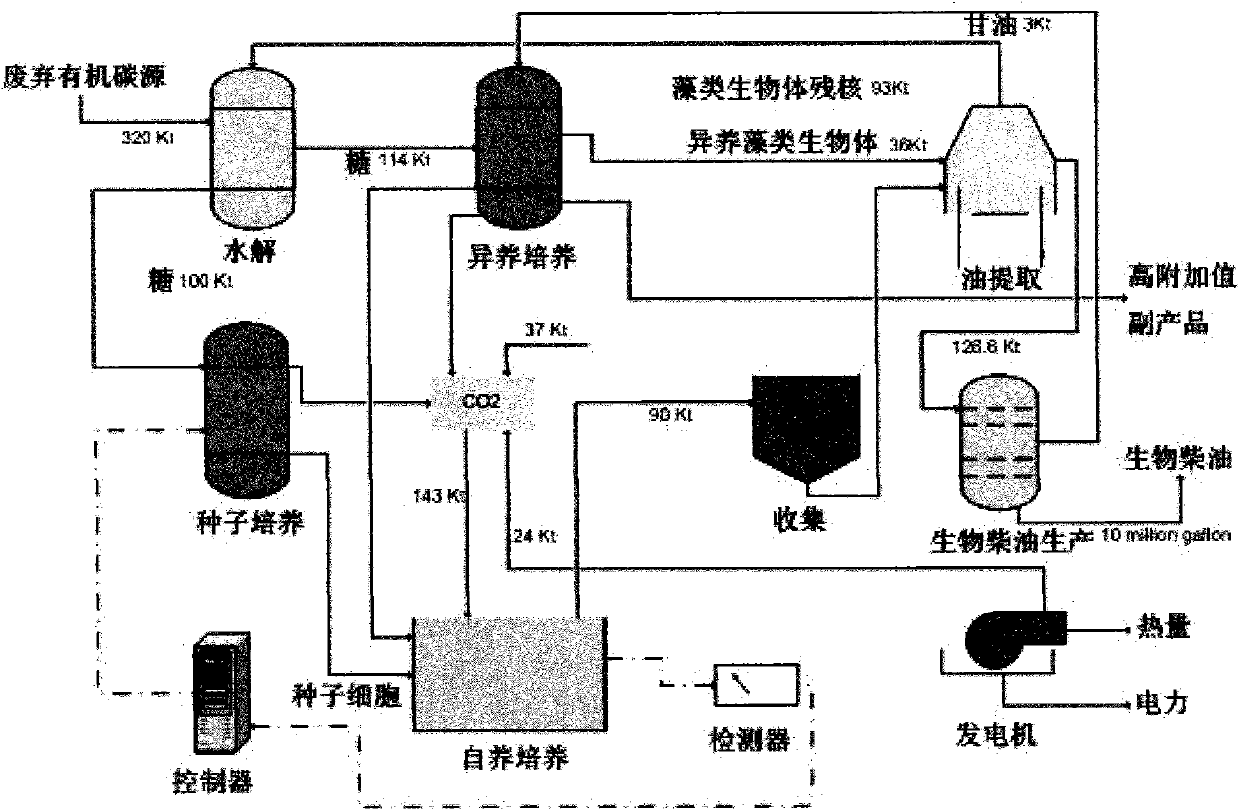

[0048] figure 2 Mass balance diagrams for each process at laboratory and pilot plant levels are depicted for this integrated process producing 10 million gallons of biodiesel and for known yields. It can be seen from the mass balance diagram that when 10MMg / yr biodiesel is produced through this process, all the nutrients and inorganic carbon required can basically meet the input of organic carbon required. Further analysis showed that 1 / 5 of the organic carbon input could be satisfied by the treated waste organic matter in the hydrolysis reactor or the direct utilization of crude glycerol. Additional inputs in the form of hydrolysis reactors ...

example 2

[0049] Example 2. Heterotrophic culture

[0050] Various organic wastes can be used as feedstock for heterotrophic culture processes. After different degrees of pretreatment, products containing oily sugars, short-chain fatty acids and / or glycerin can be obtained. Heterotrophic fermentation can be performed using these carbon sources in large-scale fermenters where pH, dissolved oxygen, and temperature are controlled in order to provide an optimal condition for cell growth and maximum cell density, these are technical operators well known. Most of the carbon and some of the nitrogen and phosphorus are consumed in the process, however, a certain amount of COD, nitrogen and phosphorus will also remain in the effluent. Fortunately, the effluent will serve as a nutrient source for autotrophic algae cultures, thereby reducing costs and increasing the reuse of system inputs. By analogy, the effluent of the final autotrophic culture process will have lower levels of COD, nitrogen ...

example 3

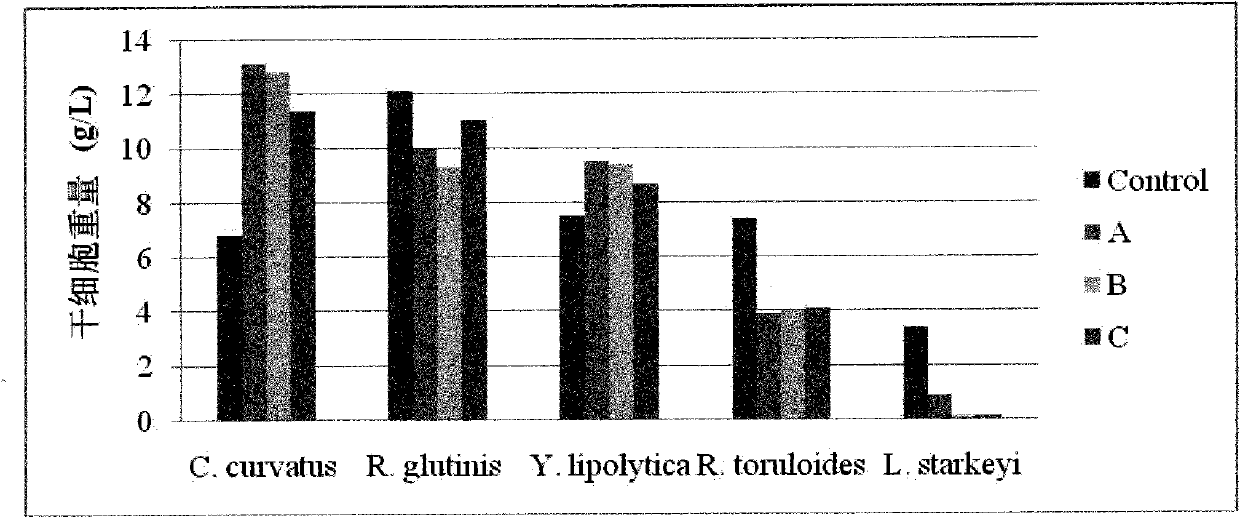

[0066] Example 3. Other algae species that can be applied to the process

[0067] In addition to Chlorella sorokiniana in Examples 2, 4 and 5, many other species of microalgae can be cultured under heterotrophic and autotrophic conditions and can be used in the processes described in Examples 1 and 2. Although experimental data on the cultivation of these microalgal strains by this process are not presented here, these microalgal species can be used as production strains because of their ability to grow autotrophically and heterotrophically.

[0068] Table 6 Algae that can grow under heterotrophic and / or autotrophic conditions

[0069]

[0070]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com