Method for removing thiophene sulfur-containing compound from petroleum

A compound, thiophene technology, applied in the field of petroleum oil alkylation desulfurization, can solve the problem of low selectivity, achieve high catalytic activity, low polymerization activity, and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

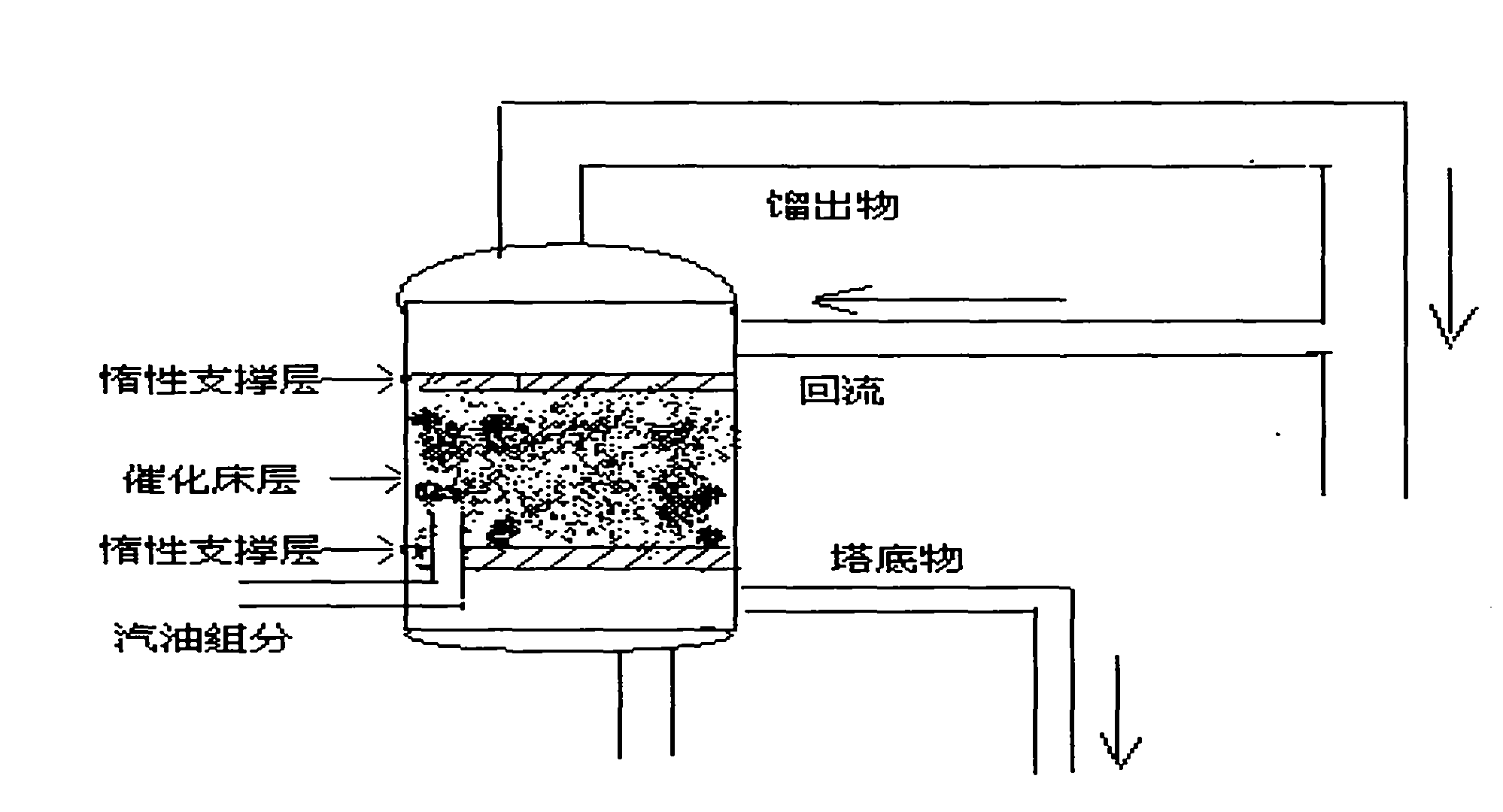

Image

Examples

Embodiment 1

[0046] complexed with Fe 3+ Preparation of ionic cation exchange resin (NKC-9) catalyst:

[0047] Convert macroporous sulfonated styrene-diethylene copolymerized cation exchange resin into hydrogen-type resin, wash and dry with distilled water, take 30g into a 250ml three-hole flask, add 250ml, 1,2-dichloroethane, heat to 30°C Stir for 12 hours to fully swell the resin particles, then add 30g FeCl 3 , reacted under reflux for 16 hours, so that Fe 3+ A complex reaction occurs between the ions and the sulfonate groups in the resin skeleton, the resin is filtered out, washed with 1,2-dichloroethane until the filtrate is clear, the resin is taken out, dried in vacuum at 60°C for 24 hours, and set aside.

Embodiment 2

[0049] Alkylation desulfurization test:

[0050] In a stirred high-pressure reactor, add 150 grams of naphtha raw materials with a boiling point range of 62-210 ° C, complexed with Fe 3+ 0.48 g of strong acidic cation exchange resin catalysts of ions were reacted for 1 minute at a temperature of 180° C. and a pressure of 6 atmospheres. The reaction products were separated by gas chromatography based on differences in boiling points. The sulfur content in the distillate was detected by a sulfur chemiluminescence detector, and the sulfur content of the gasoline component with a boiling point of 62-177° C. was 18.5 ppm.

Embodiment 3

[0052] Alkylation desulfurization test:

[0053] In a stirred autoclave, add 120 g of simulated gasoline components composed of octane, benzothiophene, and 2-methylbutene, the sulfur content of which is 850 ppm, and then add 0.56 g of complexed Fe 3+ The strongly acidic cation exchange resin of ions was reacted for 2 minutes at a stirring speed of 500 rpm, 204° C., and 10 atmospheric pressure. The reaction products were separated by gas chromatography based on differences in boiling points, and the sulfur content in the fractions was determined with a sulfur chemiluminescence detector. The sulfur content of components within the boiling range of gasoline at the boiling point is reduced to 15ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com