Large-scale growth fattening pig premix and preparation method thereof

A technology for growth and fattening and pig premix, which is applied in the direction of animal feed, animal feed, additional food elements, etc., can solve the problems of heavy metal pollution in the environment, encourage the growth of drug-resistant microorganisms and drug-resistant strains, and the ineffectiveness of medication, etc., to solve the hazards , Improve feed utilization efficiency and reduce disease effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1 prepares large-scale 10% pig premix

[0018] Raw materials of large-scale premix according to the following ratio: soybean meal 20%, fish meal 10.5%, puffed soybean 20%, fermented soybean meal 16%, calcium carbonate 8%, calcium hydrogen phosphate 5.8%, salt 5.0%, yeast 2.0%, soda 1.2%, Bacillus subtilis 0.5%, enzyme 0.6%, additive 10% and magnesium sulfate 0.4%.

[0019] Among them, salt, yeast, additives, Bacillus subtilis preparations, enzymes, magnesium sulfate and other raw materials that do not need to be pulverized are weighed according to the proportion, and mixed with the mixer of the premixing unit for 3-6 minutes; then the mixed A good premix is weighed according to the ratio specified in the formula for each ton of finished product, and is ready to be fed in the small material feeding port. Soybean meal, fish meal, puffed soybean and fermented soybean meal are crushed by a grinder in advance, and then put into the raw material bin after crushin...

Embodiment 2

[0020] Embodiment 2 prepares large-scale 10% premix

[0021] Mix the raw materials of the premix according to the following ratio:

[0022] 20% soybean meal, 10.5% fish meal, 20% puffed soybean, 16% fermented soybean meal, 8% calcium carbonate, 5.8% calcium hydrogen phosphate, 5.0% salt, 2.0% yeast, 1.2% soda, 0.5% Bacillus subtilis, 0.6% enzyme , additives 10% and magnesium sulfate 0.4%.

[0023] Among them, salt, yeast, additives, Bacillus subtilis preparations, enzymes, magnesium sulfate and other raw materials that do not need to be pulverized are weighed according to the proportion, and mixed with the mixer of the premixing unit for 3-6 minutes; then the mixed A good premix is weighed according to the ratio specified in the formula for each ton of finished product, and is ready to be fed in the small material feeding port. Soybean meal, fish meal, puffed soybean and fermented soybean meal are crushed by a grinder in advance, and then put into the raw material bin after...

Embodiment 3

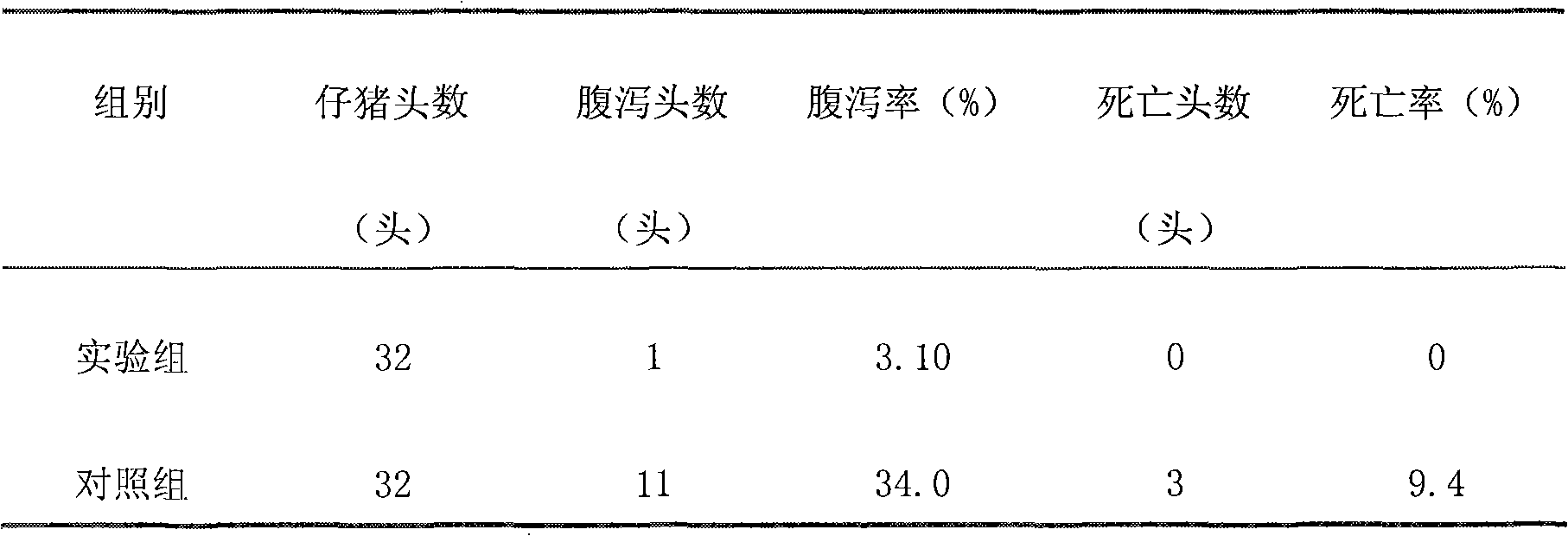

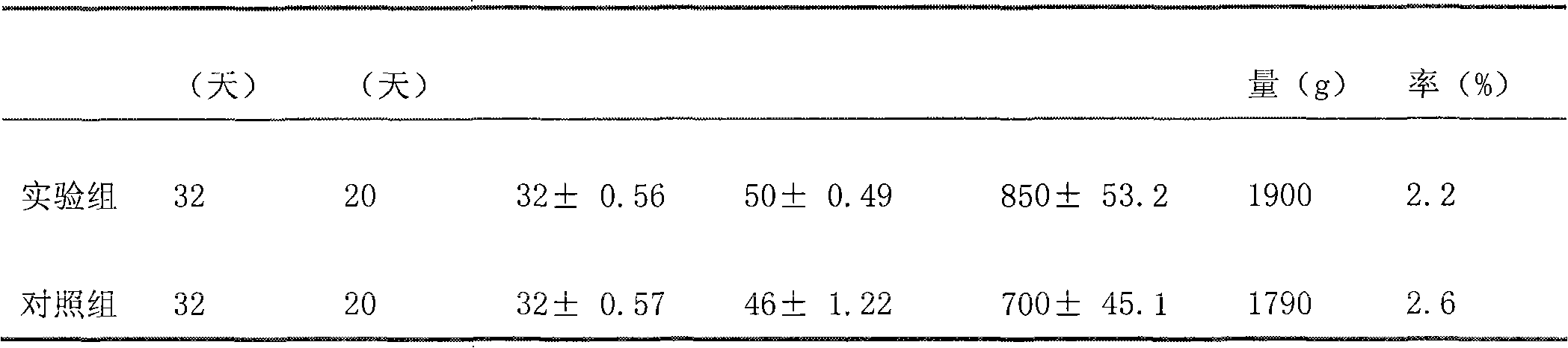

[0024] The feeding effect test of embodiment 3 large-scale 10% premix

[0025] Large-scale premix among the present invention and conventional premix comparative test

[0026] Test time: June 2, 2010----June 22, 2010

[0027] Test location: Beijing Resources Asia-Pacific Pig Breeding Farm

[0028] Test indicators: diarrhea rate, daily gain, feed conversion rate

[0029] Grouping of test pigs: The test pigs were provided by a pig farm in this town. The same parity (6th parity) of the sows was grown and fattened pigs. There was little difference. Sixty-four hybrid piglets weaned at the age of 70 days were randomly divided into two groups, namely 10% premix (test group) and conventional 4% premix group (control group). The test period was 70-90 days old, a total of 20 days.

[0030] Basic ration: refer to the relevant information, prepare the same large-material ration according to the nutritional requirements of growing pigs.

[0031] Observation records: piglets were weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com